Modular structure assembling construction method for super-high-rise building decoration tower

A technology of architectural decoration and installation method, which is applied in the direction of buildings, building types, towers, etc. It can solve the problems that large mechanical equipment cannot enter the site for construction, frequent safety accidents, and expensive shift costs, etc., to protect the lives of operators, Material saving, quality control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

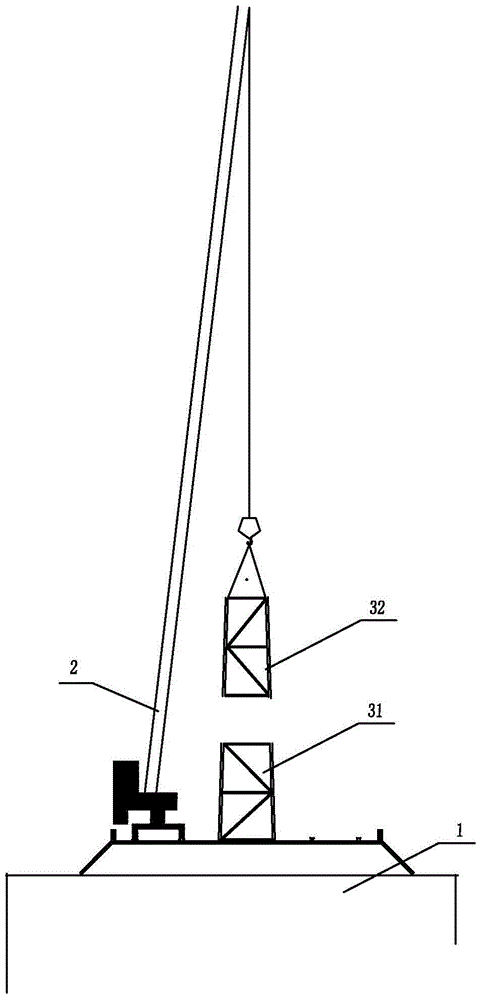

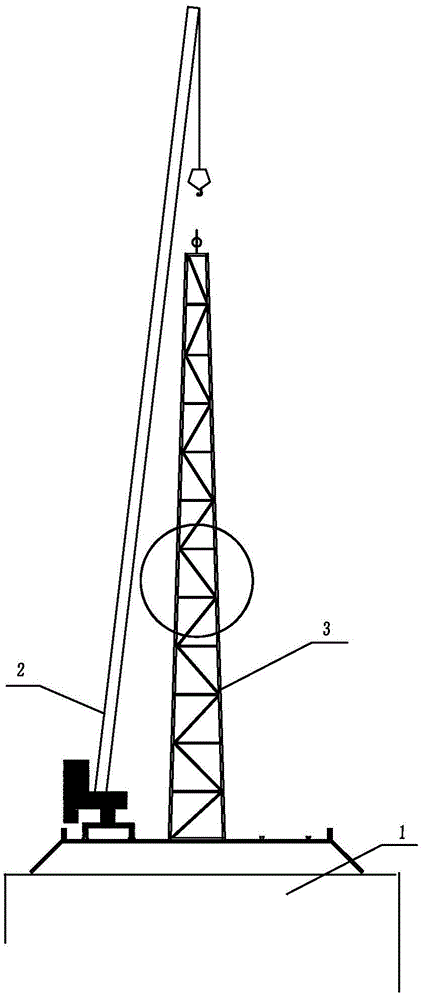

[0028] 1. A method for installing a modular structure of a decorative tower of a super high-rise building, comprising the following steps:

[0029] (1) Carry out modular decomposition design according to the shape of the decorative tower, and make the steel pipe skeleton in the factory according to the drawings;

[0030] (2) Measure the steel pipe skeleton data, build a model on the computer according to the data, and simulate the assembly of the decorative tower in advance;

[0031] (3) Check the assembly interference and analyze the assembly accuracy. According to the site temperature, humidity and wind speed at the installation height, calculate the influence of unfavorable factors on thermal expansion and contraction of components, hoisting deformation, welding stress and installation process, and determine through accurate calculation by computer The influence of various unfavorable factors on the installation, discover problems in advance, take corrective measures, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com