Water-saving textile dyeing system

A technology for water-saving systems and textiles, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of insufficient treatment of printing and dyeing wastewater, waste of energy, etc., and achieve low power consumption, cost reduction, and strong scalability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

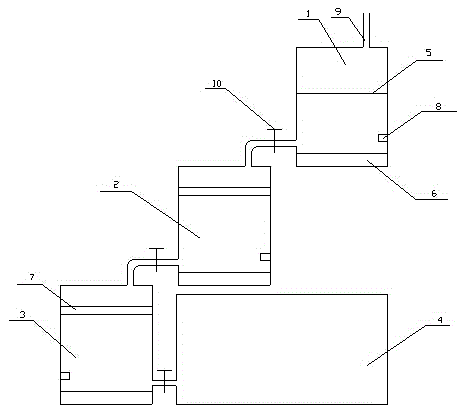

[0026] Below in conjunction with accompanying drawing, structure and working process of the present invention will be further described.

[0027] A water-saving system for textile dyeing, including an external controller, at least two sewage treatment tanks and a clean water storage tank, the sewage treatment tanks are connected in sequence, and all the sewage treatment tanks are at different physical heights, each sewage treatment tank There are two filter screens inside, and there is a gap between the two filter screens. The concentration sensor is set on the side wall of the sewage treatment tank, the water inlet is set on the upper part of the sewage treatment tank, and the water outlet is set on the bottom of the sewage tank. Then the first-level sewage treatment tank and connected to the clean water storage tank, controllable valves are set between the sewage treatment tanks and between the sewage treatment tank and the clean water storage tank, the controllable valves ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com