Double-discharging dynamic powder calcining furnace

A technology of dynamic calcination and double discharge, applied in the field of calciners, can solve problems such as the reduction of carbon dioxide concentration, and achieve the effects of increasing the contact area, saving energy, and fully burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

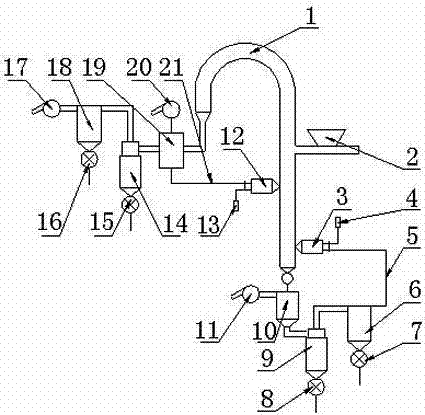

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The protection scope of the present invention is not limited to the following:

[0018] Such as figure 1 As shown, a dual-discharge powder dynamic calciner includes a calciner body 1, a raw material heater 2, a heater A3, a vacuum cleaner A6, a star discharge valve A7, a cyclone separator A9, and a star discharge valve B8, air-to-air heat exchanger A10, air cooler A11, heater B12, air-to-air heat exchanger B19, air cooler B20, cyclone separator B14, star discharge valve C15, vacuum cleaner B18, star discharge valve D16 and The tail exhaust fan 17, the heat exchanger A10, the cyclone separator A9 and the vacuum cleaner A6 are connected in series in sequence, the heat exchanger B19, the cyclone separator B14 and the vacuum cleaner B18 are connected in series in sequence, and the gas-gas heat exchanger B19 is connected above the main body of the calciner 1, In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com