Wallboard interlayer connection for use at bottom enhanced part of laminated shear wall structure

A technology of interstory connection and shear wall, applied in the direction of walls, building components, building structures, etc., can solve the problem of reducing structural deformation capacity and ductility, large concrete compressive strain, and composite slab concrete shear wall structure cannot fully achieve etc. to achieve the effect of increasing ductility and deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

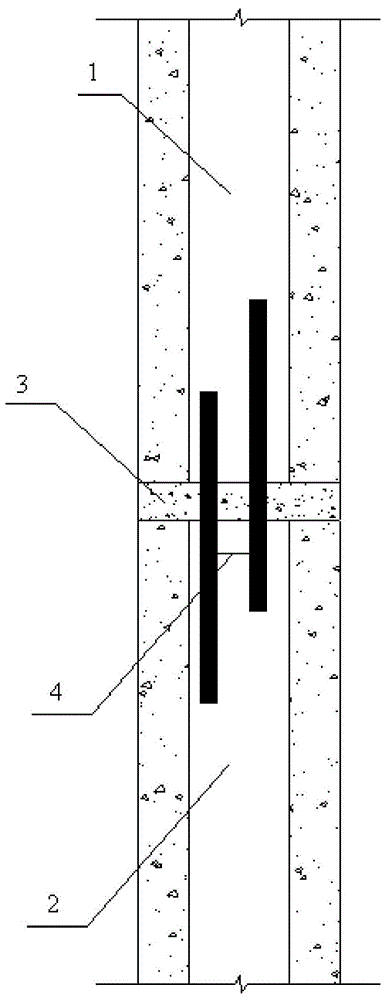

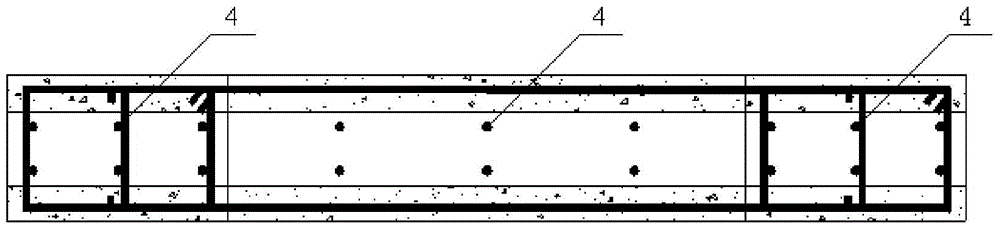

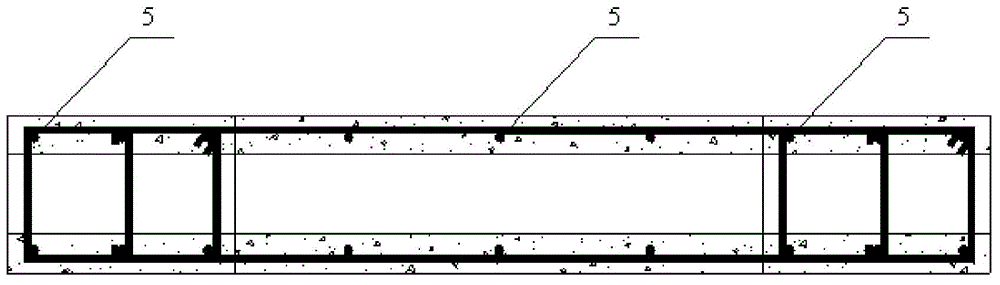

[0018] Such as Figure 1-Figure 3 As shown in the figure, the interlayer connection node of the reinforced part of a laminated slab shear wall structure includes the upper and lower laminated wallboards 1 and 2, and the upper and lower laminated wallboards 1 and 2. Concrete cushion 3, two rows of connecting steel bars 4 are reserved on the top of the cast-in-place slab in the core area of the lower laminated wall panel 2, and the connecting steel bars 4 extend into the core area of the upper laminated wall panel 1 and then connect with the upper laminated wall panel 1. The cast-in-place slab in the core area of the wallboard 1 is integrated.

[0019] Both sides of the upper and lower laminated wallboards are also provided with constraining edge members, and the diameter of the connecting steel bars in the core area of the laminated wallboard constraining edge members is not less than 12mm.

[0020] The bending moment super-strength coefficient at the horizontal seam b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com