Member for nuclear reactors

A technology for nuclear reactors and components, used in reactors, nuclear engineering, nuclear power generation, etc., can solve problems such as hindering the structure and function of graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

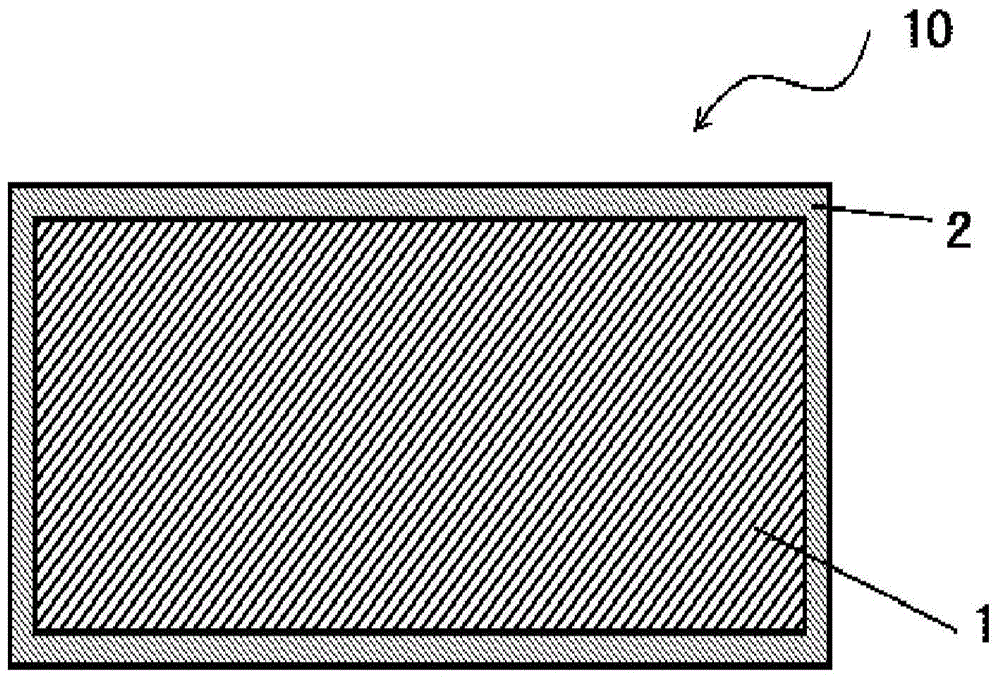

[0052] Embodiment 1 of the present invention will be described below. figure 1 is a cross-sectional view of a nuclear reactor component according to Example 1 of the present invention. Example 1 has a structure in which the surface of a pellet-shaped core portion is covered with a silicon carbide (SiC) covering layer.

[0053]

[0054] Graphite powder (which is graphite particles with a weight of 3.1 g and a 50% volume particle diameter of 3.65 μm) was filled into a mold with pores of φ25 mm and pressurized at a pressure of 19 MPa. The core part molded from graphite powder is removed from the mold. A flat plate-shaped core portion of φ25×6 mm is formed, which is brittle and easily broken.

[0055] The graphite powder was obtained by coarsely pulverizing an isotropic graphite material ET-10 (manufactured by Ibiden Co., Ltd.), followed by pulverization with a jet mill.

[0056] The apparent density of the core part is 1.05 g cm -3 .

[0057]

[0058] The core portion ob...

Embodiment 2

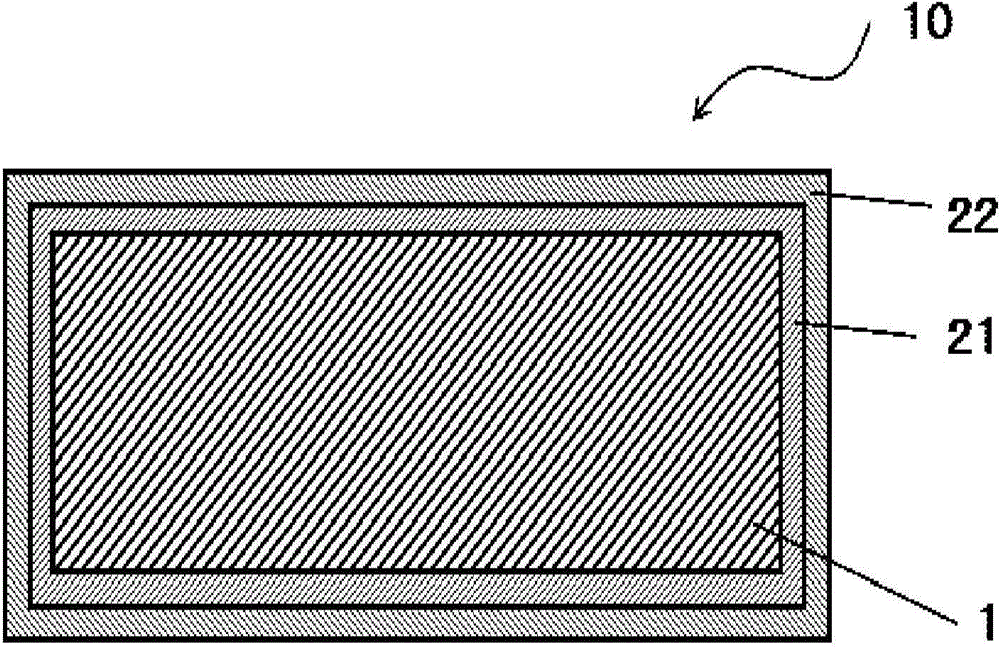

[0062] Embodiment 2 of the present invention is described below. figure 2 It is a cross-sectional view of a nuclear reactor component according to Example 2 of the present invention. Example 2 has a structure in which the surface of a pellet-shaped core portion is covered with a pyrolytic carbon coating and further covered with a silicon carbide (SiC) coating.

[0063]

[0064] Graphite powder (which is graphite particles with a weight of 3.1 g and a 50% volume particle diameter of 3.65 μm) was filled into a mold with pores of φ25 mm and pressurized at a pressure of 19 MPa. The core part molded from graphite powder is removed from the mold. A flat plate-shaped core portion of φ25×6 mm is formed, which is brittle and easily broken.

[0065] The graphite powder was obtained by coarsely pulverizing an isotropic graphite material ET-10 (manufactured by Ibiden Co., Ltd.), followed by pulverization with a jet mill.

[0066] The apparent density of the core part is 1.05 g cm -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com