Automatic lifting and parallel shift type automobile chassis device

An automobile chassis and automatic lifting technology, applied in the direction of vehicle reassembly, vehicle maintenance, transportation and packaging, can solve the problems of difficult control, difficult to solve parking spaces, difficult to achieve, etc., and achieves wide popularization and application, low manufacturing cost, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

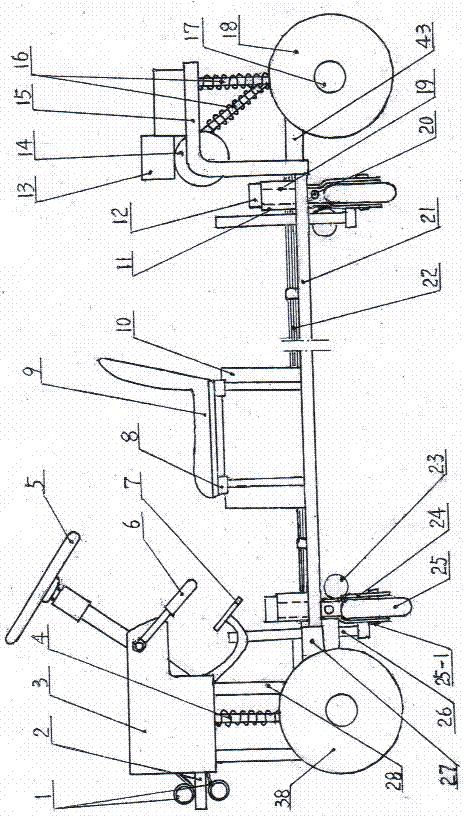

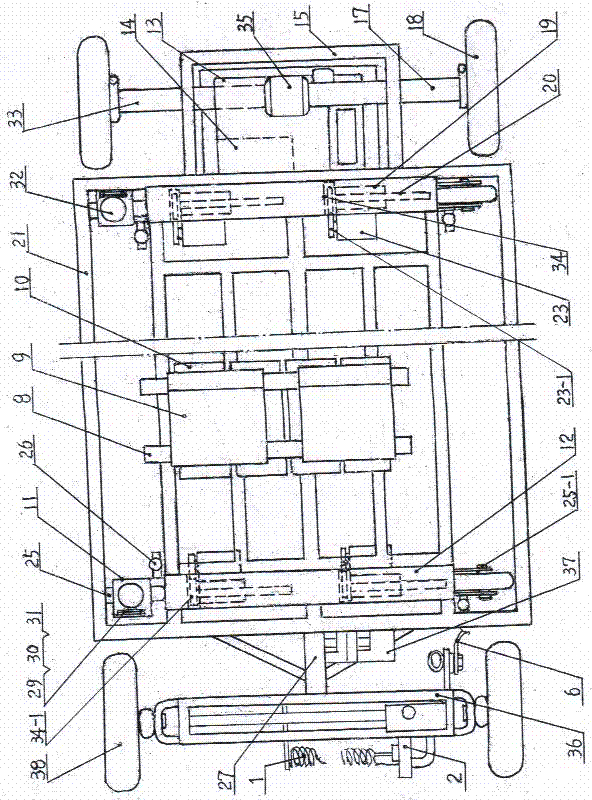

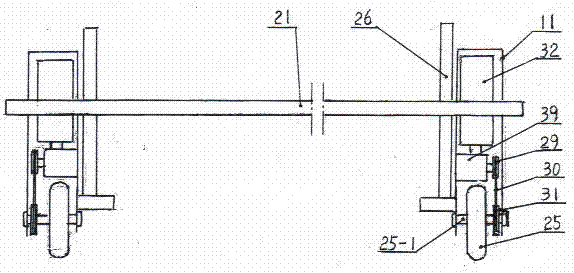

[0013] Examples, see attached Figure 1~5 , the automatic lifting parallel shifting type automobile chassis device is fixedly connected to the front suspension support frame 27 at the front end of the vehicle frame 21, and a motor controller 37 is housed above the front suspension support frame 27 and in front of the vehicle frame 21. Vertically connect preceding traveling wheel frame 36 on the front end of bracing frame 27, front traveling wheel 38 is housed on the two ends of preceding traveling wheel frame 36. Front wheel shock absorber 4 is provided with above the middle of front wheel frame 36, and front frame bracing frame 28 is housed on the longitudinal both sides of front wheel shock absorber 4, and front frame bracing frame 28 is provided with front frame 3. A brake master cylinder 2 is installed on the front of the front frame 3, and a brake oil pipe 1 is arranged on the top and bottom of the brake master cylinder 2. A steering wheel 5 is housed in the back of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com