Busbar voltage detecting system and fault diagnosis method based on wireless sensor network (WSN)

A bus voltage and detection system technology, applied in the electric power field, can solve the problems of insufficient battery supply voltage, increased cost, high cost, etc., to avoid the inability to collect and transmit data in real time, improve work efficiency, and reduce the number of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

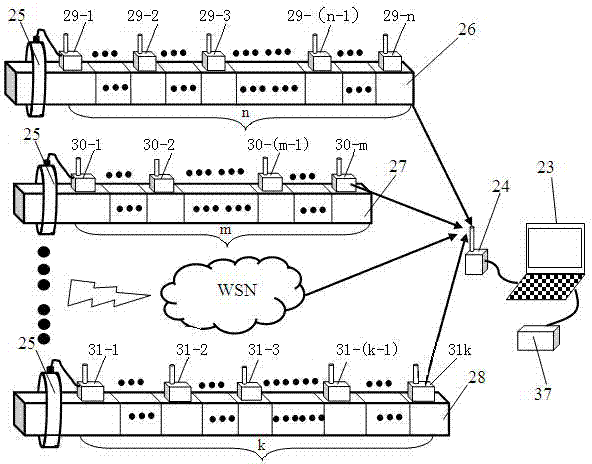

[0026] see figure 1 , in the actual power transmission project, there are N bus trunk lines, which are respectively: No. 1 bus trunk line 26, No. 2 bus trunk line 27...N bus trunk line 28. Each busbar trunk line itself contains several busbar joint units in different numbers. Install bus voltage detection nodes between the same number of bus joint units on each bus trunk line, that is, bus voltage detection nodes and other bus joint units are installed at intervals, and the bus joints between every two adjacent bus voltage detection nodes The number of units is equal, which facilitates the detection of the entire bus voltage.

[0027]On the No. 1 bus trunk line 26, there are n identical bus voltage detection nodes distributed sequentially from left to right, which are the first bus voltage detection node 29-1, the second bus voltage detection node 29-2, and the third The bus voltage detection node 29-3...the n-1th bus voltage detection node 29-(n-1) and the last nth bus volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com