Stress-torsion magnetic impedance integration test device of metal fiber

A metal fiber, comprehensive testing technology, applied in the direction of magnetic performance measurement, etc., can solve the problem that impedance measurement cannot be directly and effectively achieved, and achieve the effect of easy replacement, less fiber breakage and kink, and improved test accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

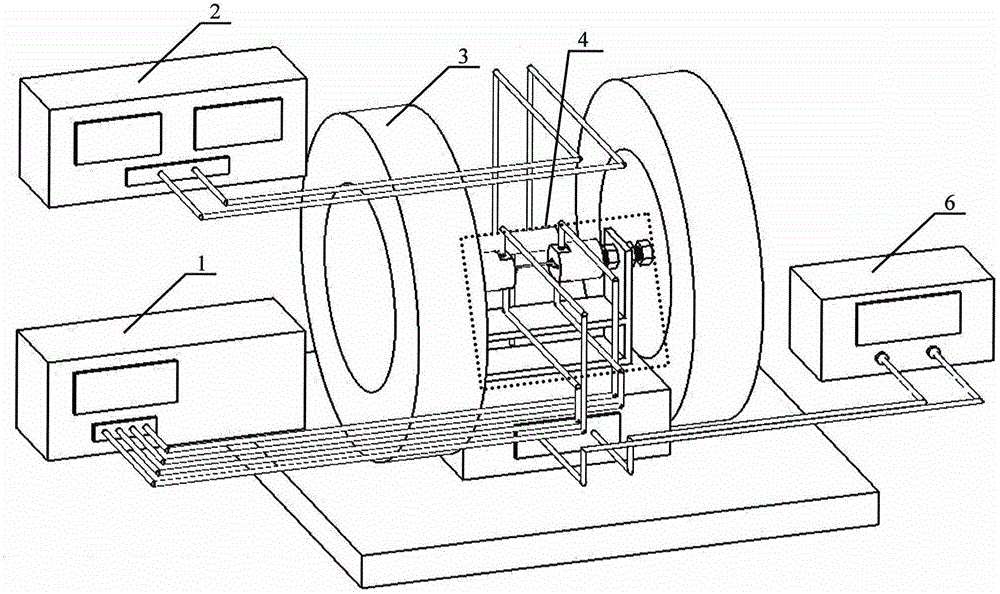

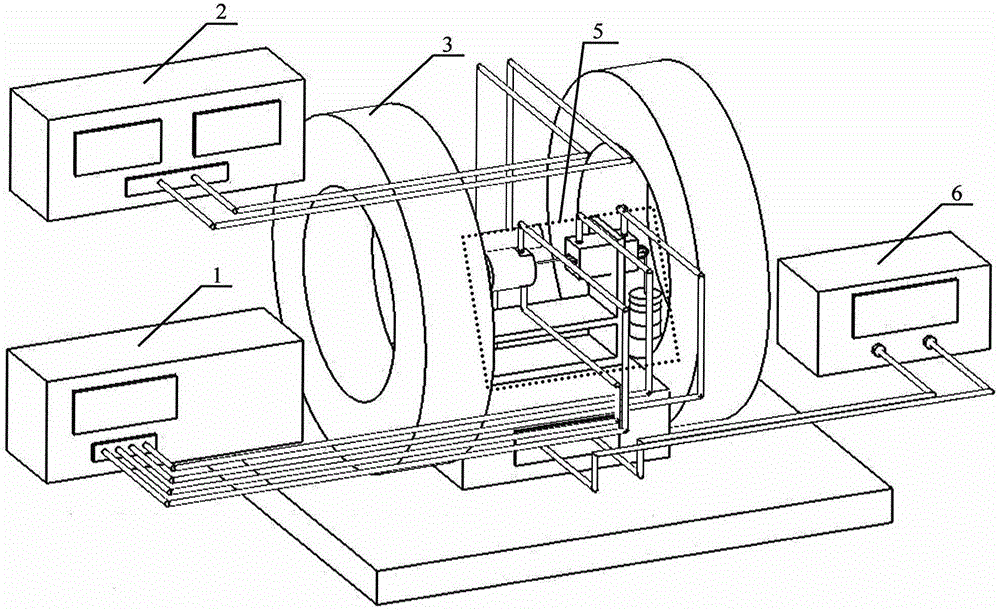

[0029] Embodiment one: if figure 1 As shown, the stress-torsion magnetic impedance comprehensive testing device of the metal fiber of the present invention comprises a comprehensive testing platform and an attached magnetic field generating device, and the comprehensive testing platform is connected with four terminals for collecting the impedance of the metal fiber to be measured in the platform. Magnetic impedance test and analysis system and magnetic field correction and monitoring system; the magnetic field generating device includes a Helmholtz coil 3 and a DC power supply 6 connected thereto; Stress torsion platform 4; said four-terminal magneto-impedance test and analysis system includes an impedance analyzer 1; said magnetic field correction and monitoring system includes a fluxgate uniaxial magnetometer 2 and its sensor set on one side of said stress-free torsion platform 4 probe, and the axis of the probe is parallel to the axis of the Helmholtz coil 3, and its axis ...

