Automatic control device for realizing multi-stage utilization of motor vehicle exhaust

A self-control device and tail gas technology, applied in the direction of power devices, exhaust devices, components of pumping devices for elastic fluids, etc., can solve the problems of resource shortage, environmental pollution, and single use, etc., and achieve Obvious energy-saving and environmental protection effects, convenient installation and use, and wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

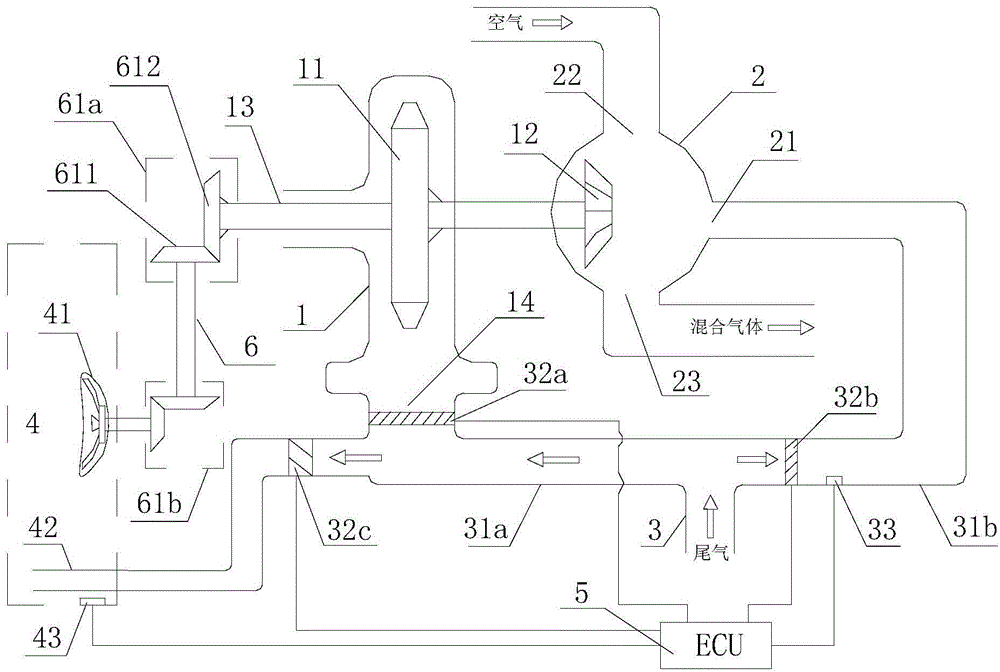

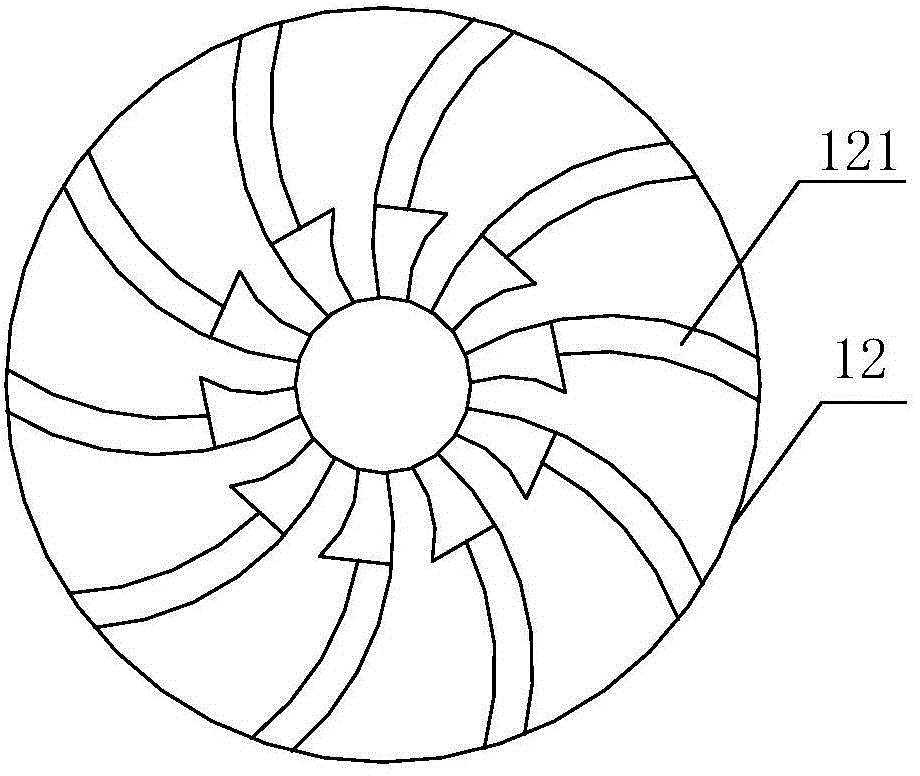

[0032] Such as figure 1 Shown: a self-control device for multi-stage utilization of motor vehicle exhaust gas provided by this embodiment, including a turbocharger 1, a gas mixing pump 2 and an exhaust pipe 3, and the turbocharger 1 includes a coaxially arranged turbine 11 and impeller 12, a transmission mechanism 6 linked with the turbine shaft 13 is provided on one side of the turbocharger 1, and the output shaft of the transmission mechanism 6 is connected with a fan 41; the gas mixing pump 2 is arranged on the The other side of the turbocharger 1, the impeller 12 is arranged inside the gas mixing pump 2; the turbocharger 1 is provided with an exhaust gas inlet 14 communicated with the exhaust pipe 3; the gas mixing The pump 2 is provided with an exhaust gas inlet 21 communicated with the exhaust pipe 3; the gas mixing pump 2 is also provided with an air inlet 22 communicated with the atmosphere and a mixed gas outlet 23 communicated with the air inlet of the internal combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com