Application of amylase in cigar fermentation and quality improvement

A cigar and amylase technology, applied in the field of tobacco processing, can solve the problems that flue-cured tobacco enzymatic preparations cannot be applied to cigars, low sugar-to-nitrogen ratio, etc., and achieve the effects of improving use value, increasing sugar/nitrogen ratio, and balancing pH.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

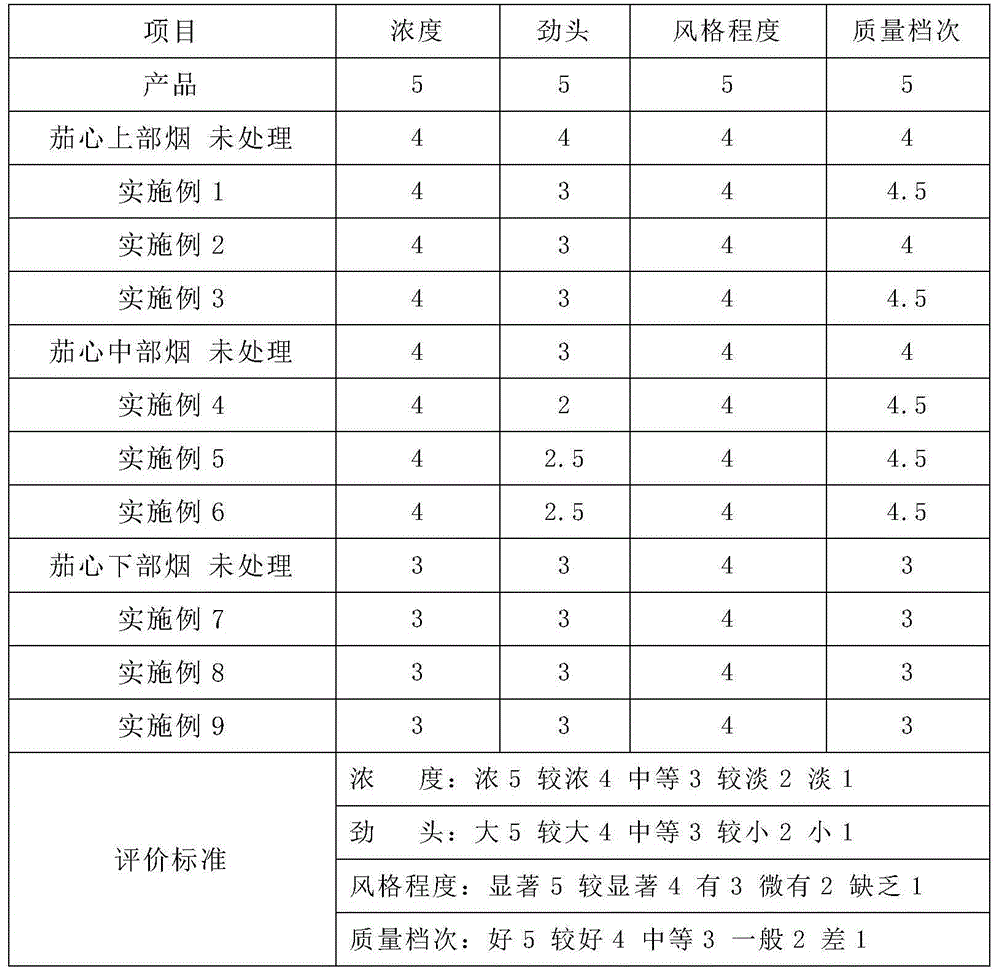

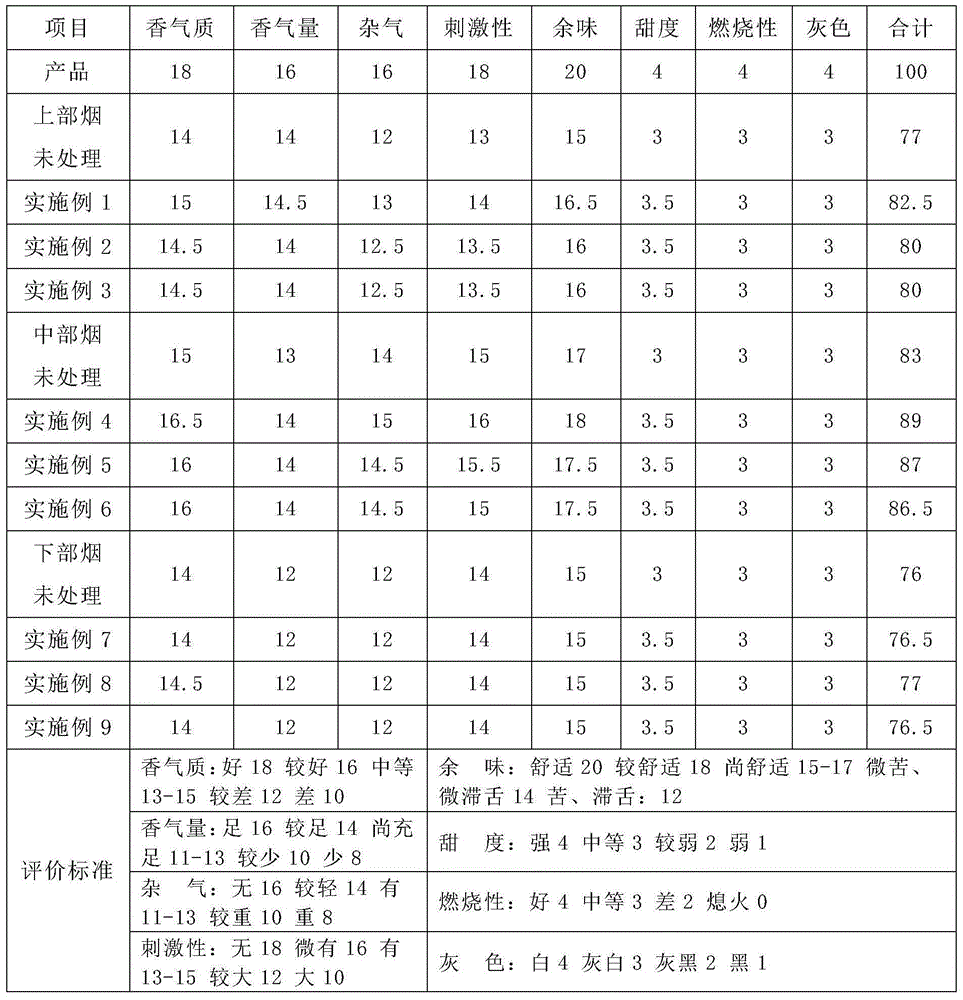

Examples

Embodiment 1

[0027] The application of amylase in cigar tobacco fermentation and quality improvement, the steps are as follows:

[0028] Dissolve the raw materials of α-amylase and glucoamylase in purified water to prepare 10kg of enzyme solution. The enzyme activity in the enzyme solution is: 80U / ml for α-amylase and 800U / ml for glucoamylase.

[0029] Vacuum the upper part of the above-mentioned cigar filler, humidify the tobacco leaves until the moisture content is 15%, soak the handle in 7kg of enzyme solution for 30 minutes, and then add 3kg of enzyme solution (the density of the obtained enzyme solution is 10% of the density of pure water) 3 kg / m 3 Calculated, the volume of 3kg enzyme solution is 3000ml) and the spray is evenly applied to 30kg tobacco leaves, that is, the mass ratio of enzyme solution spray to tobacco leaves is 1:10, and the corresponding α- Amylase is 8U and glucoamylase is 80U. After standing still for 24 hours, after the moisture is balanced, the moisture content...

Embodiment 2

[0032] Dissolve the raw materials of α-amylase and glucoamylase in purified water to prepare 10kg of enzyme solution. The enzyme activity in the enzyme solution is: 40U / ml for α-amylase and 560U / ml for glucoamylase.