Embodiment 2

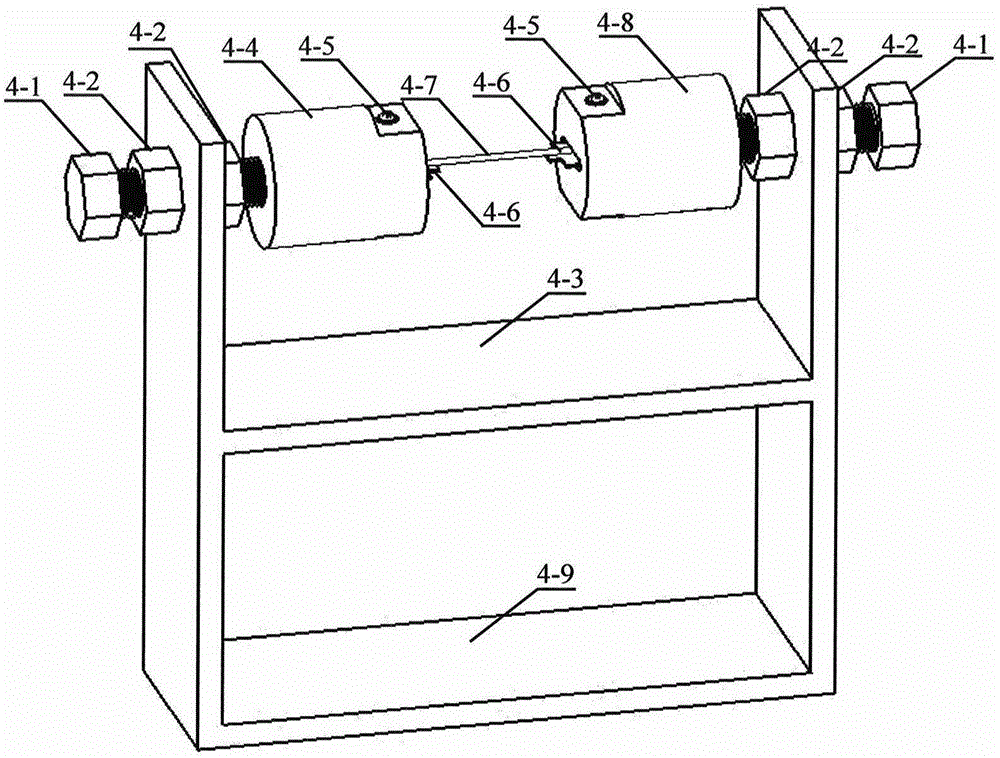

[0033] Embodiment two: if figure 2 As shown, the present embodiment is a further limitation on the implementation of the stress-free torsional magnetic impedance comprehensive test device, and the further limitation is: the stress-free torsion platform 4 is the left and right relative upper outriggers of the bakelite skeleton. The left horizontal wire shaft and the right horizontal wire shaft on the same axis are slidingly matched in the circumferential direction; the outer end of the left horizontal wire shaft passing through the left upper outrigger is fixedly fitted with a rotating nut 4-1, and the inner end is fixedly fitted with a left aluminum alloy The rotating body 4-4, the inner and outer fastening nuts 4-2 located on the inner and outer sides of the left upper outrigger fasten the left horizontal wire shaft; Nut 4-1, the inner end is fixedly matched with the right aluminum alloy rotating body 4-8, and the inner and outer fastening nuts 4-2 located on the inner and o...

Embodiment 3

[0036] Embodiment 3: This embodiment is a further limitation of the stress-torsion magnetic impedance comprehensive test device for the metal fiber described in Embodiment 1. The torsion range parameter applied by the stress-free torsion platform is: 0-6667 2π rad / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com