Process for steaming fresh living fish

A fresh and crafty technology, applied in food preparation, application, food science, etc., can solve problems such as difficulty in controlling steaming time, difficulty in satisfying consumers, lack of craftsmanship standards, etc., to achieve simple production process, attractive color, good texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Pre-treatment of sea bass: first cut off the hard thorns on the back and abdomen of sea bass with scissors, then scrape off the scales, clean the gills and internal organs, clean and drain the water, break open along the belly to the tail, remove The tailbone is half cut so that the fish can lie flat on the plate.

[0029] (2) Pickling: Take the weight of sea bass as a reference to set the percentage, weigh 0.6-0.8% of salt, 0.1-0.3% of sugar, 0.1-0.2% of monosodium glutamate, 4.0-5.0% of cooking wine, and spread it evenly on the fish. Pickle at 4-8°C for 8-10 minutes.

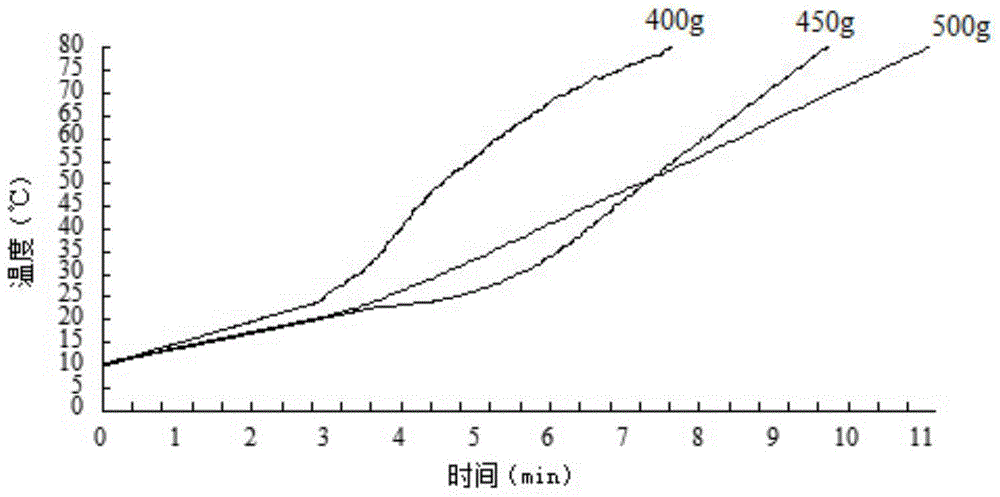

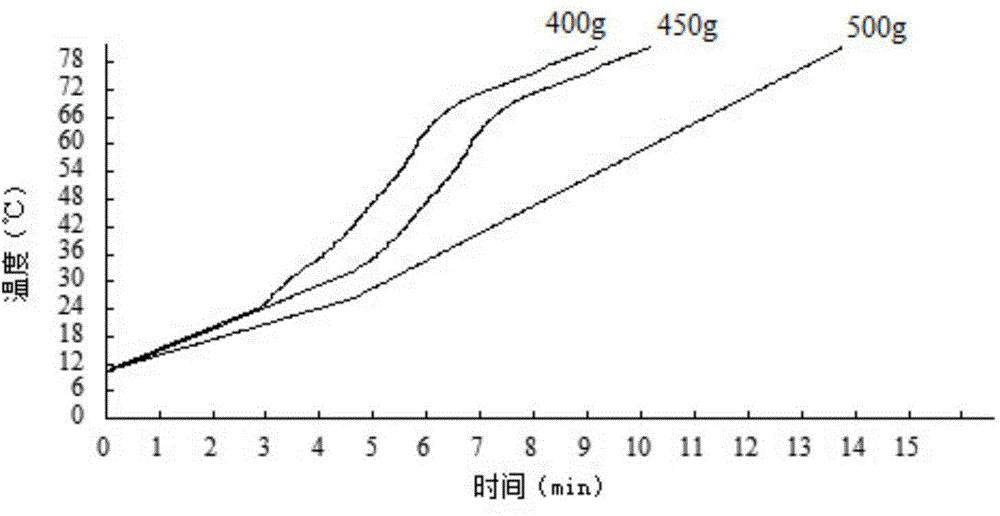

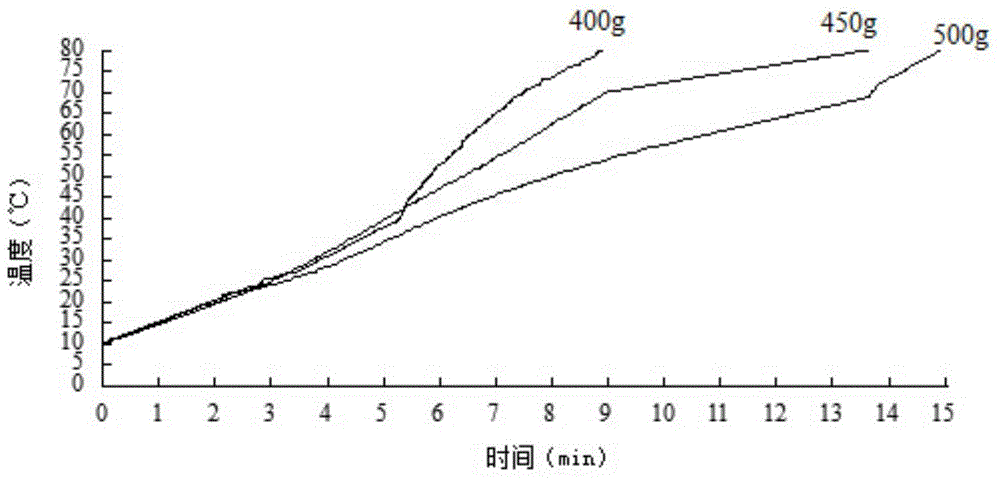

[0030] (3) Measurement of the central temperature of the fish body: insert a thermocouple into the thick central part of the back of the fish (insert 2 wires at the upper and lower ends at a certain interval), and point the thermometer to read.

[0031] (4) Cutting and matching: Cut ginger, scallion, red pepper, and yellow pepper into filaments about 5cm long. Taking the weight of the perch as a r...

Embodiment 2

[0036] (1) Pre-treatment of mandarin fish: remove the scales, gills and viscera of mandarin fish, clean and drain the water. Finally, cut three knives on the back of the fish with a depth of 2cm.

