Polymer film circuit board and electronic component interconnection method

A technology of electronic components and polymer films, which is applied in the manufacture of electrical components, printed circuits, printed circuits, etc., can solve the problems of low glass transition temperature and achieve the effects of short assembly time, simple and reliable process, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

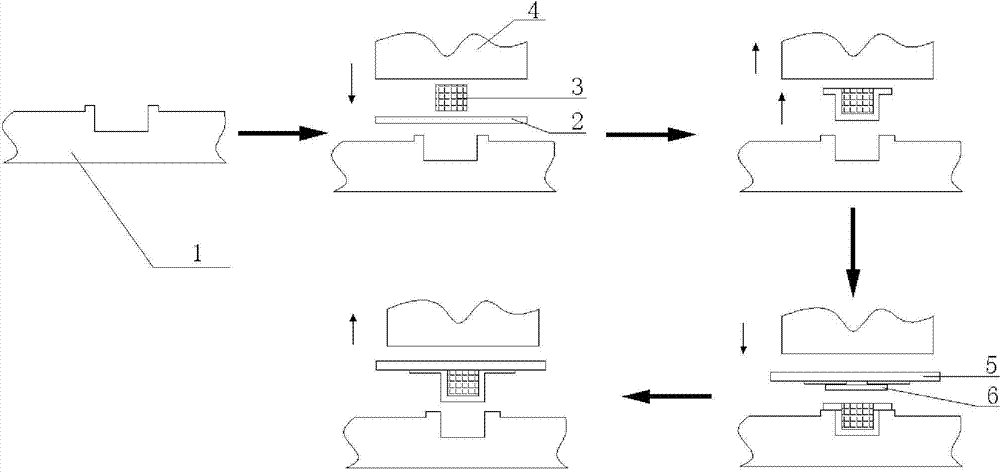

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 Shown: a kind of polymer film circuit board and the interconnection method of electronic components and parts, it is characterized in that, comprises the following steps:

[0024] (1) Design and process the concave mold 1 for placing the electronic components 3 according to the external dimensions of the electronic components; The mold 1 is made of metal material and processed by tools such as machine tools.

[0025] (2) Place a layer of polymer film 2 above the concave mold 1, place the electronic components 3 on the polymer film 2, and align with the groove of the concave mold 1, wherein the electronic components 3 The surface with metal connection pins is placed outwards, and the size of the concave mold 1 should be the sum of the outline size of the electronic component 3 and the thickness of the polymer film 2 used for packaging.

[0026...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com