Preparation method for multilayered graphene film

A graphene film and multi-layer graphene technology, applied in the field of material preparation and processing, can solve the problems of unsuitable layer-by-layer transfer of multi-layer graphene, weakened doping effect, etc., and achieve the effect of avoiding polymer residue and prolonging effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

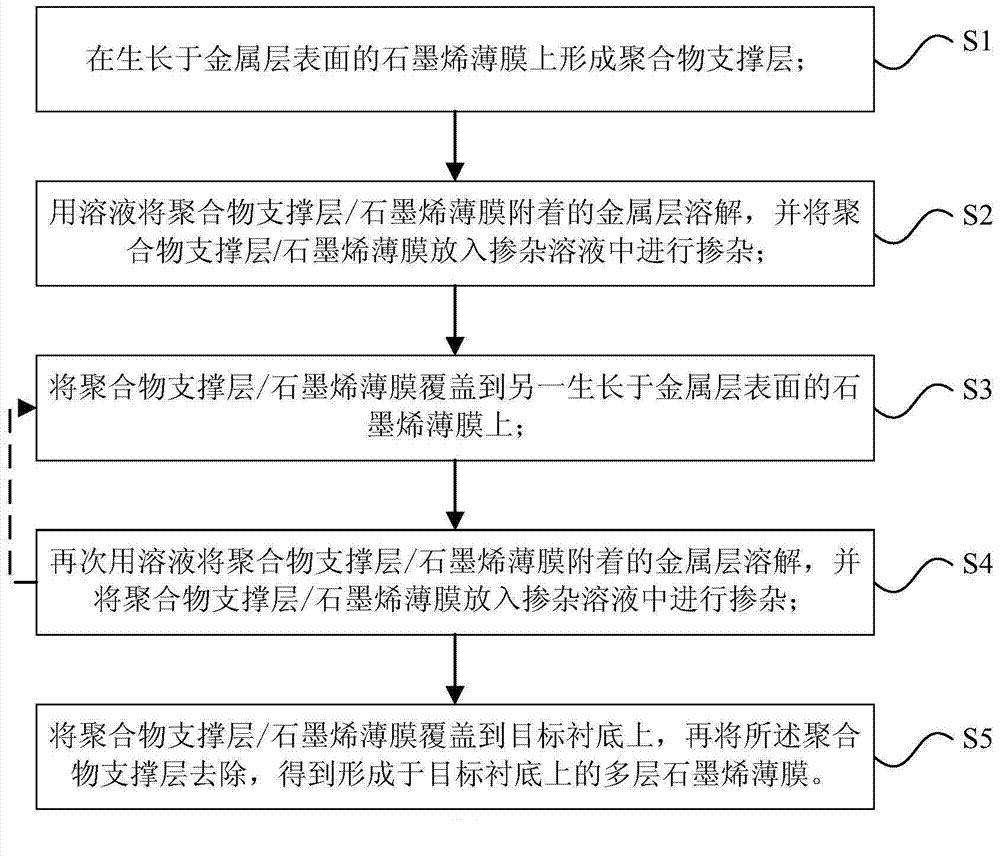

[0063] The present invention provides a kind of preparation method of multilayer graphene film, please refer to figure 1 , shown as a process flow diagram of the method, comprising the following steps:

[0064] S1: forming a polymer support layer on the graphene film grown on the surface of the metal layer;

[0065] S2: Dissolving the metal layer attached to the polymer support layer / graphene film with a solution, and putting the polymer support layer / graphene film into the doping solution for doping;

[0066] S3: covering the polymer support layer / graphene film on another graphene film grown on the surface of the metal layer;

[0067] S4: Dissolving the metal layer attached to the polymer support layer / graphene film with the solution again, and putting the polymer support layer / graphene film into the doping solution for doping;

[0068] S5: covering the polymer support layer / graphene film on the target substrate, and then removing the polymer support layer to obtain a multi...

Embodiment 2

[0094] This embodiment adopts basically the same technical scheme as that of Embodiment 1, the difference is that in Embodiment 1, the steps S2 to S3 are only performed once to obtain a double-layer graphene film located on the surface of the target substrate; and this embodiment In the embodiment, after step S4 is performed, steps S3-S4 are repeated at least once to prepare a three-layer or more graphene film on the surface of the target substrate.

[0095] Specifically, such as figure 1 Shown, the preparation method of described multilayer graphene film comprises the following steps:

[0096] S1: forming a polymer support layer on the graphene film grown on the surface of the metal layer;

[0097] S2: Dissolving the metal layer attached to the polymer support layer / graphene film with a solution, and putting the polymer support layer / graphene film into the doping solution for doping;

[0098] S3: covering the polymer support layer / graphene film on another graphene film grow...

Embodiment 3

[0105] This embodiment adopts basically the same technical solution as Embodiment 1 or Embodiment 2. The difference is that in Embodiment 1 and Embodiment 2, in the step S1 or step S3, the growth on the surface of the metal layer The graphene films are all single-layer graphene, and the finally obtained multi-layer graphene film on the target substrate is formed by stacking a plurality of doped single-layer graphene; and in the present embodiment, in the step S1 Or in step S3, the graphene film grown on the surface of the metal layer can be single-layer graphene or multi-layer graphene (including double-layer graphene).

[0106] In this embodiment, the finally obtained multilayer graphene film on the target substrate can be formed by stacking multiple doped single-layer graphene and doped multilayer graphene, or can be formed by multiple It is made of doped multi-layer graphene. Although there are no doped ions between some layers of graphene films, the doped ions between othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com