Welding method and device for motor vehicle body components by means of lifting and lowering round table for quick tool change

A tool and body technology, applied in the field of assembly, can solve problems such as impact and achieve the effect of reducing moving loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

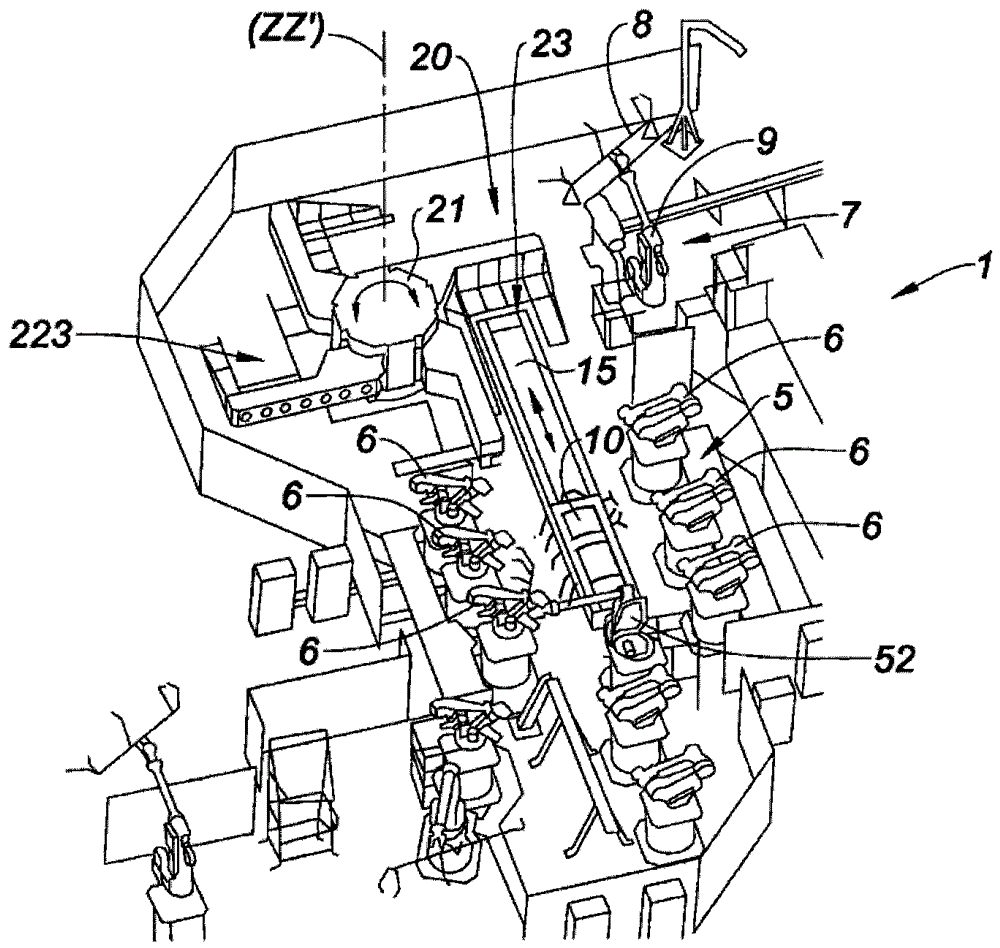

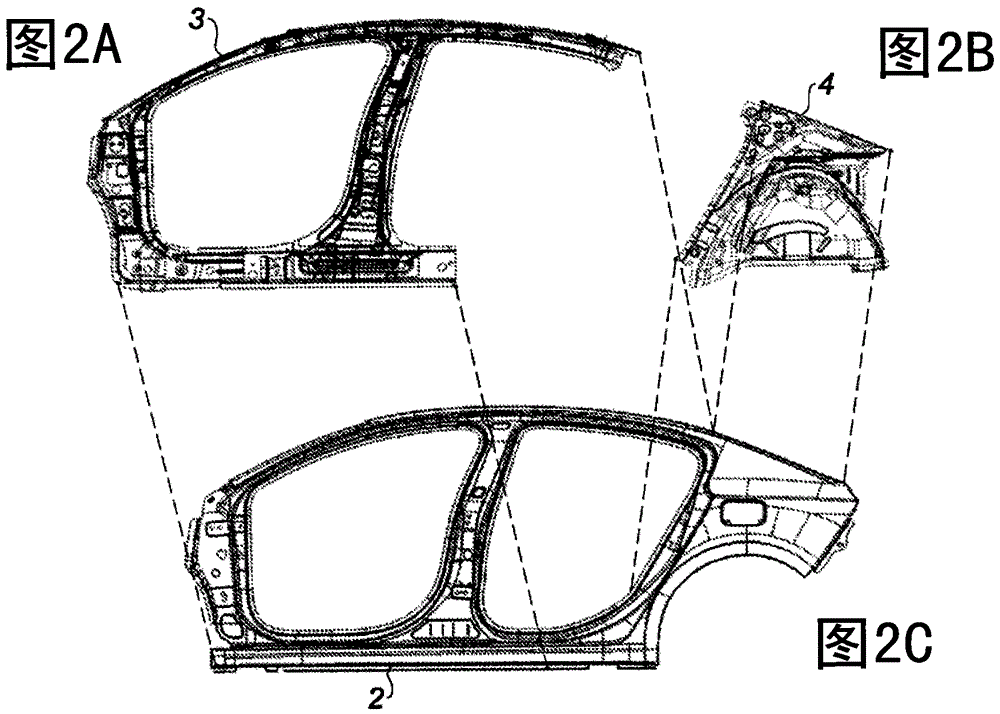

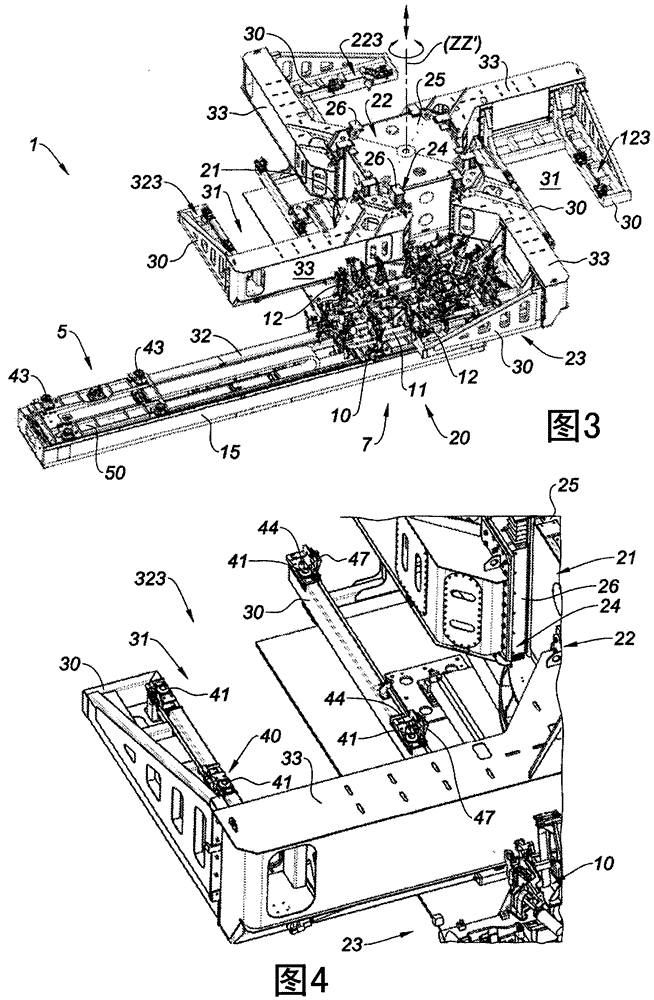

[0035] The invention relates to a device 1 for assembling body parts 2 , 3 , 4 .

[0036] Preferably, said body parts 2, 3, 4 are made of metal, especially weldable metal, but it is not excluded that said body parts can be made of glass, especially laminated glass, polycarbonate or polypropylene polymers, or even composite materials such as epoxy resin matrices reinforced with glass fibres, carbon fibres, or aramid fibres.

[0037] In particular these body parts can be preformed by molding or stamping.

[0038] The body parts 2 , 3 , 4 are preferably used to implement a body or skin surface of a vehicle, preferably a motor vehicle, in particular a land vehicle.

[0039] The device may form an assembly device for a motor vehicle, without excluding the formation of a device implementing other structures according to the principles of the invention, in particular metal structures, optionally used in other industrial fields, such as the aeronautical field.

[0040] More specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com