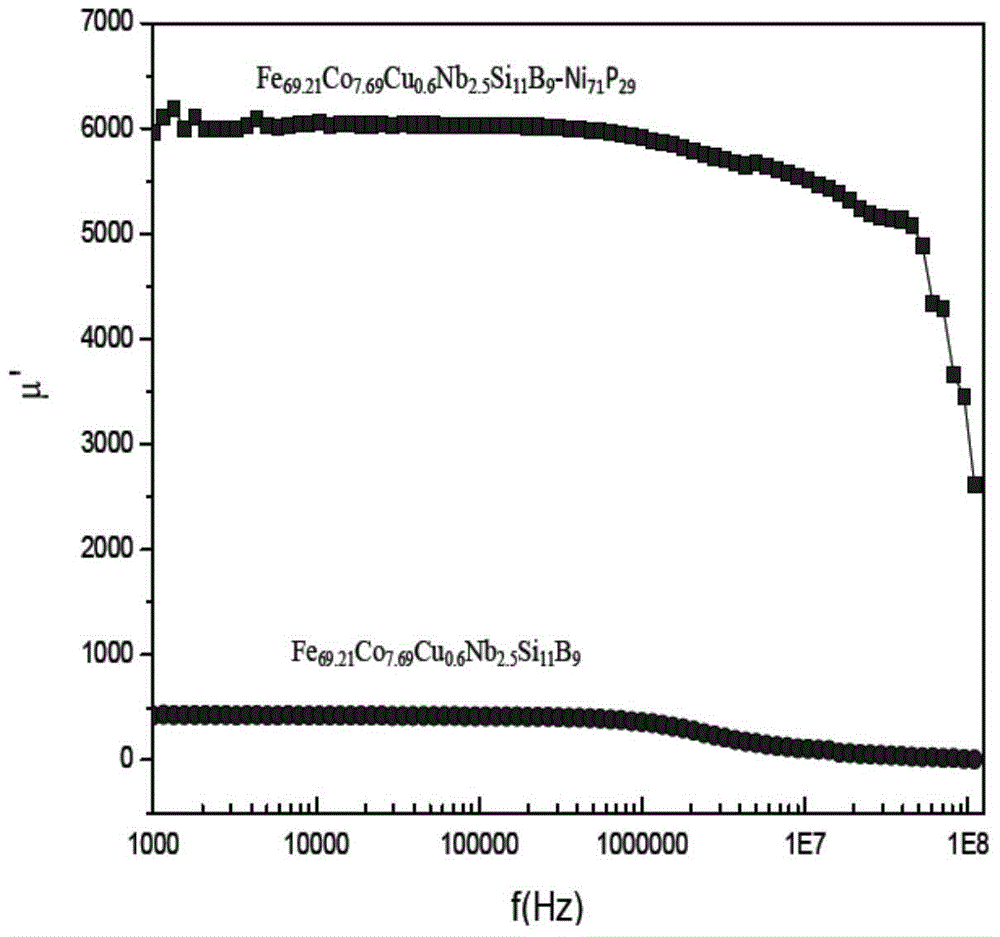

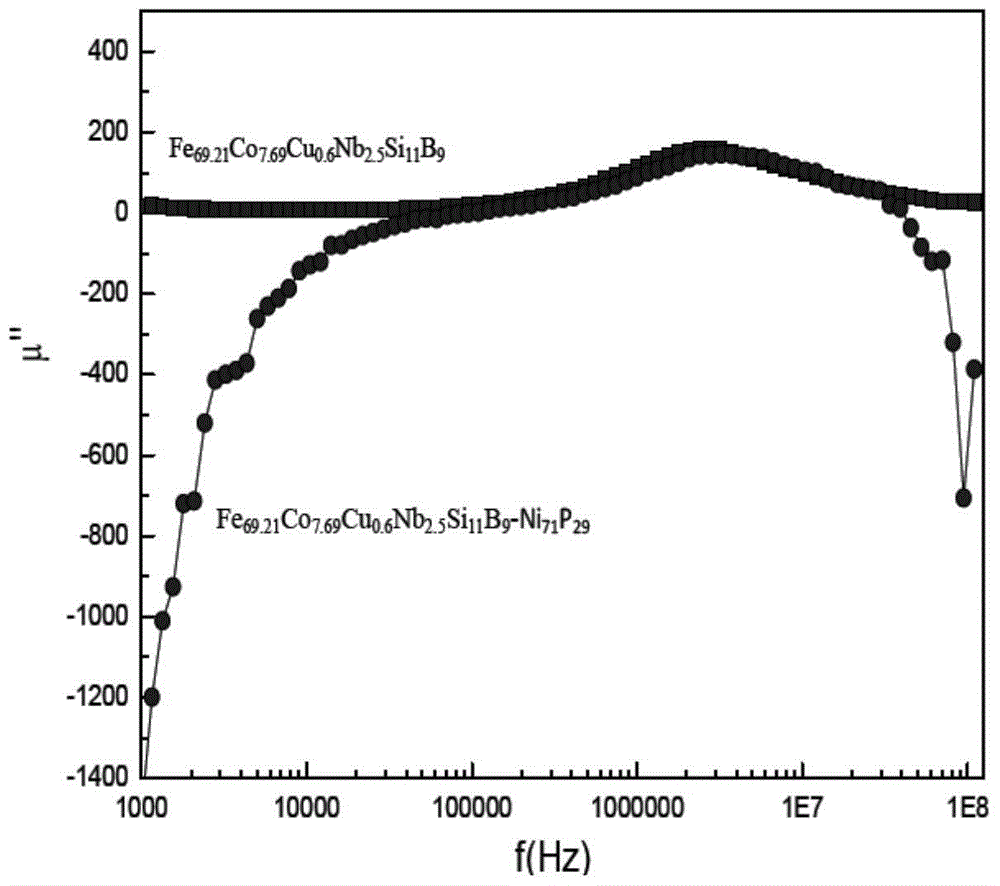

Composite amorphous magnetically soft alloy having high initial permeability and high quality factor

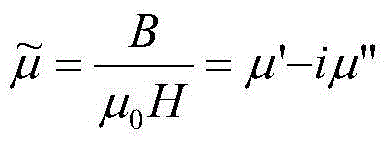

A technology with initial magnetic permeability and high quality factor, which is applied in the direction of magnetic materials, magnetic objects, metal material coating technology, etc., to achieve the effect of low cost, superior high frequency performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] A method for preparing a composite amorphous soft magnetic alloy with high initial permeability and high quality factor, the chemical formula of the composite amorphous soft magnetic alloy is Fe 69.21 co 7.69 Cu 0.6 Nb 2.5 Si 11 B 9 -Ni 71 P 29 , prepared by chemical deposition method, the steps are as follows:

[0031] 1) Fe 69.21 co 7.69 Cu 0.6 Nb 2.5 Si 11 B 9 Preparation of master alloy ingot

[0032] Fe, Co, Cu, Nb, Si, and B raw materials with a purity of 99.95% were selected, and ingredients were prepared according to the mass percentage of the elements, and smelted into a master alloy ingot in a vacuum induction furnace with a weight loss of 4%;

[0033] 2) Fe 69.21 co 7.69 Cu 0.6 Nb 2.5 Si 11 B 9 Preparation of Amorphous Soft Magnetic Alloy Ribbon

[0034] The above-mentioned master alloy ingot is put into the quick quenching equipment by the single-roller melt rotation quick quenching method. After remelting, the master alloy ingot is quick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com