Coal-fired boiler with function of suppressing nitrogen oxide emission

A technology of coal-fired boilers and nitrogen oxides, applied in the field of boilers, can solve problems such as slow fire speed, long burning time, and environmental pollution, and achieve the effects of reducing emissions, reducing harmful components, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

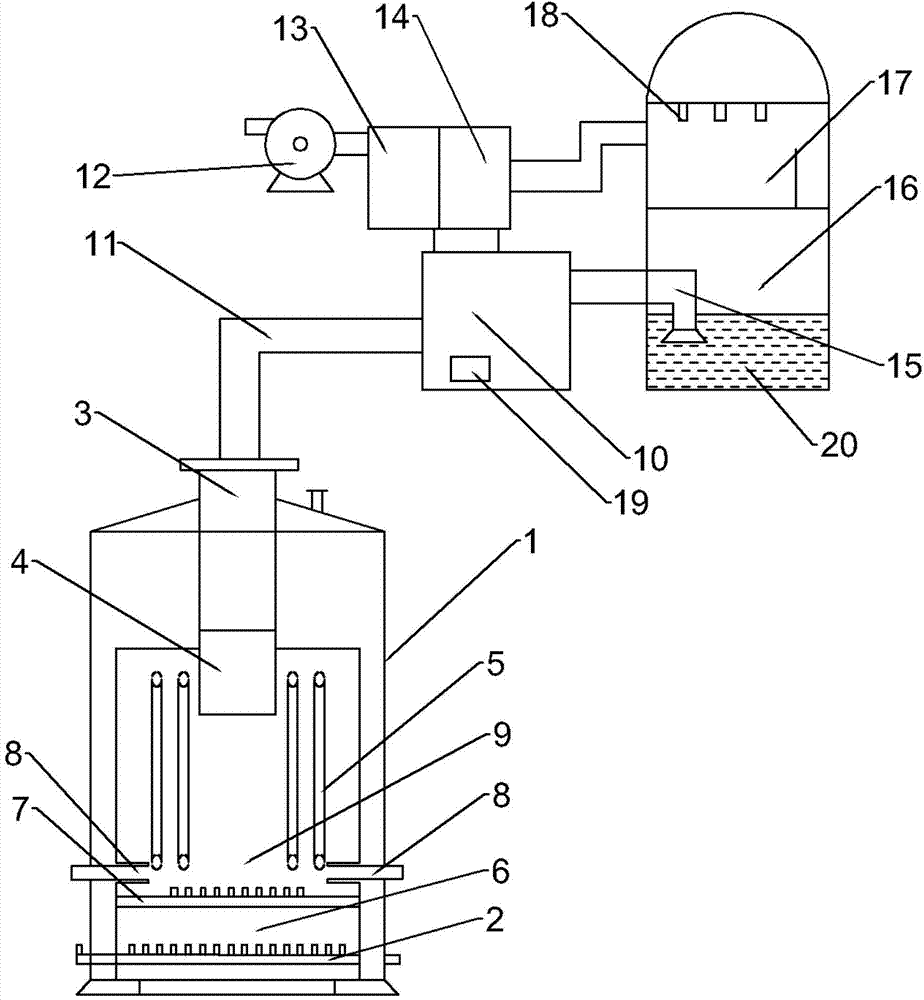

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0013] see figure 1 , a coal-fired boiler for suppressing the emission of nitrogen oxides, comprising a furnace body 1, a natural wind grate 2 located at the bottom of the furnace body 1, a chimney 3 and a dust removal tube 4 located above the furnace body 1, and the interior of the furnace body 1 is arranged symmetrically The vertical water-cooled wall 5, the secondary combustion area 6 above the natural air fire grate 2, the primary air fire grate 7 is arranged in the furnace body 1 and above the secondary combustion area 6, and the outer wall of the furnace body 1 is provided with a protruding Inside the body of furnace 1, the mechanical air channel 8 located above the primary air grate 7 is the primary air combustion zone 9 above the primary air grate 7. The gas dedusting and purifying device comprises smoke and dust inlet pipe 11, exhaust pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com