Engine intake and exhaust control system and method

A technology of a control system and a control method, applied in the directions of engine control, electrical control, engine components, etc., can solve the problems of large size and weight of the supercharger, poor acceleration performance of the engine, large volume of the supercharger cavity, etc. Transient response performance, the effect of realizing intake air pressure ratio and increasing intake air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

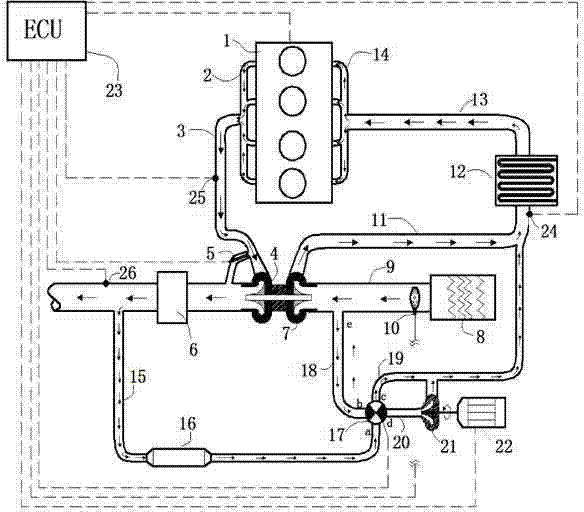

[0035] Such as figure 1 As shown, an engine intake and exhaust control system includes an engine 1 , an engine ECU 23 , an exhaust gas turbocharger, an air path control valve 17 and a double-effect pump 21 .

[0036] One end of the engine 1 is connected with an intake pipe 13 through an intake manifold 14 , an air cooler 12 is arranged on the intake pipe 13 , and the other end of the intake pipe 13 is connected with the intake manifold 11 . The other end of the engine 1 is connected with an exhaust manifold 3 through an exhaust manifold 2 . The intake manifold 11 is preferably provided with an intake manifold pressure sensor 24 for detecting the pressure of the fluid in the intake manifold 11 and transmitting the measured pressure to the engine ECU 23 in time. The exhaust manifold 3 is preferably provided with an exhaust m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com