Friction damping guide head

A friction damping, guide head technology, applied in boring heads, tool holder accessories, metal processing equipment, etc., can solve the problem that the boring head cannot perform radial feed, cannot perform inner hole boring, and has weak boring flexibility. and other problems, to achieve the effect of improving processing practicability, small structure, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

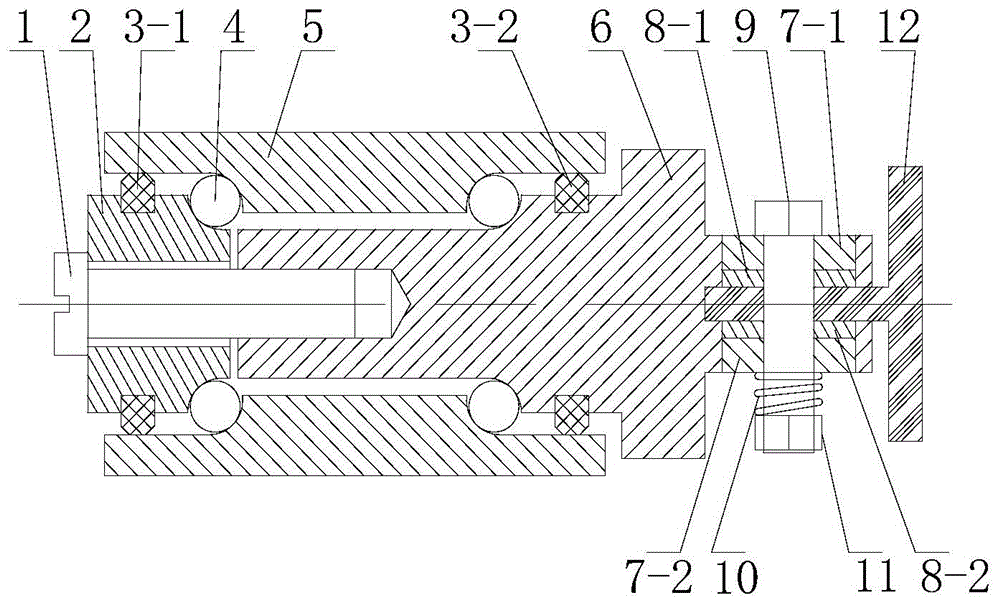

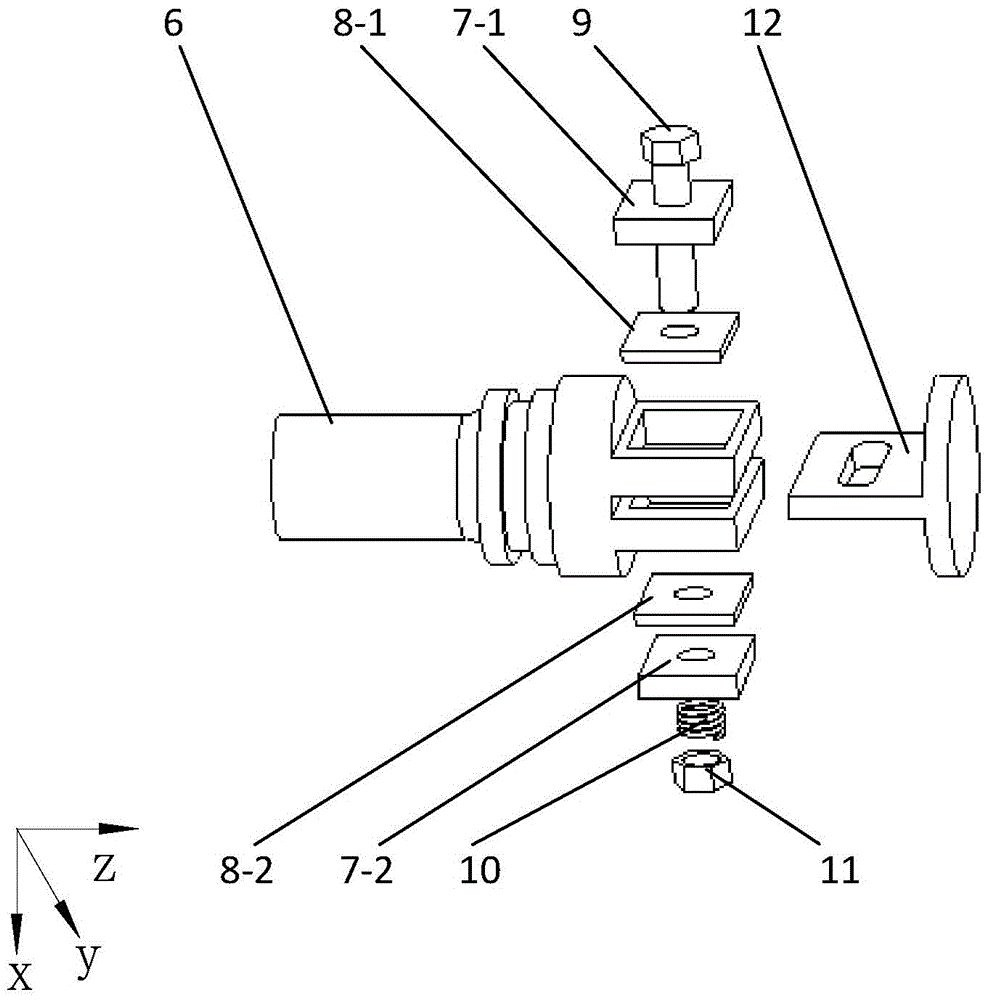

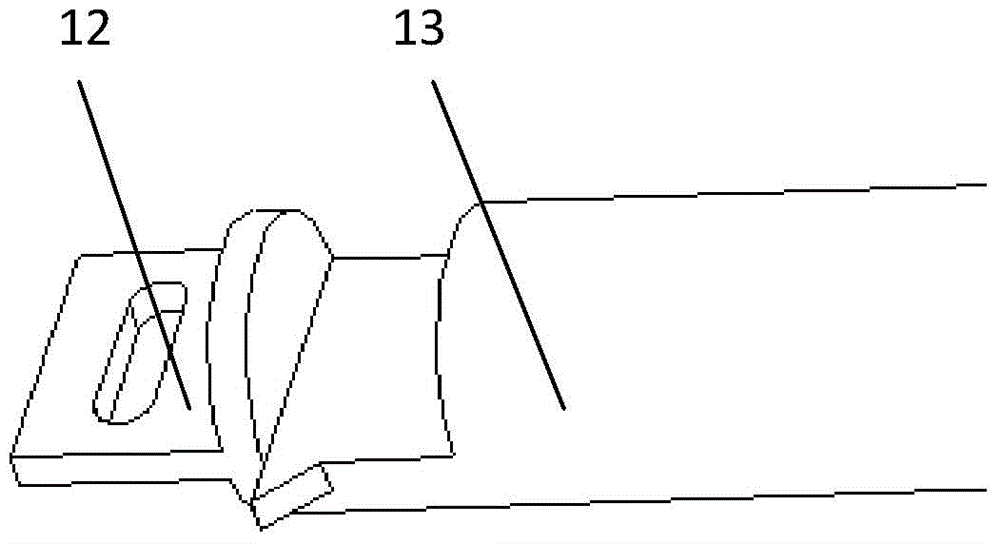

[0033] Such as figure 1 It is a schematic diagram of the overall structure of the friction damping guide head of the present invention, which is mainly suitable for processing deep and long holes with relatively large length and diameter. The friction damping guide head is mainly composed of a guide part and a friction damping part. The guide part can provide a support for the boring bar to prevent the boring bar from being deformed by force. The friction damping part increases the damping of the boring bar system and reduces the resonance of the boring bar. amplitude.

[0034]The guide part is mainly composed of a guide jacket 5, an outer stopper 2, a guide shaft 6, a fastening screw 1, a ball 4, a first elastic seal 3-1 and a second elastic seal 3-2. The guide jacket 5 is set on the outside of the journal of the guide shaft 6, and the ball 4 is rotated on the journal end of the guide shaft 6. The gap between the guide jacket 5 and the journal end of the guide shaft 6 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com