Masking plate assembly, display device and manufacturing method

A manufacturing method and mask technology, which can be applied to devices for coating liquid on the surface, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems affecting mask bonding, uneven mask surface, and shadows. effect and other issues to achieve the effect of improving the display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

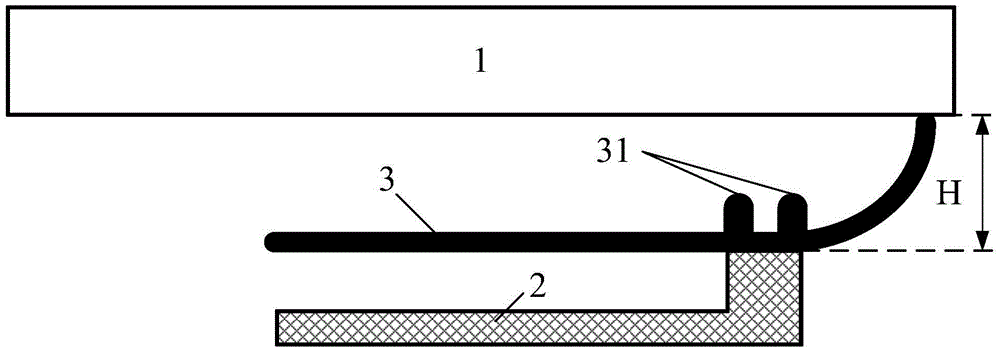

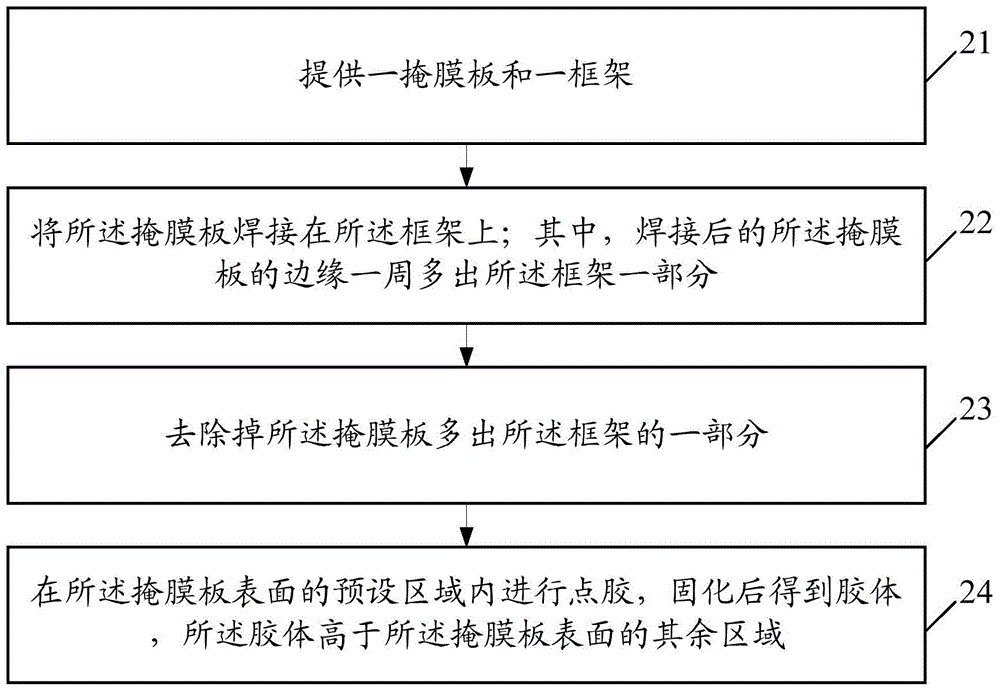

[0029] In order to avoid the phenomenon of unevenness on the surface of the mask plate, the embodiment of the present invention provides a new manufacturing method of the mask plate assembly, such as figure 2 shown, including:

[0030] Step 21, providing a mask plate and a frame;

[0031] Step 22, welding the mask plate on the frame; wherein, the welded mask plate has redundant parts beyond the frame;

[0032] Step 23, removing at least a part of the redundant parts;

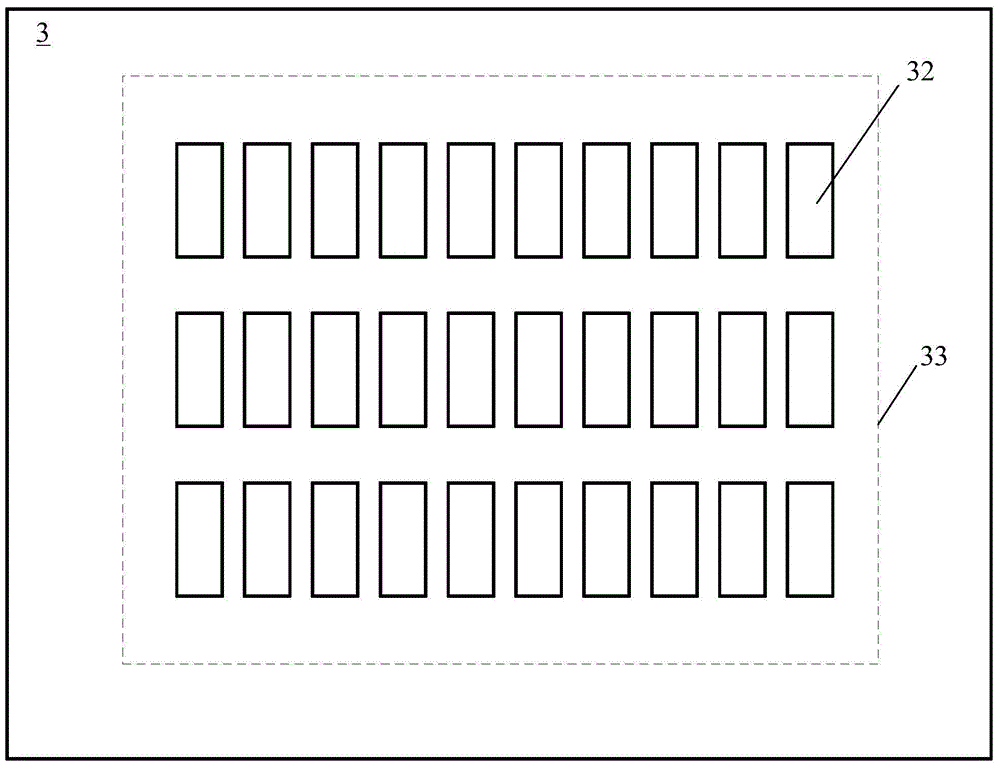

[0033] Step 24, dispensing glue in a preset area on the surface of the mask, and obtaining a colloid after curing, the colloid being higher than the remaining areas on the surface of the mask.

[0034] In the manufacturing method of this embodiment, the mask plate is indirectly bonded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com