An m-shaped electric brush for cleaning culture tanks

A culture tank and electric technology, applied in the field of cleaning, can solve the problems of affecting the normal growth and development of plants, the odor of moss and scale, and the large amount of cleaning, and achieve the effect of outstanding fatigue resistance, superior impact strength, and improved cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

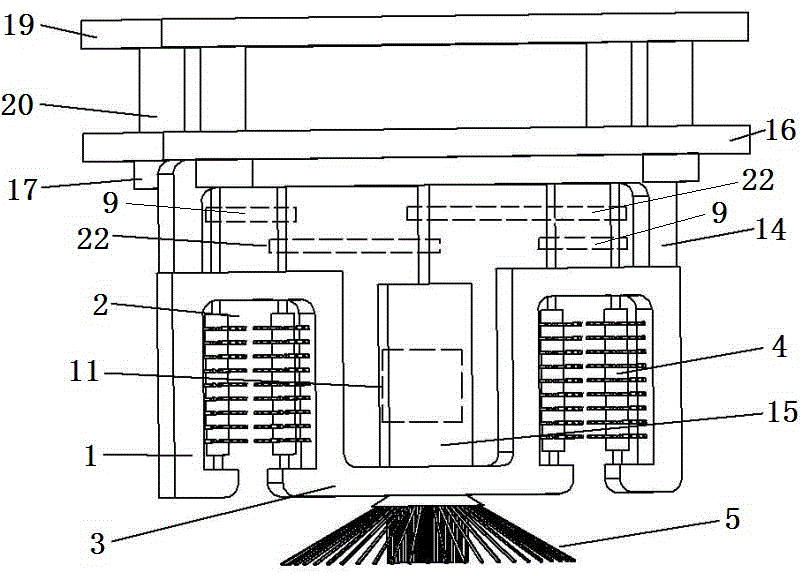

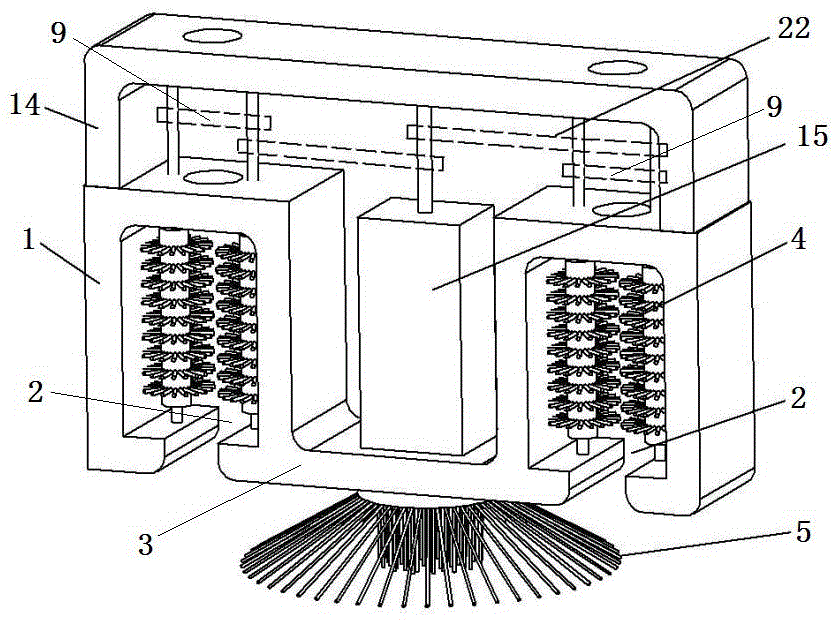

[0028] Such as Figure 1-9 As shown, an M-shaped electric brush for cleaning a culture tank includes an M-shaped brush body 1, and concave cavities 2 are provided at both ends of the brush body 1, and a convex cavity 2 is passed between two adjacent concave cavities 2. The concave cavity 2 is connected vertically with a number of rotatable roller brushes 4 driven by an electric mechanism, and the bottom of the convex part 3 is also fixed with a number of rotatable roller brushes driven by an electric mechanism. Brush 5.

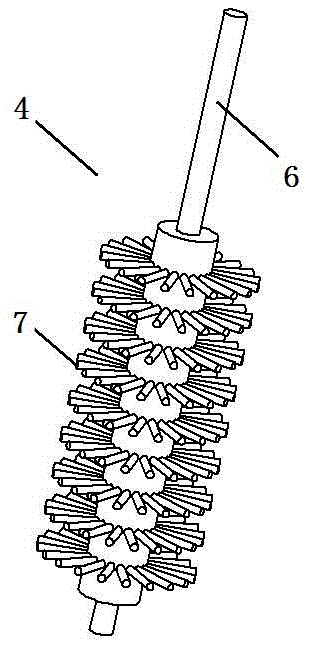

[0029] In this embodiment, at least two mutually symmetrical roller brushes 4 are respectively arranged inside the concave cavity 2, which are respectively used for cleaning both sides of the inner tank of the culture tank 10 and the two outer surfaces of the tank. The brush 4 includes a rotating shaft 6, and a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com