Supercell structure directly developed nano-grade beta-Li2TiO3 powder supercritical preparation method

A nano-scale, supercritical technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of long preparation cycle, destruction of supercellular structure, complicated operation, etc., and achieve preparation cycle time. Short, lower activation barrier, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A Nanoscale β-Li Directly Developed by a Supercellular Structure 2 TiO 3 The supercritical preparation method of powder comprises the following steps:

[0045] 1) Weigh TiO according to the molar ratio of Li:Ti (1.85~2.25):1 2 powder and LiOH·H 2 O powder, put the two into the high-pressure container (the material is Hastelloy, the pressure range is 50-200MPa), and then add distilled water to the high-pressure container according to the volume ratio of distilled water accounting for 20%-80% of the volume of the high-pressure container, and mix Uniform, and control Li + The concentration is 0.1~2mol / L;

[0046] 2) Put the high-pressure container in a high-temperature drying oven, and react at 375-450°C for 5-20 hours;

[0047] 3) Place the high-pressure container in an oven, and dry at 50-80°C for 8-12 hours to obtain β-Li 2 TiO 3 Powder;

[0048] 4) the β-Li obtained in step 3) 2 TiO 3 The powder is ground evenly to obtain nano-sized β-Li 2 TiO 3 Powder.

Embodiment 1

[0051] 1) Weigh TiO according to the molar ratio of Li:Ti of 1.90:1 2 powder and LiOH·H 2 O powder, add the two into a high-pressure vessel (the material is Hastelloy, and the pressure range is 50-200MPa), then add distilled water to the high-pressure vessel according to the volume ratio that distilled water accounts for 50% of the volume of the high-pressure vessel, mix evenly, and Control Li + The concentration is 1mol / L;

[0052] 2) Put the high-pressure container in a high-temperature drying oven and react at 400°C for 10 hours;

[0053] 3) Put the high-pressure container in an oven and dry at 80°C for 10 hours to obtain β-Li 2 TiO 3 Powder;

[0054] 4) the β-Li obtained in step 3) 2 TiO 3 The powder is ground evenly to obtain nano-sized β-Li 2 TiO 3 Powder.

