Turnover type overhauling platform

An overhaul platform, flip-up technology, applied in ship parts, ships, transportation and packaging, etc., can solve problems such as loss of 2# side pusher and telescopic pusher, inconvenient maintenance of oil tanks, blocking of escape channels, etc., and achieve great promotion value. , easy to operate, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take the maintenance platform at the top of the escape passage of the 2# side thruster cabin with a clearance of 1m*1m as an example below to illustrate the overturning maintenance platform of the present invention. The content not mentioned in this embodiment is the same as the general situation above.

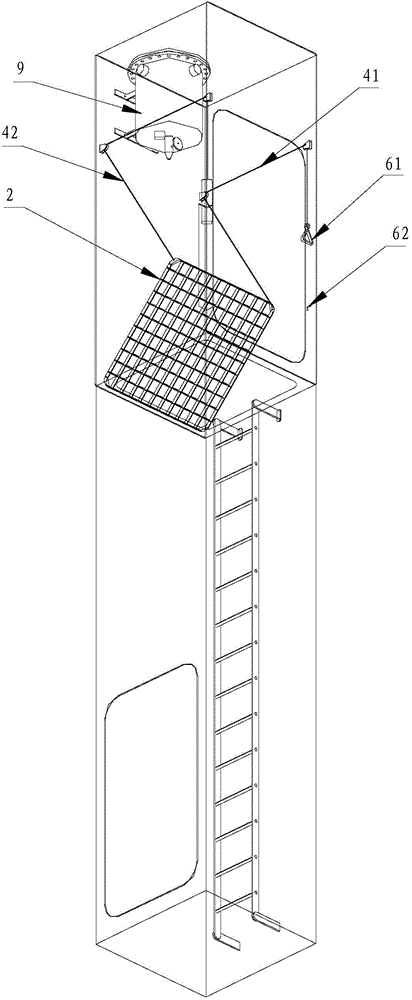

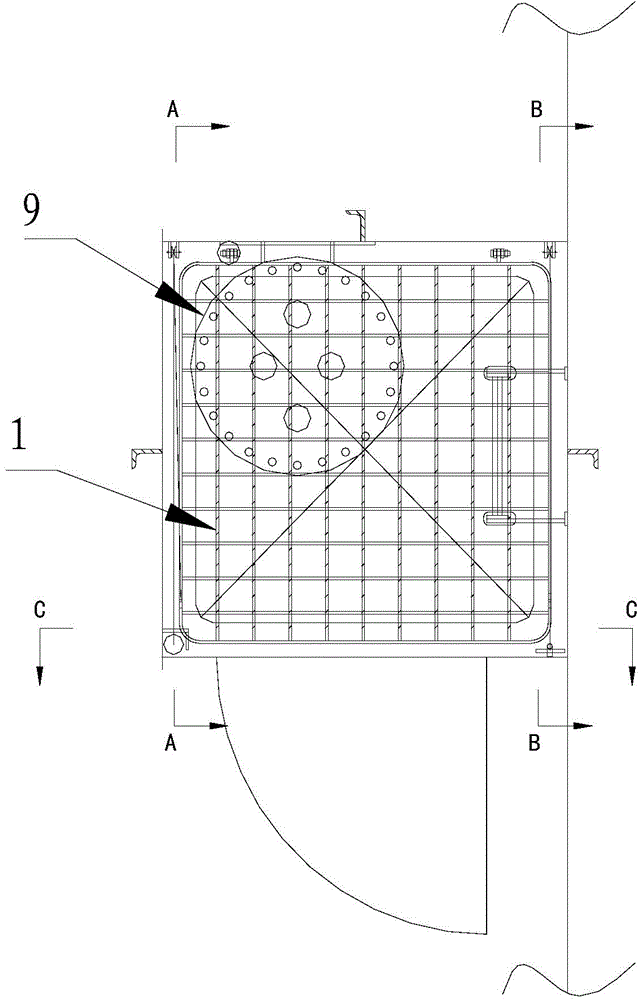

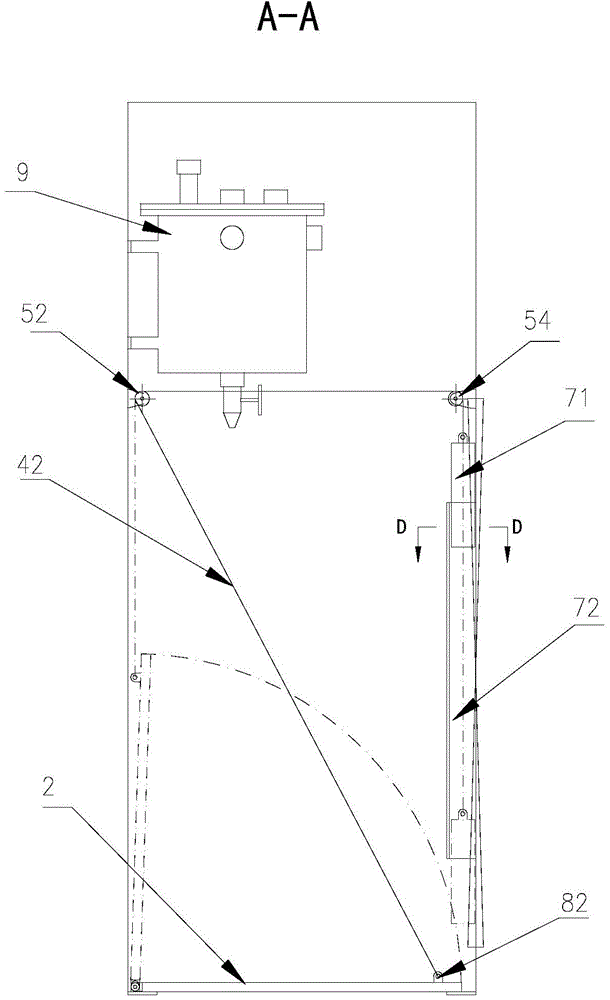

[0044] Such as Figure 1-6 As shown, a reversible maintenance platform 1 includes a grid 2 , a first lifting structure 31 and a second lifting structure 32 .

[0045] Such as Figure 7-8 As shown, the grille 2 is rectangular, and its size is designed to be 1.1m×1.1m according to the size of the escape passage, and it is manufactured according to the CB / T608-1998 standard. The side of the grid 2 that is hinged with the hull wall (the side where the hinge is located) is called the hinged side, the opposite side that can be flipped along the hinged side is called the flipped side, and the side adjacent to the hinged side and the flipped side is called the side edge. Th...

Embodiment 2

[0057] The overturning maintenance platform of the present invention will be described below by taking the maintenance platform in a narrow space on a ship as an example. The contents not mentioned in this embodiment are the same as those in Embodiment 1.

[0058] Such as figure 1 As shown, a reversible maintenance platform 1 includes a grid 2 , a first lifting structure 31 and a second lifting structure 32 . The equipment to be overhauled 9 is installed on the height of a hull wall in the narrow space, the overhaul platform is reversibly installed under the hull wall on the same side of the equipment to be overhauled 9, the hook 62, the limit guide rail 72, the first head guide pulley 51 and the second head end guide pulley 52 are also arranged on the same side hull wall.

[0059] The grid 2 is rectangular, and its size is designed according to the size of the equipment 9 to be overhauled, and manufactured according to the CB / T608-1998 standard. The side of the grid 2 that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com