Waterproof asphalt felt laying machine

A kind of asphalt linoleum and laying machine technology, which is applied to the tools, roads, and roofs used in roofing engineering. It can solve the problems of harsh working environment, unstable construction quality, and high labor intensity, so as to improve the working environment, improve construction quality and The effect of construction efficiency and labor intensity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

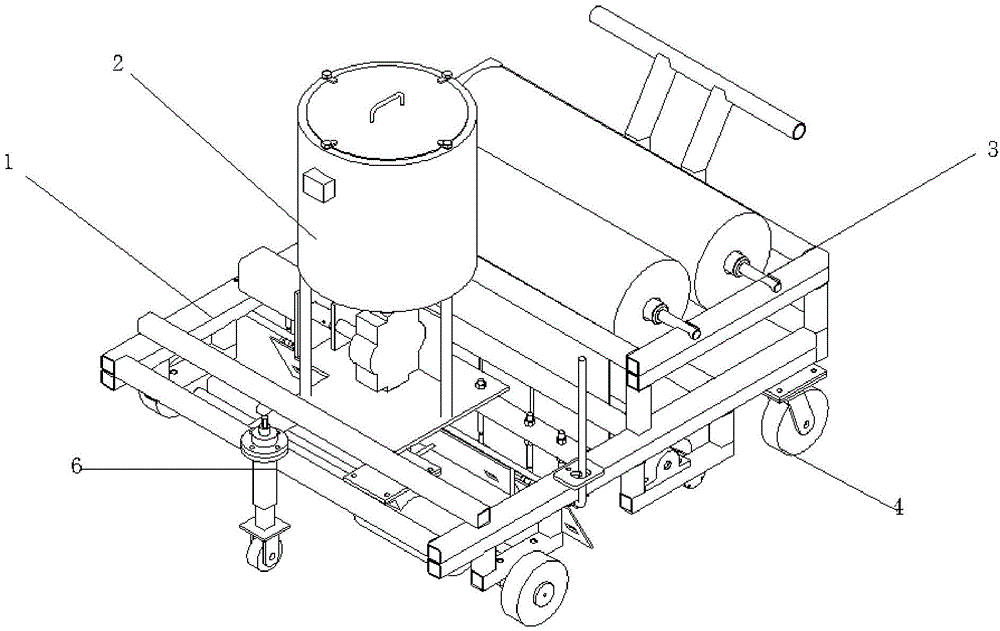

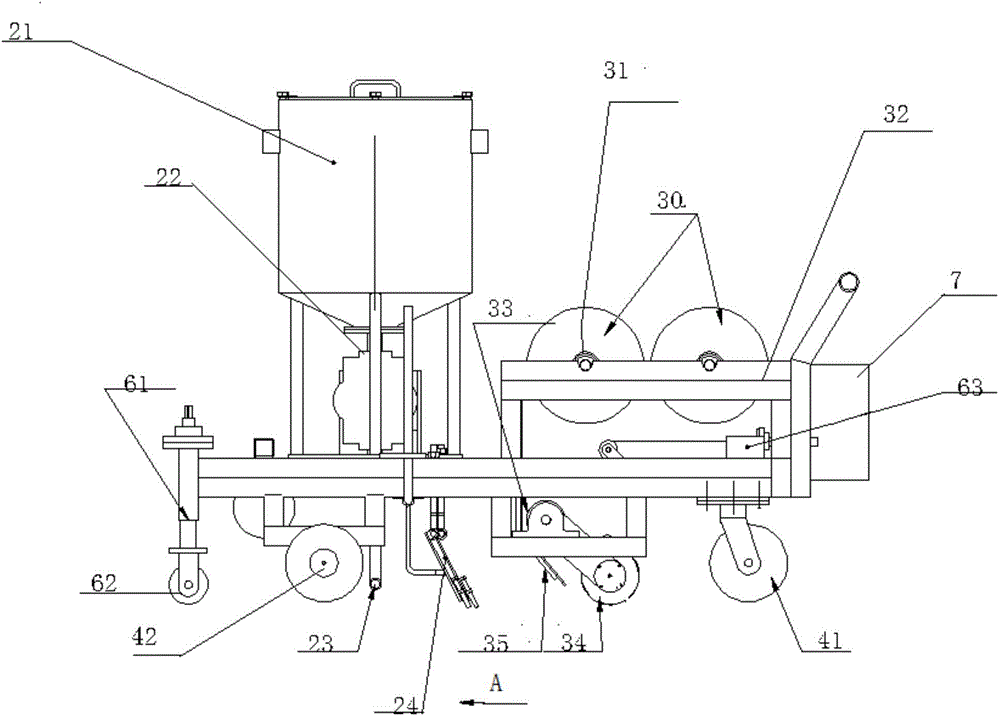

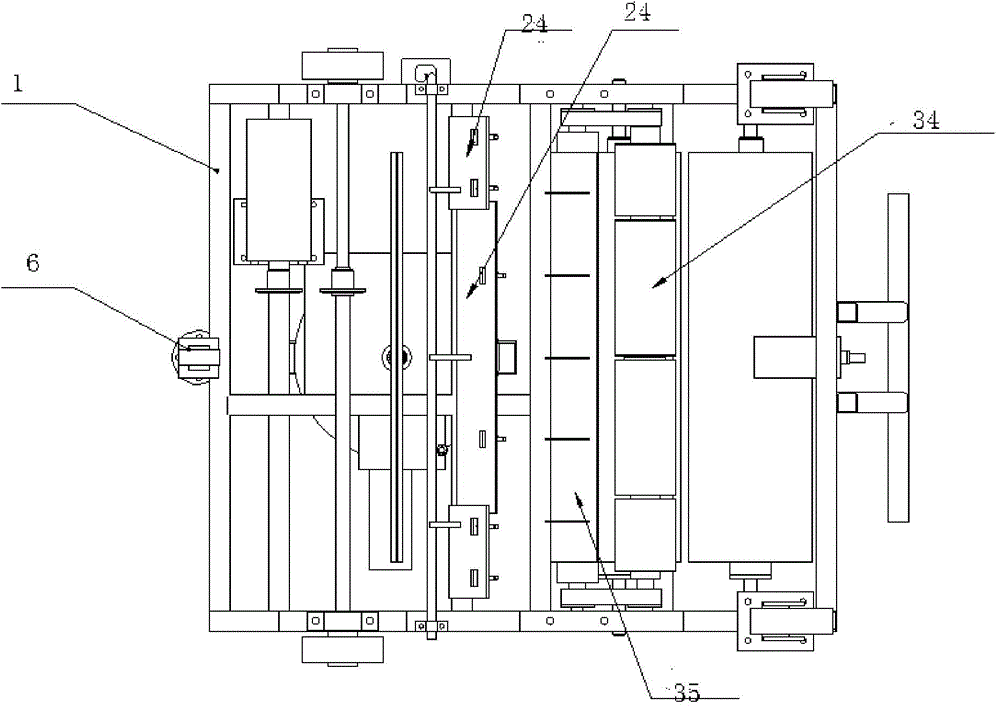

[0029] Such as figure 1 — Figure 6 As shown, the present invention includes a car body 1, an asphalt feeding and coating system 2, a felt feeding and laying system 3, a walking system 4, a feeding lifting system 5, and a traverse trolley 6;

[0030] Wherein, the vehicle body 1 is manufactured by welded section steel, and is a frame body for supporting various parts on the vehicle.

[0031] Such as figure 2 — image 3 As shown, the asphalt feed coating system 2 includes an asphalt heat preservation heating tank 21, a special asphalt valve 22, an asphalt uniform distribution pipe 23, and an asphalt scraper 24; wherein, the upper part of the asphalt heat preservation heating tank 21 for asphalt supply The heating rod, the lower part is connected with the asphal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com