Automatic production line for arc chamfering of permanent magnetic ferrites and implementation method of automatic production line

An automatic production line, permanent magnet ferrite technology, applied in the direction of grinding feed movement, grinding machine, grinding machine tool parts, etc., can solve the problems of low automation degree of chamfering machine, easily damaged motor adjustment, long time for changing specifications, etc. , to achieve the effect of simple structure, high reliability and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

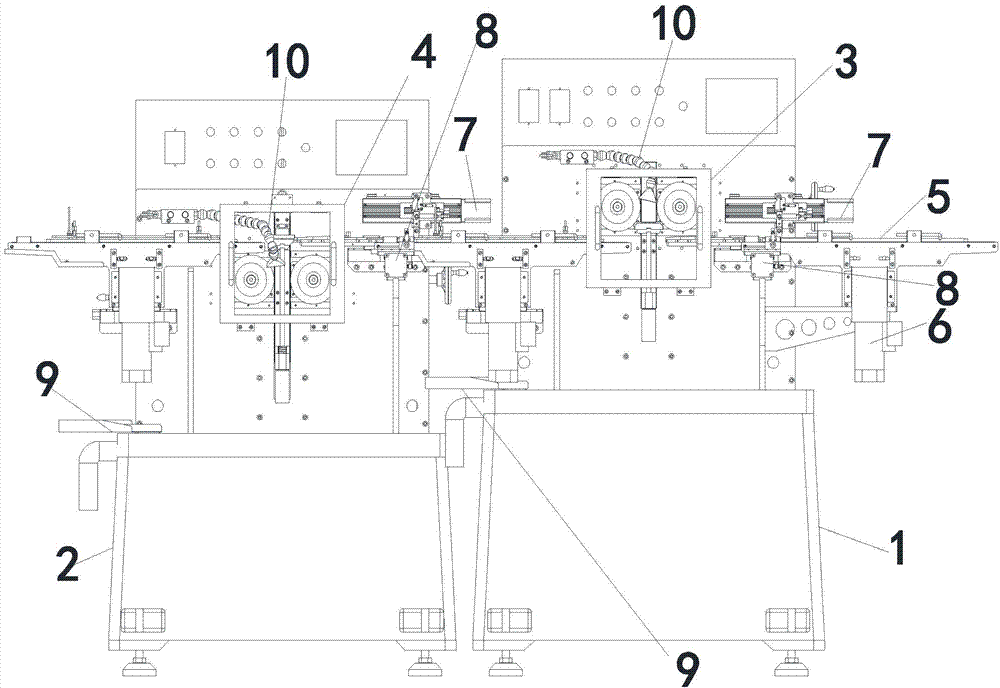

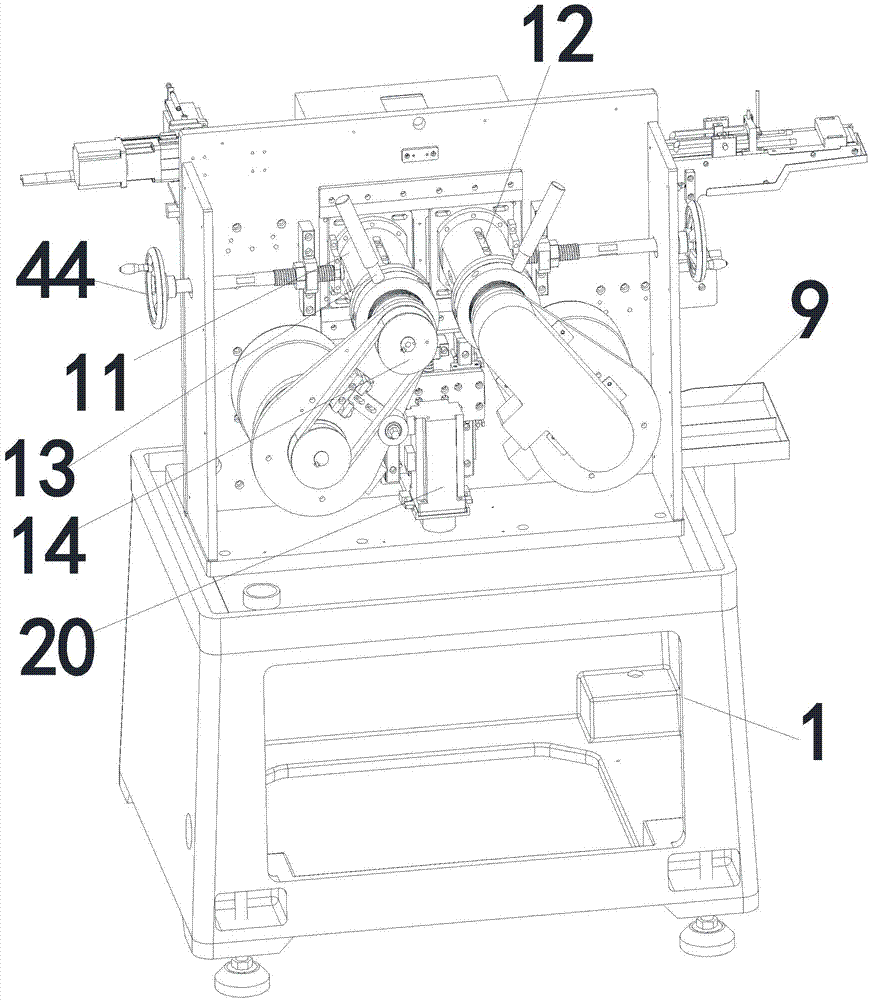

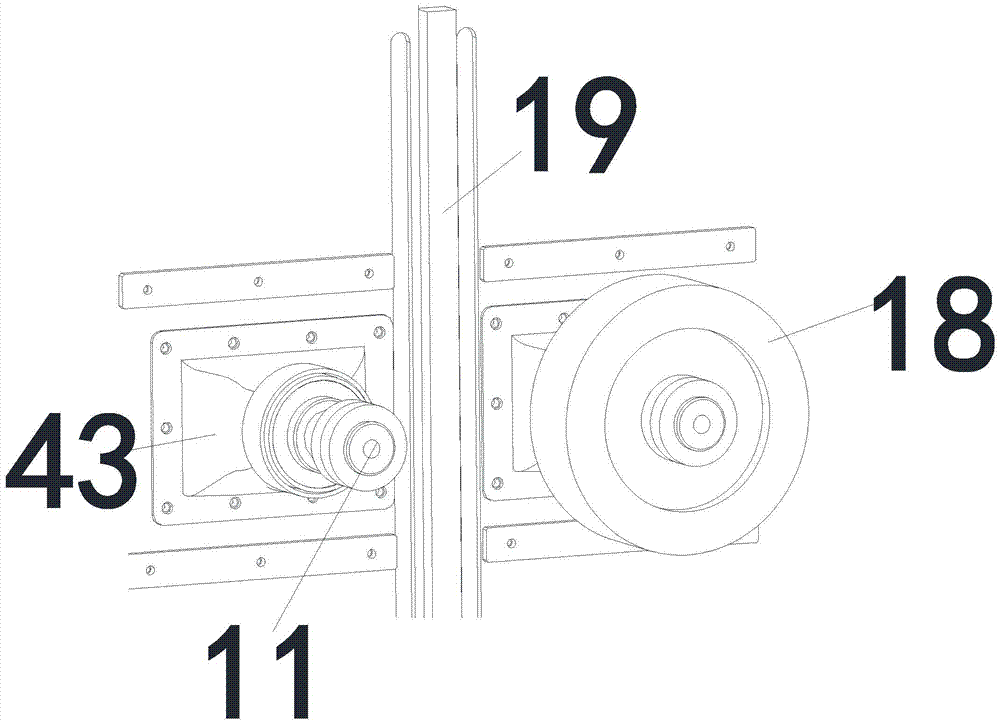

[0049] Such as Figure 1 to Figure 9 As shown, a curved permanent magnet ferrite chamfering automatic production line includes an outer arc chamfering frame 1 and an inner arc chamfering frame 2, the outer arc chamfering frame 1 is provided with an outer arc chamfering device 3, The inner arc chamfering device 4 is provided on the inner arc chamfering frame 2, the outer arc chamfering device 3 and the inner arc chamfering device 4 are equipped with a conveyor belt 5, the conveyor belt 5 is connected with the conveyor belt 6, and the outer arc chamfering The conveyor belt 5 at the entrance of the corner device 3 and the inner arc chamfering device 4 is respectively provided with a horizontal pushing device 7 and a longitudinal pushing device 8, and the frame below the outer arc chamfering device 3 and the inner arc chamfering device 4 A water receiving tank 9 is provided on the top, and a water inlet pipe 10 is respectively provided on the frame corresponding to the outer arc c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap