Low heat conduction polystyrene heat insulation material

A technology of polystyrene and thermal insulation materials, applied in the field of thermal insulation materials, can solve the problems of high thermal conductivity, large quantity of thermal insulation materials, and high cost of thermal insulation systems, and achieve the effects of reducing thermal conductivity, volumetric density, and types of additions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

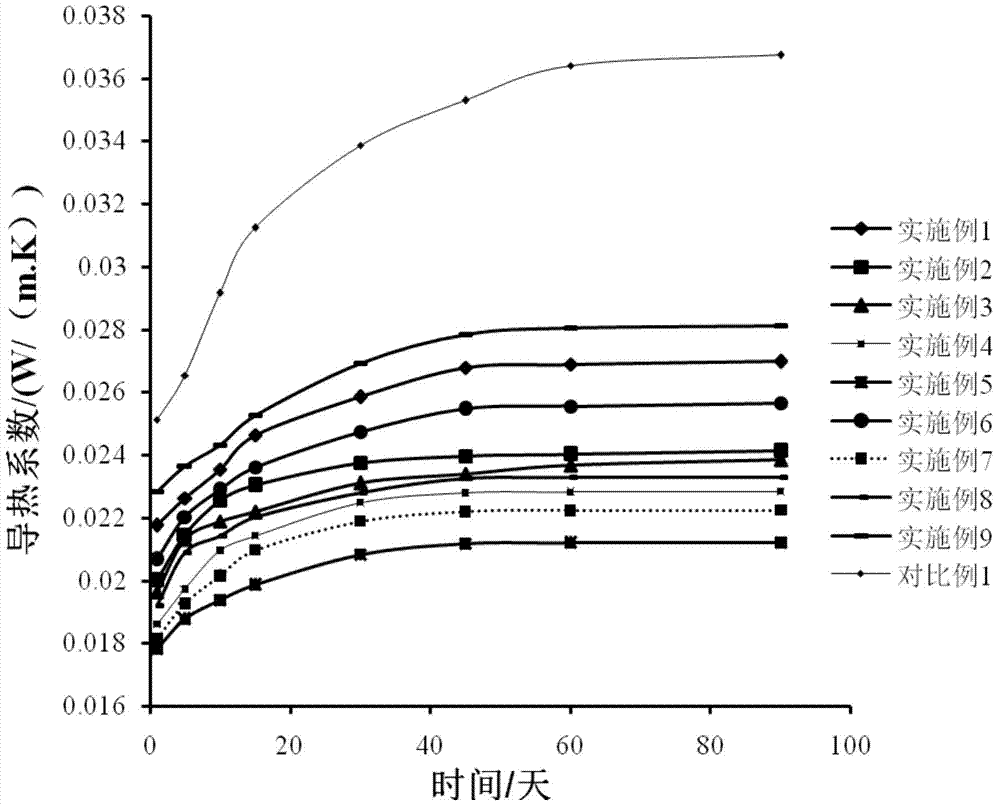

Embodiment 1

[0035] A low thermal conductivity extruded polystyrene insulation material, the raw materials of which include:

[0036] 100kg of polystyrene, 0.5kg of flaky graphite powder, 0.5kg of low molecular weight polystyrene particles, 9kg of blowing agent, and 8kg of flame retardant. The blowing agent includes: 4kg of carbon dioxide, 1.6kg of cyclopentane, and 3.4kg of tetrafluoroethane.

Embodiment 2

[0038] A low thermal conductivity extruded polystyrene insulation material, the raw materials of which include:

[0039] 400kg of polystyrene, 4kg of flaky graphite powder, 3.6kg of low molecular weight polystyrene particles, 42kg of foaming agent, and 30kg of flame retardant. The blowing agent includes: 4kg of carbon dioxide, 8kg of cyclopentane, and 30kg of tetrafluoroethane.

Embodiment 3

[0041] A low thermal conductivity polystyrene insulation material, the raw materials of which include:

[0042] 200kg of polystyrene, 4kg of flaky graphite powder, 3.2kg of low molecular weight polystyrene particles, 20kg of foaming agent, and 12kg of flame retardant. The blowing agent includes: 3kg of carbon dioxide, 4.4kg of cyclopentane, and 12.6kg of tetrafluoroethane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap