220kv four-circuit cable terminal narrow-base steel tube tower

A cable terminal, 220kv technology, used in towers, building types, buildings, etc., can solve the problems of a large number of wire and cable conversion loops, complex design processes, large footprint, etc., to reduce corridor width, meet process requirements, Small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

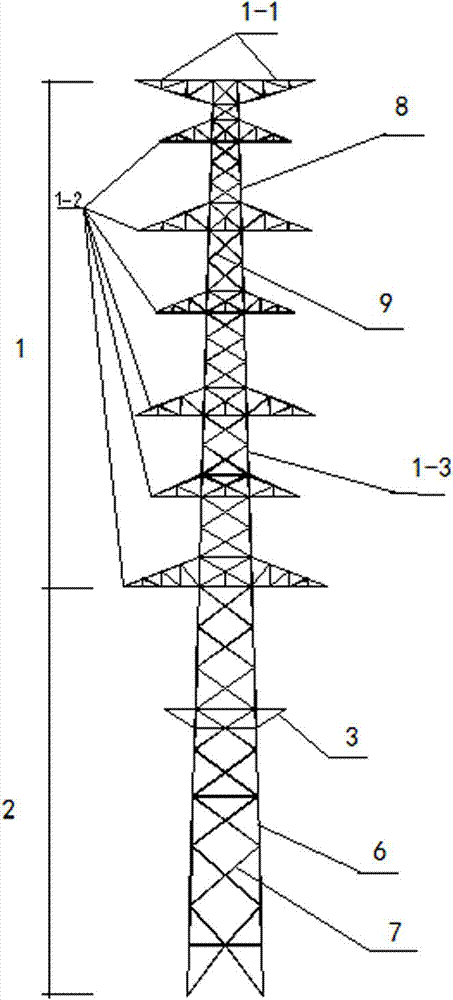

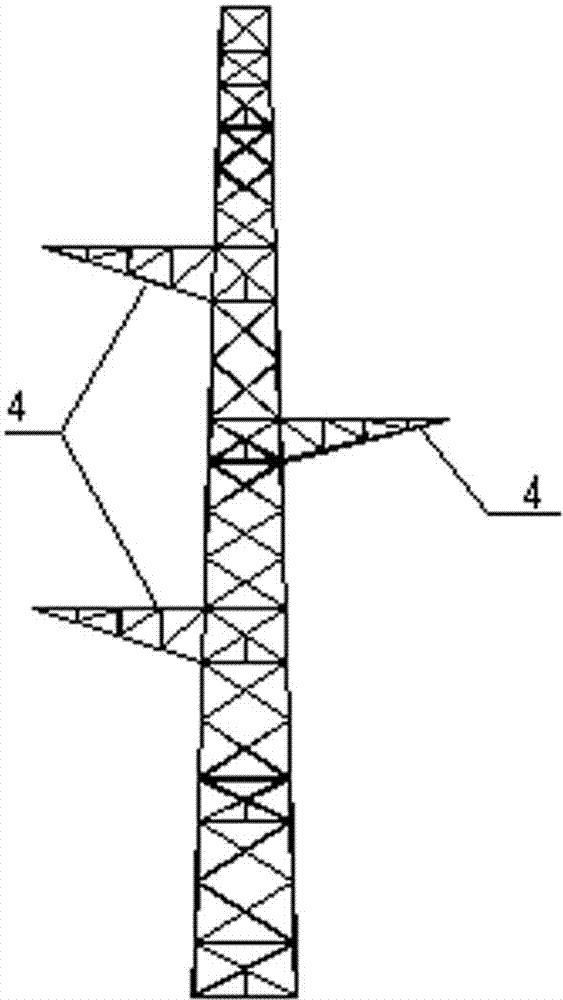

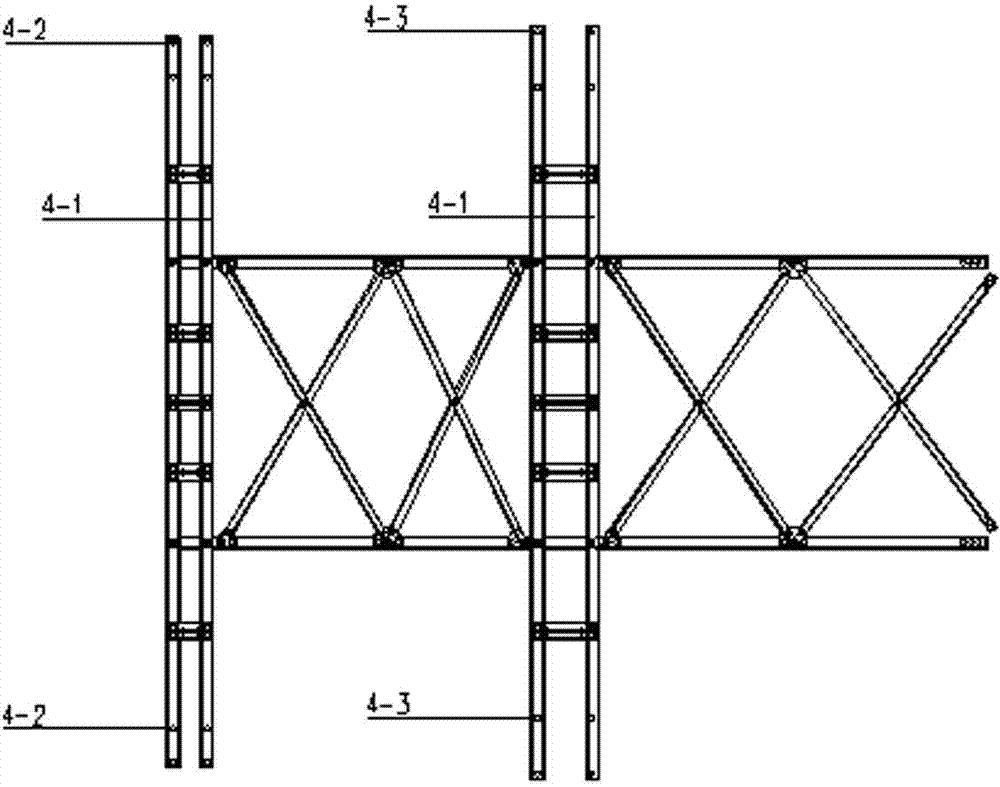

[0028] Referring to Figure 1(a) and Figure 1(b), the 220kV four-circuit cable terminal narrow-base steel pipe tower in this embodiment includes a tower head 1 and a tower body 2, and the tower head 1 is composed of a ground wire bracket for hanging the ground wire 1-1. The wire cross arm 1-2 and the tower head body 1-3 are composed. The ground wire support 1-1 is set on the top of the tower head body 1-3, and the two ends of the wire cross arm 1-2 respectively protrude from the tower head body 1. On both sides of -3, the number of conductor cross arms 1-2 is at least two, and each conductor cross arm 1-2 is arranged on the tower head body 1-3, and also includes a cable platform 3 and at least one cable down-lead bracket 4, and the cable The downlead support 4 is horizontally arranged on the outer periphery of the tower head body 1-3, the cable platform 3 is arranged at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com