Movable-arm and bucket-arm telescopic mechanical excavating mechanism controlled through crank block

A crank-slider, mechanical technology, used in mechanically driven excavators/dredgers, etc., can solve the problems of weak work, poor startability, inability to adjust the digging radius and digging depth, etc., and achieve the effect of diverse functions and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

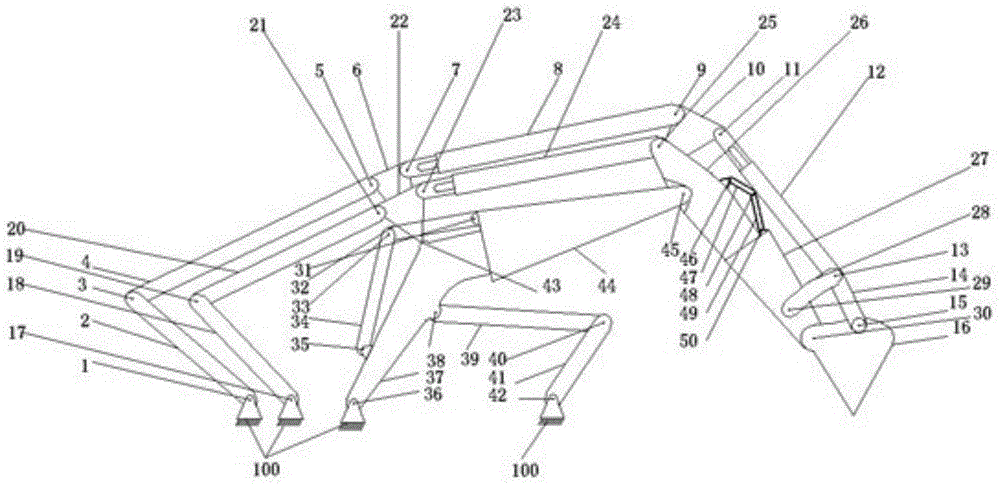

[0016] refer to figure 1 , which corresponds to a structural schematic diagram of a mechanical arm telescopic excavation mechanism that can expand the excavation depth in a preferred embodiment of the present invention. The excavation mechanism includes a plurality of motors (not shown), a frame 100, a bucket 16, a bucket Turning assembly, bucket lifting assembly, boom swing assembly, boom telescopic assembly and arm telescopic assembly, wherein, the frame 100 is used to stabilize the bucket turning assembly, bucket lifting assembly and boom swing assembly; the bucket 16 is The main working parts are used for shoveling or digging muck; the bucket turning component is mainly used to control the bucket 16 to turn inward or outward, so that the bucket 16 can take and place the muck; the bucket lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com