Dual-unit multi-group plaster application machine

A dual-unit, plastering machine technology, applied in the direction of making medicines into special physical or taking forms of devices, can solve the problems of traditional plaster, such as few clinical applications, uneven quality standards, and difficult quality control, and achieves The effect of low investment and production threshold, guaranteed quality standards and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

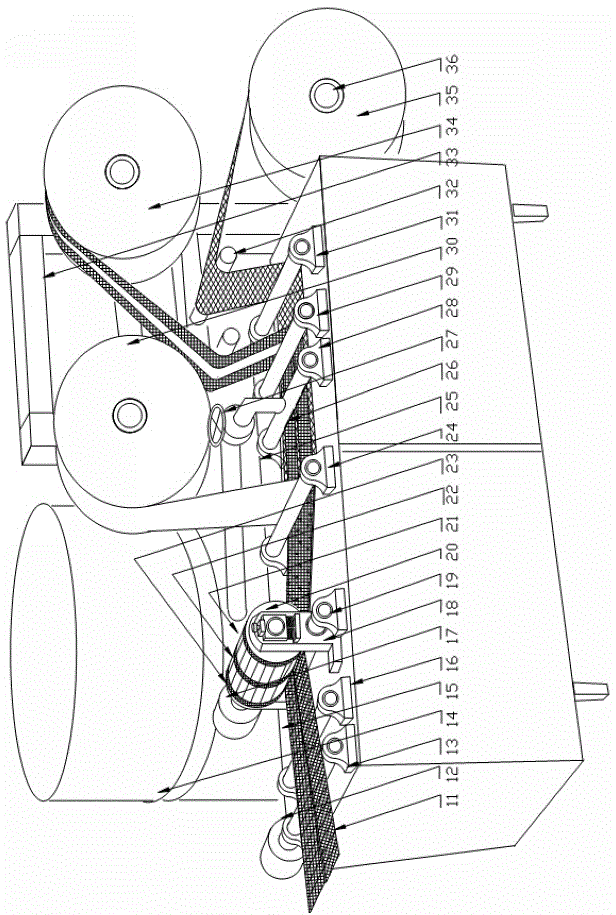

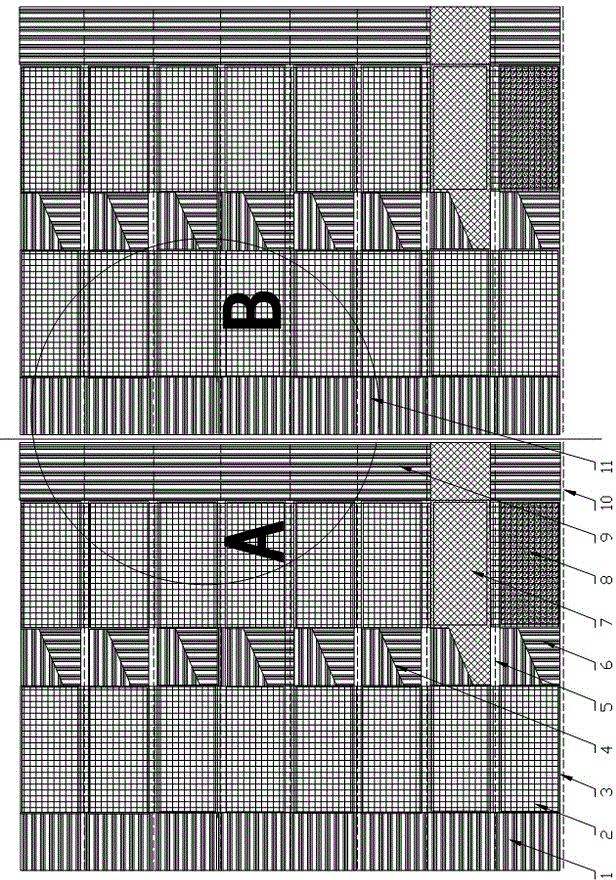

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] Such as figure 1As shown, the double-unit multi-group plastering machine includes double-unit multi-group plaster (11), drive roller motor (12), drive roller A (13), pressure plaster raw material tank (14), and drive chain A (15), drive roller B (16), pressure knife roller variable speed motor (17), pressure knife roller gantry (18), rubber roller (19), pressure knife roller pressure regulator (20), pressure knife roller (21 ), pressure cutting blade (22), traction bar (23), protective layer finishing roller (24), transmission chain B (25), plaster coating strip hole (26), plaster coating adjustment switch (27), plaster Applicator (28), plaster bearing layer finishing roller (29), protective layer roll material (30), plaster surface layer finishing roller (31), auxiliary finishing roller (32), roll material mounting frame (33) , Loading layer reel material (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com