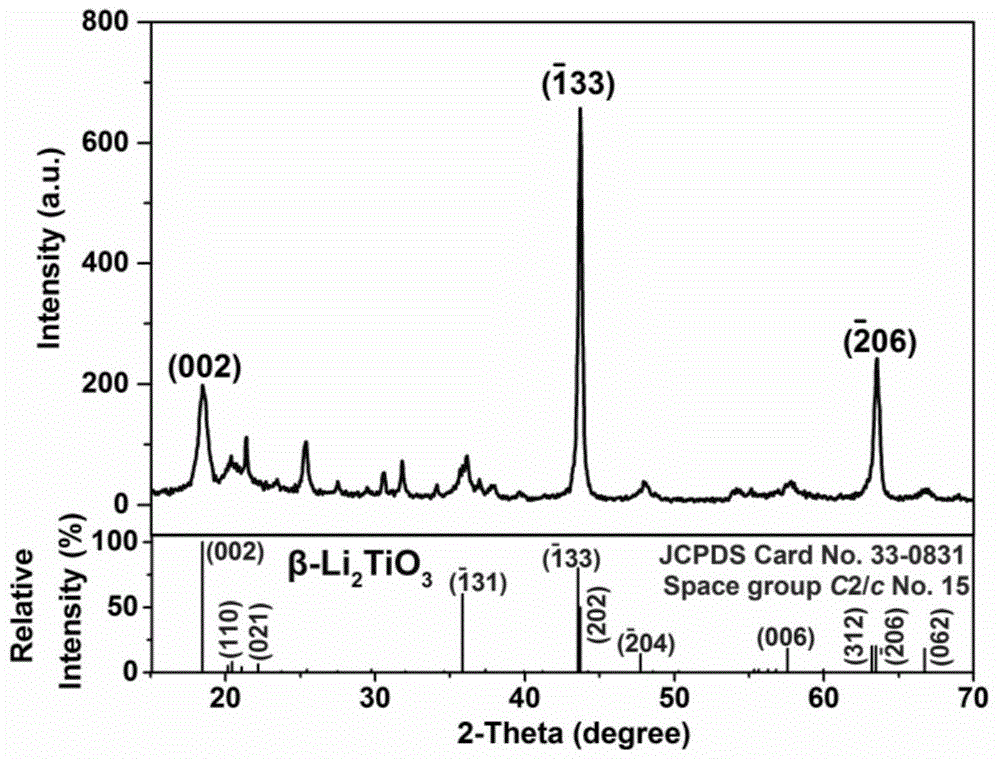

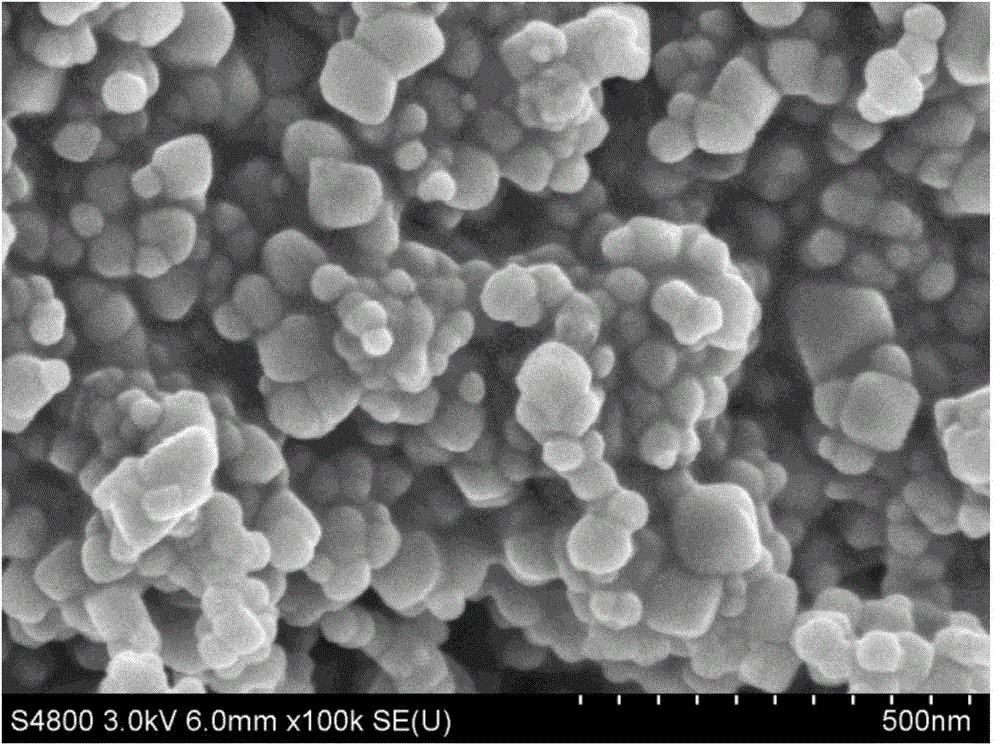

[0055] figure 1 It is the nanoscale β-Li prepared in this embodiment 2 TiO 3 The XRD pattern of the powder shows that supercells have begun to develop, The value is 0.22.

Embodiment 2

[0057] 1) Weigh TiO according to the molar ratio of Li:Ti of 2.15:1 2 powder and LiOH·H 2 O powder, add the two into a high-pressure vessel (the material is Hastelloy, and the pressure range is 50-200MPa), then add distilled water to the high-pressure vessel according to the volume ratio that distilled water accounts for 40% of the volume of the high-pressure vessel, mix evenly, and Control Li + The concentration is 0.5mol / L;

[0058] 2) Place the high-pressure container in a high-temperature drying oven and react at 380°C for 10 hours;

[0059] 3) Place the high-pressure container in an oven and dry at 70°C for 12 hours to obtain β-Li 2 TiO 3 Powder;

[0060] 4) the β-Li obtained in step 3) 2 TiO 3 The powder is ground evenly to obtain nano-sized β-Li 2 TiO 3 Powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com