heat exchanger

A heat exchanger and heat medium technology, applied in the direction of heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve the problems of heat exchange volume reduction, heat exchanger performance degradation, etc., to suppress the increase of pressure loss, Effects of suppressing performance degradation and suppressing refrigerant drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

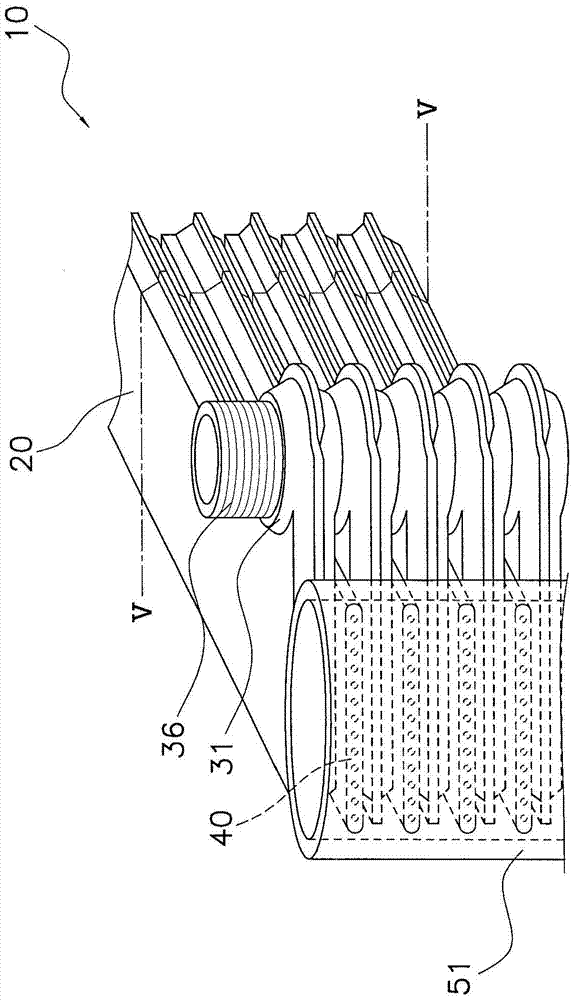

[0055] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, embodiment of the heat exchanger of this invention is not limited to embodiment demonstrated below, It can change in the range which does not deviate from the summary of invention.

[0056] The heat exchanger 10 of the present invention is used for heat exchange between HFC refrigerants including R407C, R410A, R134a and R32, HFO refrigerants including 2,3,3,3-tetrafluoro-1-propane (HFO-1234yf), etc. A heat exchanger that performs heat exchange between a refrigerant that undergoes a phase change and other heat media. As the refrigerant used, carbon dioxide (CO2) is not included 2 )Refrigerant. In addition, in the following, the case where water is used as another heat medium that exchanges heat with the refrigerant is described as an example, but the other heat medium is not limited to water.

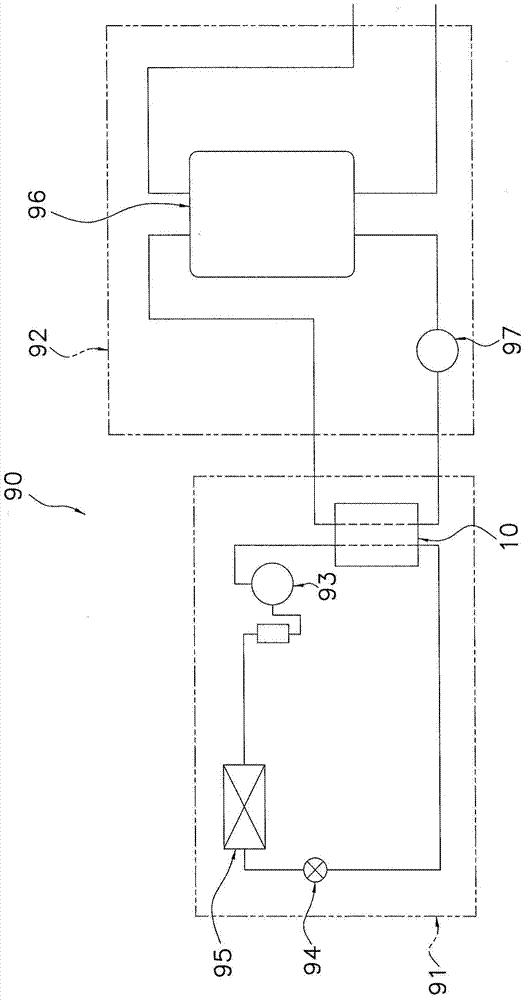

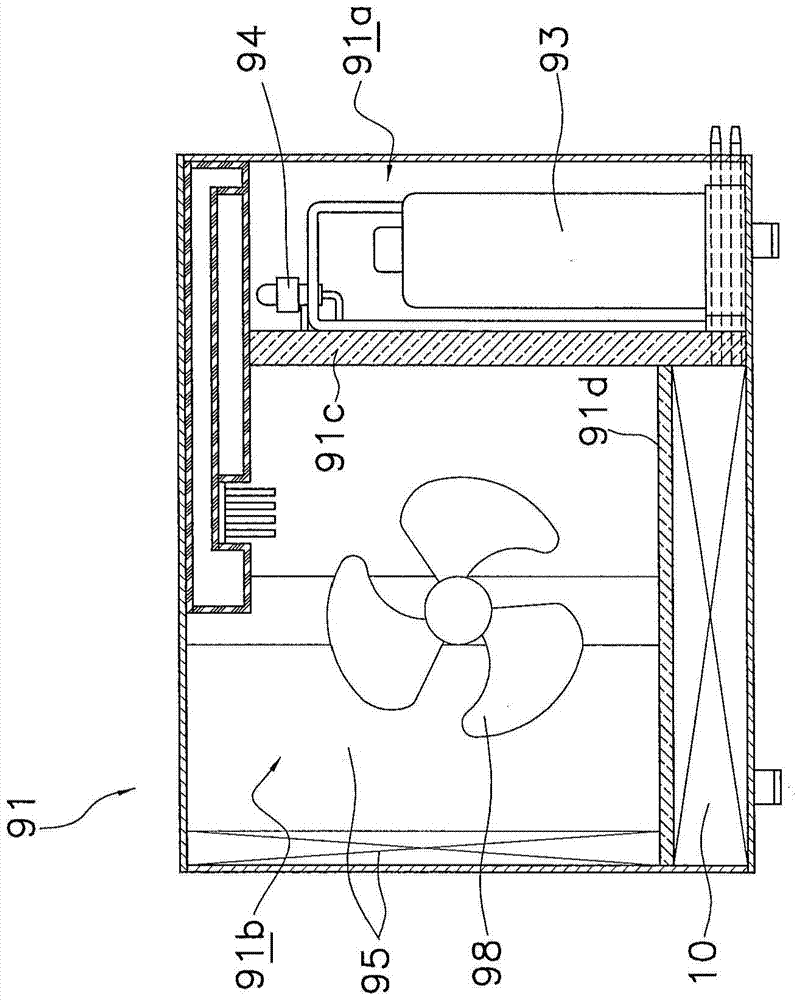

[0057] (1) Structure of heat pump hot water supply device

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com