Method for preventing thin film at edge of silicon chip from being peeled off

A thin-film stripping and silicon nitride thin-film technology, applied in electrical components, electrical solid-state devices, semiconductor/solid-state device manufacturing, etc., can solve problems such as brittleness and stripping, eliminate potential risks, and solve the problem of thin film stripping at the edge of silicon wafers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical solutions and advantages of the present invention more comprehensible, further details will be described below in conjunction with the accompanying drawings. It should be noted that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

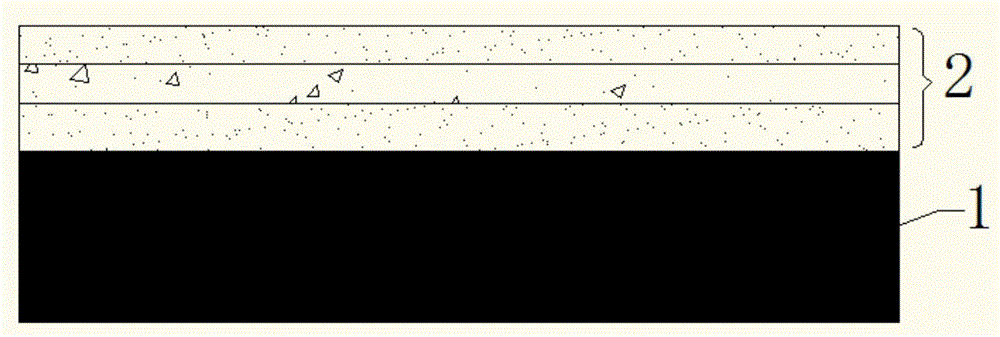

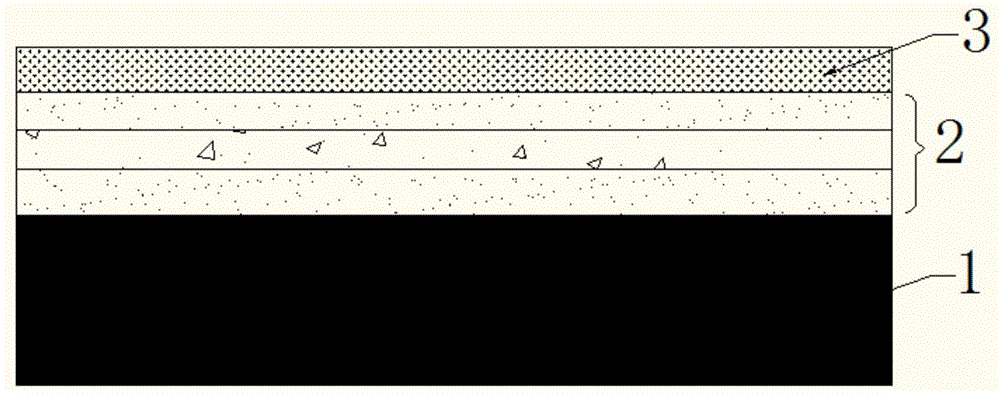

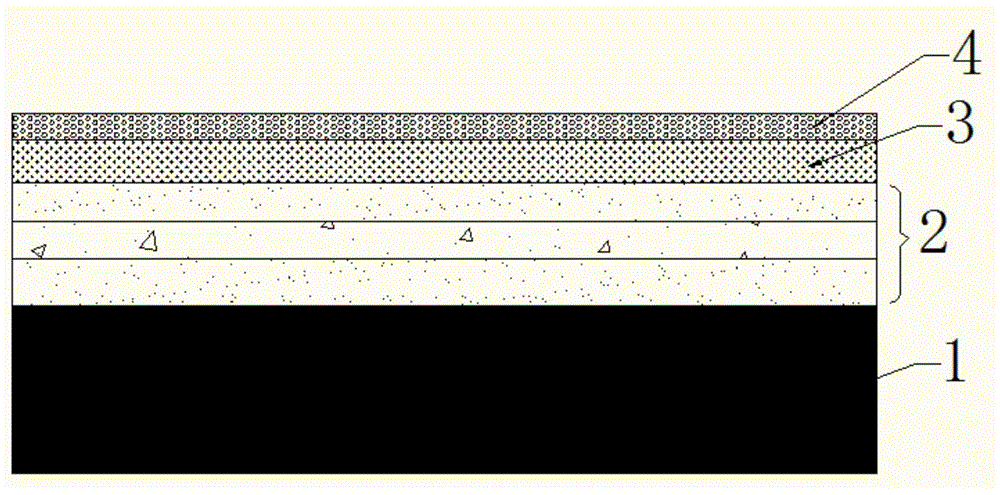

[0025] The core idea of the present invention is: when using the existing process flow, due to the large degree of warpage of the silicon wafer, in the process of depositing the amorphous carbon film, due to the brittle nature of the film, it is easy to be damaged during the cooling process of the silicon wafer. The phenomenon that the edge of the silicon wafer is peeled off. And adopt the method of the present invention, before depositing the amorphous carbon film, pre-deposited one deck and the thin film of silicon wafer warpage degree in advance, thereby reduced the total warpage degree of silicon wafer, when it carries out amorphou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com