Preparation method of bracken fern vermicelli

A technology of fern root powder and a processing method, which is applied in the field of preparation of fern root vermicelli, can solve the problems of easily gelatinized fern root vermicelli, reduced nutritional value, and cannot meet people's healthy living standards, etc. Economic value, effect of increasing transparency and color perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1), material selection and powder extraction: select fern root, sweet potato and potato with high starch content as raw materials, process and extract starch after cleaning for subsequent use.

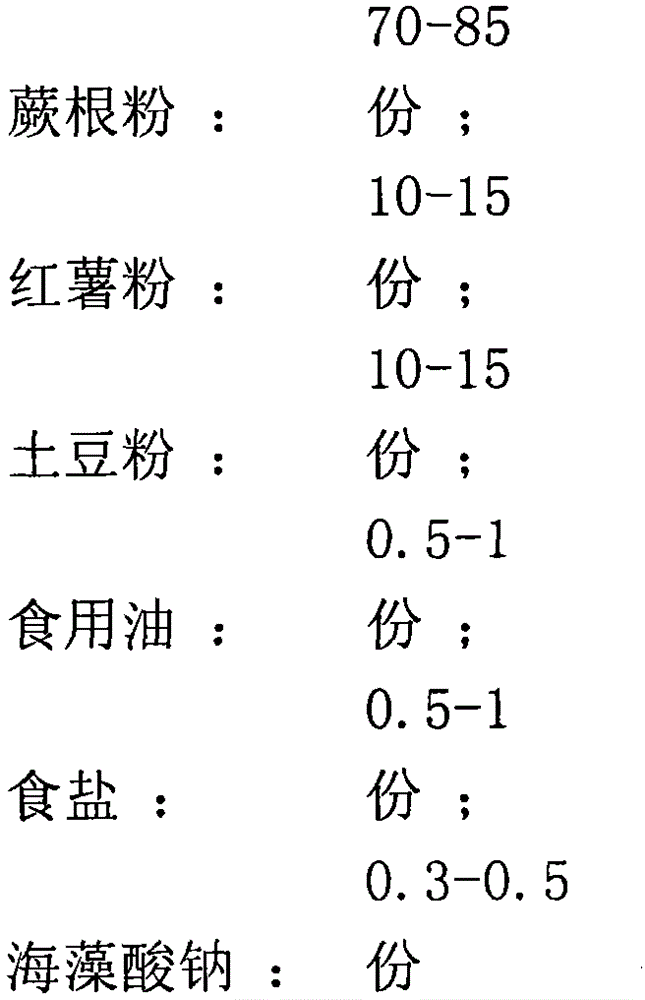

[0017] (2) Ingredients and thickening: put 70 parts of processed fern root powder, 10 parts of sweet potato powder, and 10 parts of potato powder into the noodle tank, add warm water at 50°C, stir with a smooth wooden stick, and add water from the side of the tank at the same time. 70°C hot water to make the powder temperature reach 45°C, stir rapidly, and then add boiling water to gelatinize the starch.

[0018] (3) Kneading the noodles: Put the crushed starch into the kneading tank and knead the noodles until no raw flour is seen, add 0.5 of edible oil, 0.5 of salt and 0.3 of sodium alginate according to the weight ratio, and continue kneading the noodles. The water content is about 48%. The surface temperature should always be kept above 40°C.

[0019] (4) Boiling water le...

Embodiment 2

[0023] (1), material selection and powder extraction: select fern root, sweet potato and potato with high starch content as raw materials, process and extract starch after cleaning for subsequent use.

[0024] (2) Ingredients and ginseng: Put 80 parts of fern root powder, 12 parts of sweet potato powder and 12 parts of potato powder into the noodle tank, add warm water at 50°C, stir with a smooth wooden stick, and add water from the side of the tank at the same time. 70°C hot water to make the powder temperature reach 45°C, stir rapidly, and then add boiling water to gelatinize the starch.

[0025] (3) Kneading the noodles: Put the crushed starch into the kneading tank and kneading the noodles until no raw flour is seen, add 0.7 edible oil, 0.7 salt and 0.3 sodium alginate according to the weight ratio, and continue kneading the noodles. The water content is about 48%. The surface temperature should always be kept above 40°C.

[0026] (4) Boiling water leakage: first add wat...

Embodiment 3

[0030] (1), material selection and powder extraction: select fern root, sweet potato and potato with high starch content as raw materials, process and extract starch after cleaning for subsequent use.

[0031] (2) Ingredients, beating: put 85 parts of fern root powder, 15 parts of sweet potato powder, and 15 parts of potato powder into the noodle tank, add warm water at 50°C, stir with a smooth wooden stick, and add water from the side of the tank at the same time. 70°C hot water to make the powder temperature reach 45°C, stir rapidly, and then add boiling water to gelatinize the starch.

[0032] (3) Kneading the dough: put the crushed starch into the kneading tank and knead the noodles in batches until no raw flour is seen, add 1 edible oil, 1 salt and 0.5 sodium alginate according to the weight ratio, and continue kneading the dough. The water content is about 48%. The surface temperature should always be kept above 40°C.

[0033] (4) Boiling water leakage: first add water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com