Method for controlling operation of minitype oil burner of 1050 MW ultra-supercritical pulverized coal boiler

A pulverized coal boiler and ultra-supercritical technology, which is applied in the control of combustion, lighting and heating equipment, etc., can solve the problems affecting the primary air jet direction and jet velocity of the burner, boiler fire extinguishing, and primary air duct blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

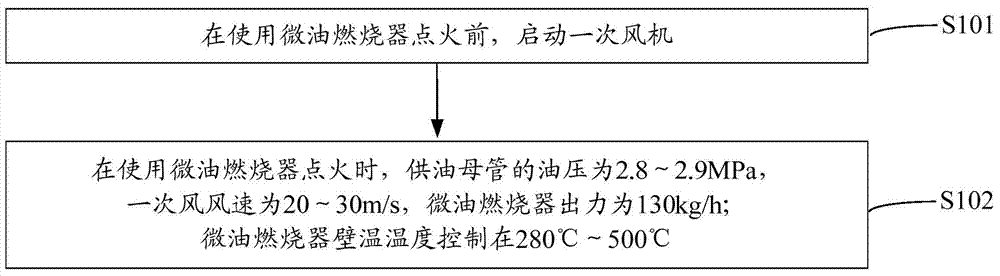

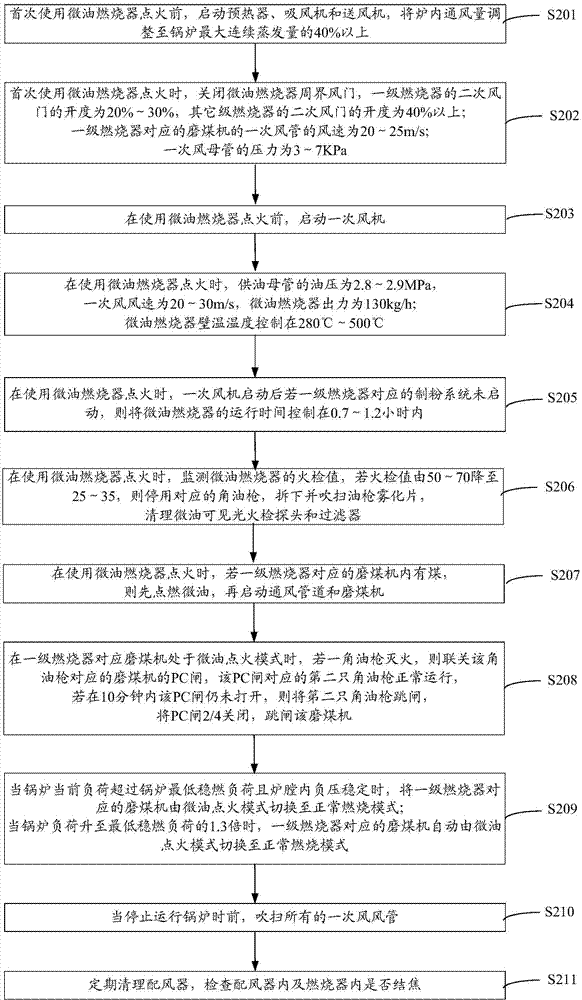

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is described by taking the 1050 MW ultra-supercritical boiler manufactured by Harbin Boiler Works Co., Ltd. as an example. The boiler model is HG-3100 / 28.25-YM4.

[0029] The burner of the boiler adopts the octagonal reverse double tangential circle combustion method without partition wall, and the full swing burner. The burner has a total of six layers of primary air outlets, three layers of oil air chambers, and twelve layers of auxiliary air chambers. The entire burner is fixedly connected to the water-cooled wall and expands downward with the water-cooled wall. Four layers of additional burn-off air nozzles are arranged 7.2m (meters) above the center line of the upper layer of pulverized coal nozzles. Each burner is equipped with three mechanical atomization oil guns, and there are 24 oil guns in the whole furnace, and each oil gun is equipped with a high-energy ignition device. The pulverizing system adopts the medium-speed grinding positive pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com