Heavy-load low-structure-complexity double-coaxial-twin-rotor unmanned aerial vehicle

A technology of coaxial dual-rotors and unmanned aerial vehicles, which is applied in the direction of aircraft, rotorcraft, propellers, etc., can solve the problems of payload and ease of control that are difficult to meet user needs, high R&D costs, and difficult design, etc., to achieve independent Effective load space, simple structure, and improved flight stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] specific implementation plan

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

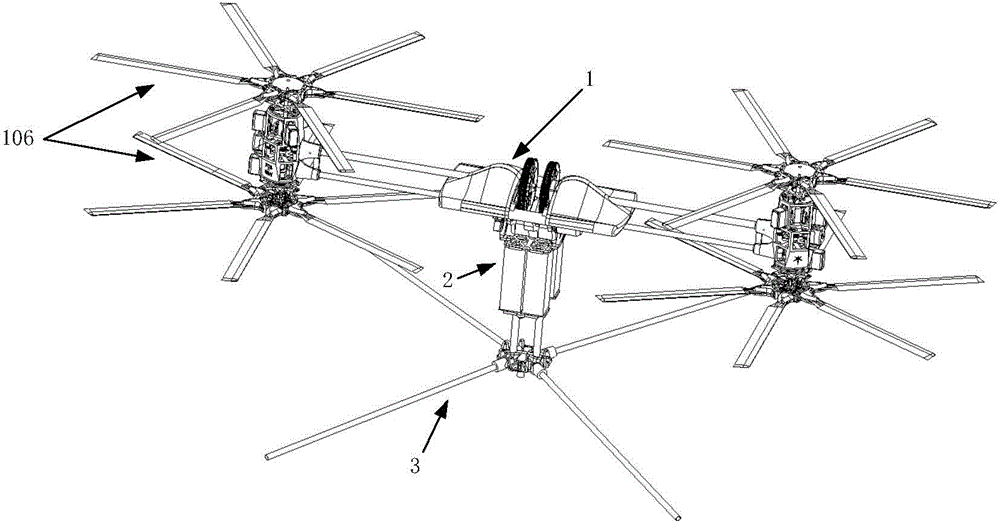

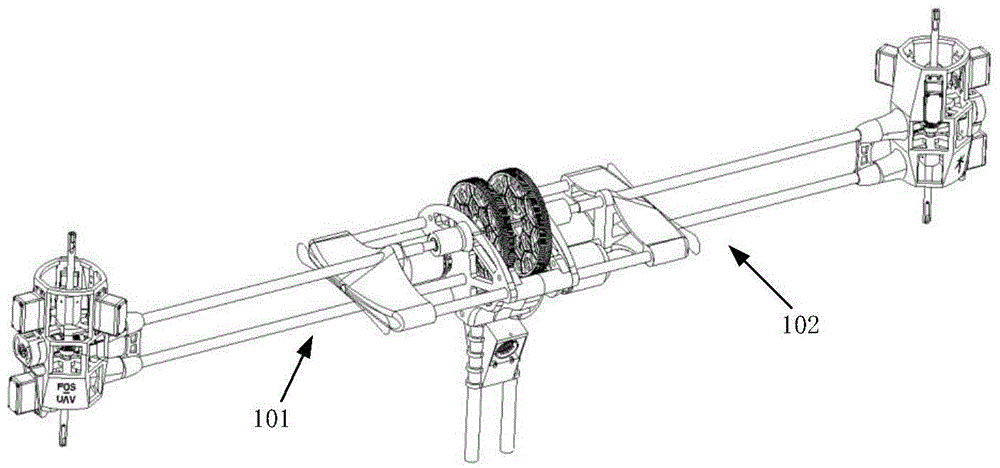

[0037] The dual-coaxial dual-rotor UAV with large load and low structural complexity of the present invention includes a body 1 , a control system 2 and a landing gear 3 ; and the body 1 includes a left half body 101 and a right half body 102 . The left half body 101 has the same structure as the right half body 102, both including a fuselage 103, a gear drive mechanism 104, a rotor drive mechanism 105, a coaxial double rotor 106, a full pitch variable mechanism 107, and a collective pitch variable mechanism 108, Such as figure 1 , figure 2 , image 3 shown.

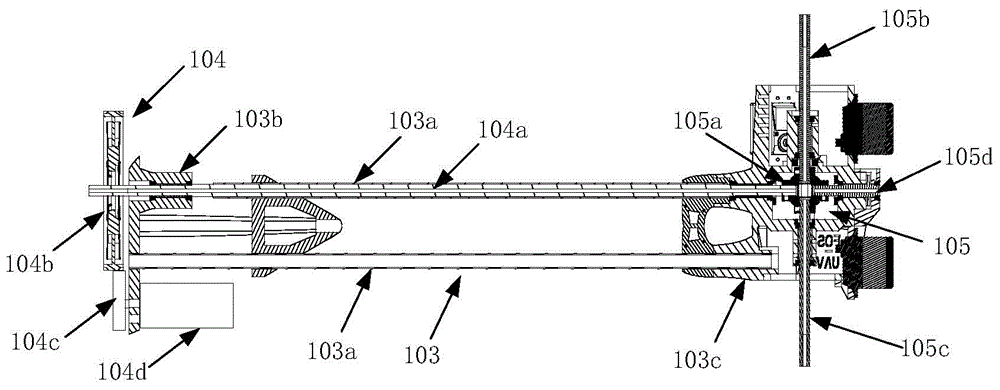

[0038] The fuselage 103 includes a support rod 103a, a main support frame 103b, a transmission shaft 103c, and a rotor cabin 103c; the support rod 103a is two, and is arranged horizontally up and down; the left ends of the two support rods 103a are tightly fitted with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com