Lead-acid storage battery grid with confluence lug and super-pore cut and stretched net being welded together

A technology of lead-acid batteries and cut nets, which is applied in the direction of lead-acid batteries, lead-acid battery construction, battery pack components, etc., can solve the problems of low specific energy, poor charge and discharge performance of batteries, and low utilization rate of active materials. Achieve the effect of improving cycle life and improving charge and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

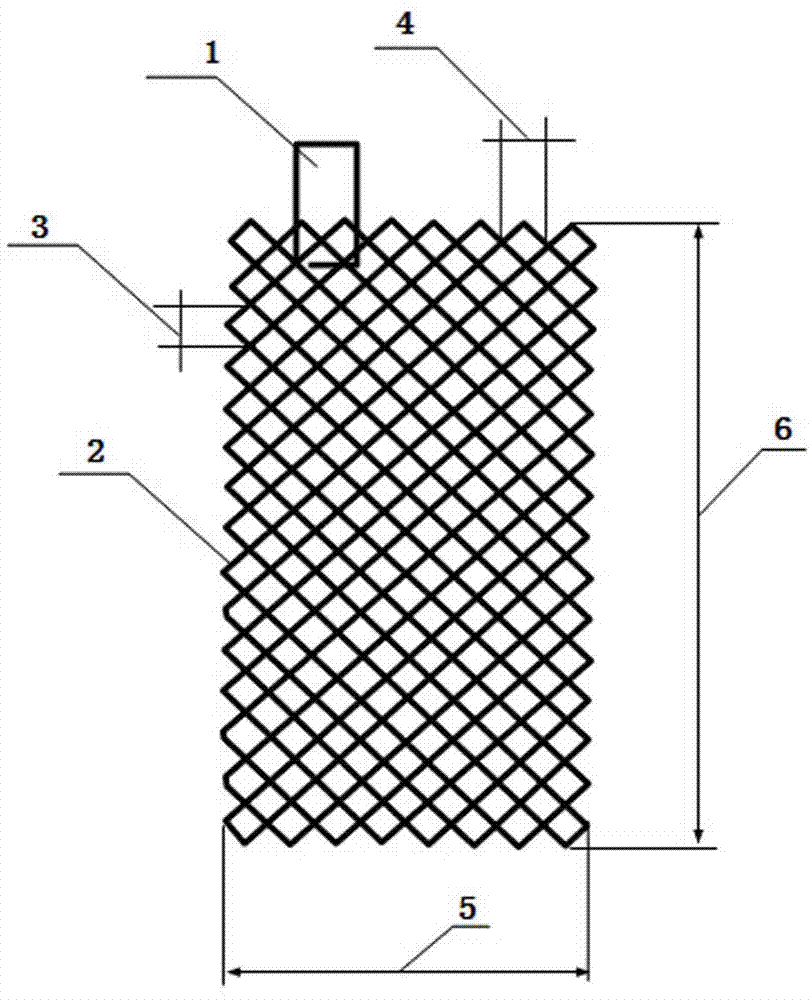

[0015] as attached figure 1 As shown, the present invention includes: bus lug 1, rib 2, hole length 3, hole width 4, grid width 5, grid length 6, the lead strip rolled from lead metal is made into ultra- Small hole lead-acid battery grid.

[0016] Said bus lugs are welded together with ultra-small-hole cut-and-pull mesh by a patch welding process.

[0017] The hole length of the ultra-small hole is between 0.5mm and 3.5mm.

[0018] The hole width of the ultra-small holes is between 0.5mm and 3.5mm.

[0019] The thickness of the lead strip is between 0.1mm-4mm.

[0020] The size of the grid ribs is between 0.2mm-1.8mm.

[0021] The lead-acid battery includes all types of lead-acid batteries such as starting type, power type, energy storage type, electric vehicle type, ship type, railway type, and military type.

[0022] The lead metal includes various lead and lead alloys such as pure lead, lead-calcium alloy, lead-calcium-tin-aluminum alloy, lead-antimony alloy, lead-stro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole length | aaaaa | aaaaa |

| Hole width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com