[0037] (2) Pickling: take the weight of mandarin fish as a reference to set the percentage, weigh 0.6-0.8% of salt, 0.1-0.2% of monosodium glutamate, 4.0-5.0% of cooking wine, spread it evenly on the fish, and put it in the environment of 4-8℃ Pickle for 8-10min.

[0038] (3) Measurement of the central temperature of the fish body: insert a thermocouple into the thick central part of the back of the fish (insert 2 wires at the upper and lower ends at a certain interval), and point the thermometer to read.

[0039] (4) Cutting and matching: Cut ginger, scallion, red pepper, and yellow pepper into filaments about 5cm long. Taking the weight of mandarin fish as a reference to set the percentage, weigh 0.4-0.6% of shredded ginger, 0.4-0.6% of shredded green onion, 0.6-0.8% of red pepp...

Embodiment 3

[0044](1) Pre-treatment of bream: After removing the scales, gills and viscera of the bream, wash and drain the water, and then slice the bream twice obliquely at the thicker parts of the back of the fish, with a thickness of 1cm.

[0045] (2) Pickling: Take the weight of bream as a reference to set the percentage, weigh 0.6-0.8% of salt, 0.1-0.2% of monosodium glutamate, and 4.0-5.0% of cooking wine, spread them evenly on the fish, and put them at 4-8℃ Soak for 10 minutes.

[0046] (3) Measurement of the central temperature of the fish body: insert a thermocouple into the thick central part of the back of the fish (insert 2 wires at the upper and lower ends at a certain interval), and point the thermometer to read.

[0047] (4) Cutting and matching: Cut ginger, scallion, red pepper, and yellow pepper into filaments about 5cm long. Taking the weight of the bream as a reference to set the percentage, weigh 0.4-0.6% of shredded ginger, 0.4-0.6% of shredded green onion, 0.6-0.8%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com