Noise weakening processing method for exhaust gas emission pipe

A technology of exhaust emission and treatment method, which is applied in the direction of mufflers, exhaust devices, engine components, etc., can solve the problems of insignificant noise treatment effect, poor low-frequency noise effect, and large power loss of muffler, so as to reduce the residual air flow Possibility, reduce impact or corrosion, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

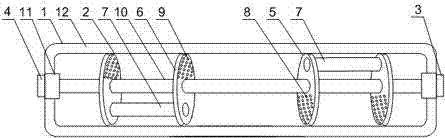

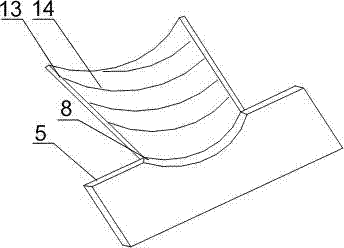

[0030] Such as figure 1 with figure 2 As shown, this embodiment includes the following steps:

[0031] (A) The exhausted air flow is passed into the ventilation pipe through the air inlet, and the pneumatic control valve can control the flow direction of the air flow according to the size of the air flow;

[0032] (B) When the air flow exceeds a certain limit, the pneumatic control valve is opened, and the air flow directly enters the space formed by the first partition plate and the muffler wall from the air inlet, and most of the air flow enters the second through the connecting pipe. The space between the two partitions and the baffle, and the remaining part of the airflow is silenced step by step by the through holes on the two partitions;

[0033] (C) The sound-absorbing protrusions silence the noise filtered through the through holes. When the airflow flows through the through-holes through the sound-absorbing protrusions, the volume of the airflow changes suddenly, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com