Camshaft assembly tool

A technology for assembling tooling and camshafts, which is applied to cams, manufacturing tools, metal processing, etc., can solve the problems that the installation quality of camshafts cannot meet the requirements, and achieve the advantages of convenient operation, safety and reliability, assembly quality assurance, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

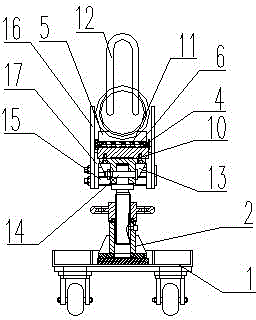

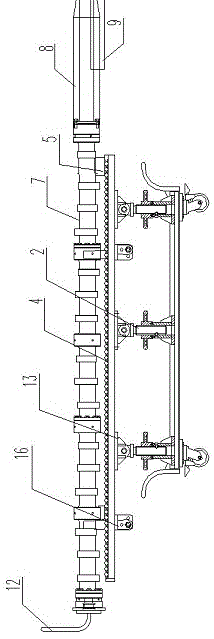

[0011] Such as figure 1 is the front view of the present invention, figure 2 It is the right side view of the present invention, and the camshaft assembly tool includes a vehicle frame 1, a lifting support seat 2, a lining plate 4, a supporting plate 5, a steel ball 6, a camshaft 7, a guide head 8, a bracket 9, a supporting frame 10, The cover plate 11 and the handle 12, the upper end of the vehicle frame 1 is provided with a lift support seat 2, the lift support seat 2 is fixedly connected with the support frame 10, the upper end of the lift support seat 2 is provided with a lining plate 4, and the upper end of the liner plate 4 is provided with a steel ball 6, The upper end cover of the steel ball 6 is provided with a cover plate 11, a supporting plate 5 is provided between the steel ball 6 and the camshaft 7, a handle 12 is provided at one end of the camshaft 7, a guide head 8 is provided at the other end, and a holder is provided at the lower end of the guide head 8 Fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com