Full-loose, continuous dyeing and whitening production line and its fabric whitening or color-fixing finishing production process

A production process and production line technology, applied in the field of dyeing and finishing production equipment and its production process, can solve the problems of low production efficiency, large amount of waste water and long cycle, and achieve low production cost, small amount of waste water and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

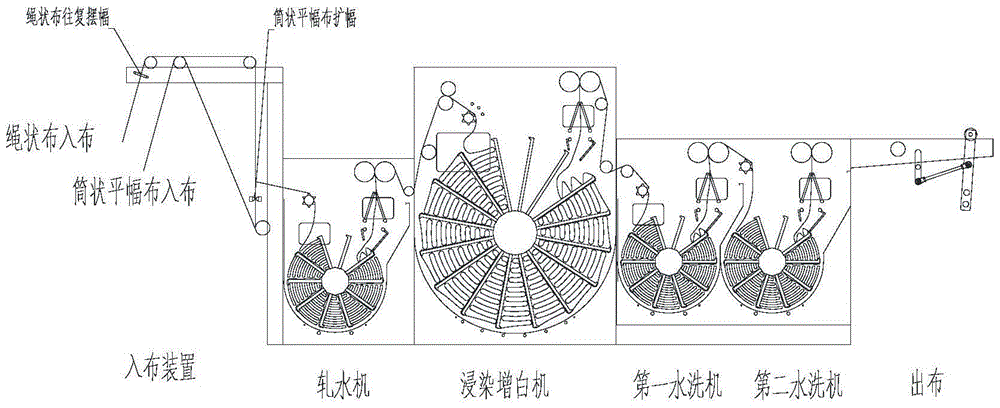

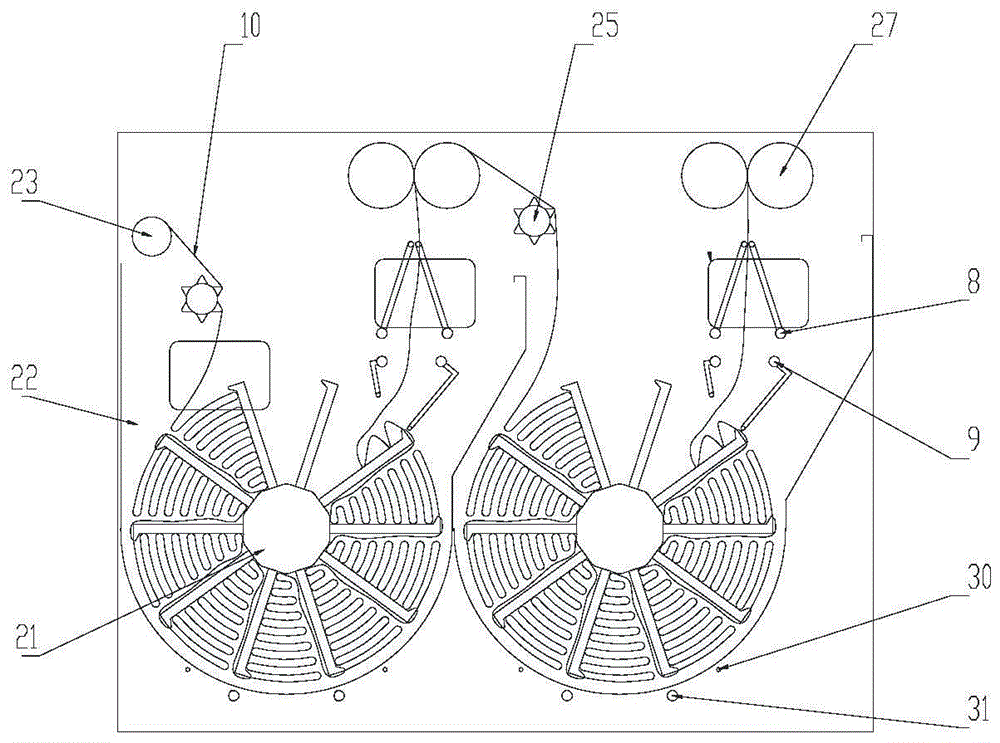

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the full-loose type, continuous dip dyeing and whitening production line of the present invention is characterized in that the host equipment includes a water squeezer, a dip dyeing and whitening machine, a first washing machine and a second washing machine arranged in sequence along the straight line direction, in:

[0056] The above-mentioned water padding machine is used for padding the fabric to be dyed and finished, so that the fibers of the fabric are fully wetted and expanded, and the moisture content of the fabric is controlled.

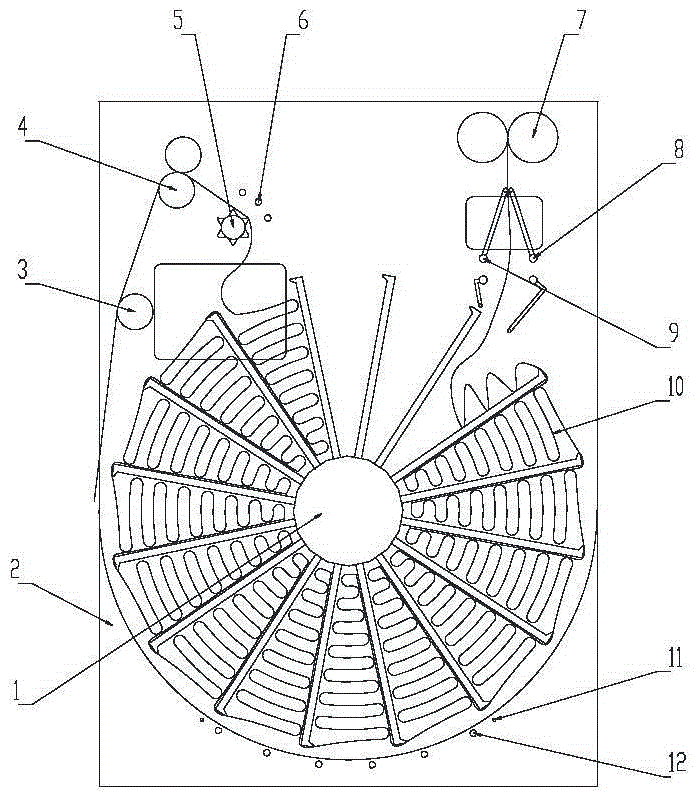

[0057] The above-mentioned dyeing and whitening machine includes a first drum 2 with a first impeller 1, and a cloth inlet and a cloth outlet are respectively arranged on the left and right sides of the first drum, and a cloth inlet is provided at the position of the cloth inlet. The first guiding device a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com