[0033] Vacuum remoisturize the tobacco on the upper part of the above-mentioned cigar filler, humidify until the moisture content of the tobacco leaves is 16%, first soak the stem in 6.25kg of enzyme solution for 30min; 3 kg / m 3 Calculation) spray is evenly applied on the 30kg tobacco leaves, that is, the mass ratio of the enzyme solution spray to the tobacco leaves is 1:8, and the α-amylase corresponding to the enzyme solution spray in each gram of tobacco leaves (original tobacco) is 5U, and the glucoamylase is 5U. 70U; stand still for 12 hours, after the water balance, adjust the moisture content of the tobacco leaves to 24%, put them into the fermentation room for artificial fermentation, the environment of the fermentation room is controlled at a temperature...

Embodiment 3

[0036] Dissolve α-amylase and glucoamylase raw materials in purified water, prepare 10kg of enzyme solution, and obtain the enzyme activity in the enzyme solution: α-amylase is 60U / ml, glucoamylase is 720U / ml.

[0037] Vacuum the upper part of the above-mentioned cigar filler, humidify the tobacco leaves until the moisture content is 15%, soak the stem in 7.5kg of enzyme solution for 30 minutes, and then add 2.5kg of enzyme solution (the density of the prepared enzyme solution is 10% of the density of pure water) 3 kg / m 3 ) spray evenly applied to 30kg of tobacco leaves, that is, the mass ratio of the enzyme solution spray to the tobacco leaves is 1:12, and the α-amylase corresponding to the enzyme solution spray in each gram of tobacco leaves (original tobacco) is 5U, and the glucoamylase is 5U. 60U. After standing still for 18 hours, after the water balance, adjust the moisture content of the tobacco leaves to 26%, and put them into the fermentation room for artificial ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com