An evaluation test device for corrosion inhibitor film layer of gathering and transportation pipeline

A technology of evaluation test and corrosion inhibitor film, which is applied in the field of anti-corrosion in sour natural gas gathering and transportation pipelines, which can solve the problems such as the inability to dynamically and accurately evaluate the performance, and achieve the effect of reducing the cost of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

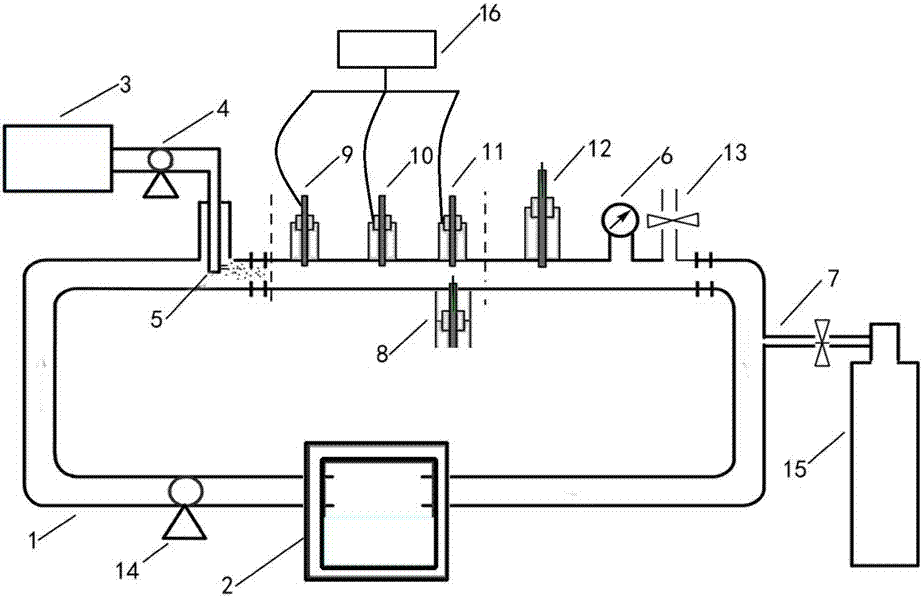

[0015] A corrosion inhibitor film evaluation test device for gathering and transportation pipelines, including a loop pipeline 1 made of 316L stainless steel or nickel-based alloy material, an autoclave 2 and a gas circulation pump 14 are arranged on the lower pipeline of the loop pipeline 1, and the high-pressure The autoclave 2 provides high-pressure steam for the loop pipeline 1 to simulate the moisture environment in the pipeline. The gas circulation pump 14 is located on the left side of the autoclave 2, and the gas circulation pump 14 provides a circulating air flow for the loop.

[0016] A number of holes are opened on the upper pipe of the loop pipe 1, and the resistance probe 9, the electrochemical probe 10, the weight loss sample 11, the temperature and humidity meter 12, the pressure gauge 6 and the sampler 13 are placed in the holes in sequence, and the loop pipe 1 A hole is opened below the upper pipeline corresponding to the weightless sample 11, and a thickness m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com