Pressure and temperature precisely controllable hot pressing molding device for friction material

A friction material, hot-press forming technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of low processing noise, insufficient equipment accuracy, inability to realize pressure and temperature feedback control, etc., to ensure quality, improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

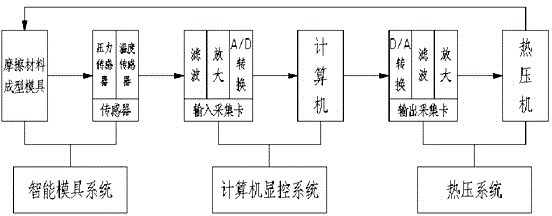

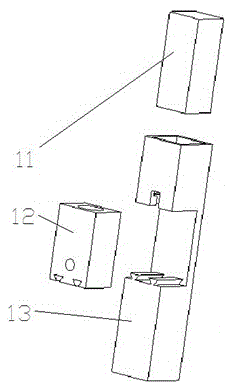

[0016] Such as Figure 1 to Figure 3 As shown, the friction material hot press molding device with precise and controllable pressure and temperature includes a hot pressing system, a computer display control system and an intelligent mold system. The computer display control system includes an input acquisition card and a computer; the hot press system includes an output acquisition card and heat press 5;

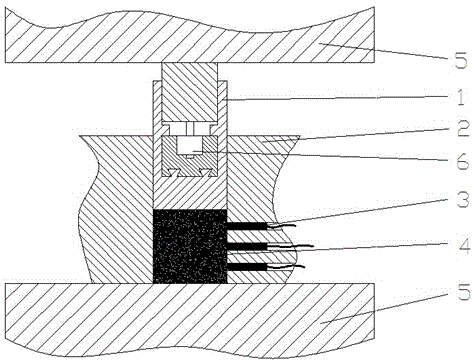

[0017] The intelligent mold system includes a pressing body 1, a mold 2 and a sensor; a through hole is opened from the outer surface of the mold 2 to the inner wall of the mold cavity, and the sensor is set in the through hole, where the sensor is a temperature sensor 3, and the setting position is in the through hole close to the mold cavity The position of the inner wall, so that the measured temperature value can completely represent the temperature of the measured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com