Method for determinacy shape correction processing based on surface shape error slope

A surface shape error and processing method technology, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve problems such as increasing the uncertainty of error height, affecting processing accuracy, and affecting the effect of deterministic optical processing. To achieve the effect of avoiding conversion errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The optical part to be processed in this embodiment is a 100mm long silicon material plane mirror, and the effective length of the mirror surface is 80mm. The optical part to be processed will be taken as an example in the following, and the present invention is based on the certainty of the slope of the surface shape error The modification processing method is further explained.

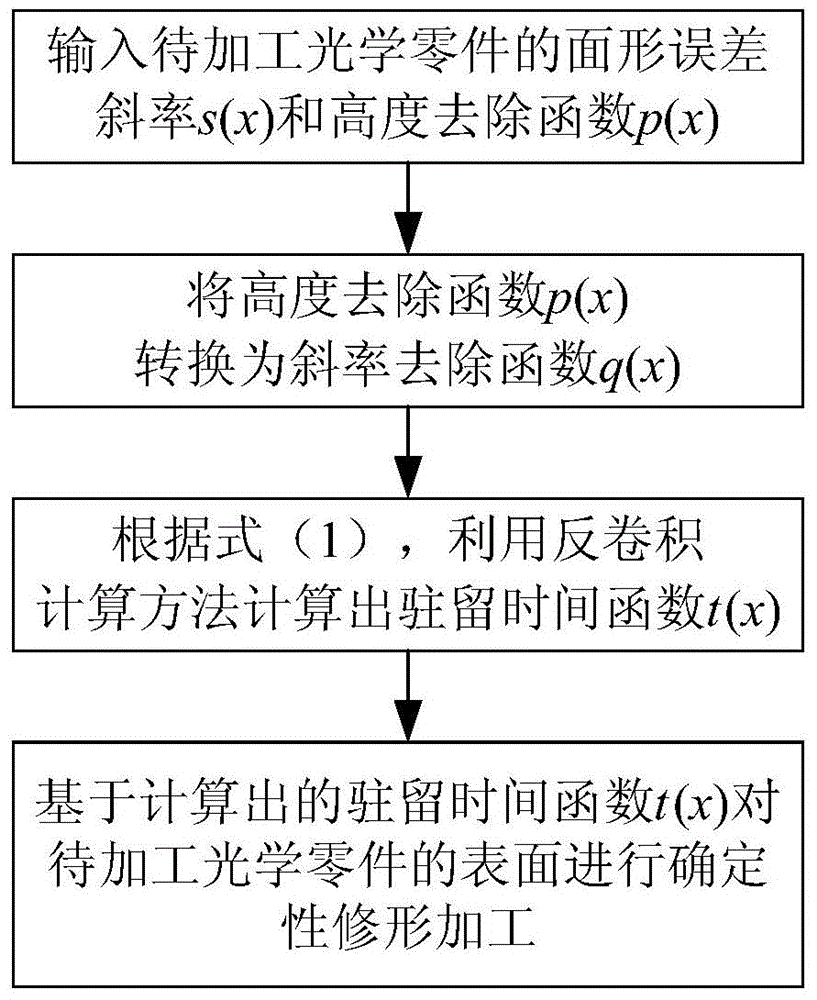

[0026] Such as figure 1 As shown, the steps of the deterministic modification processing method based on the slope of the surface error in this embodiment include:

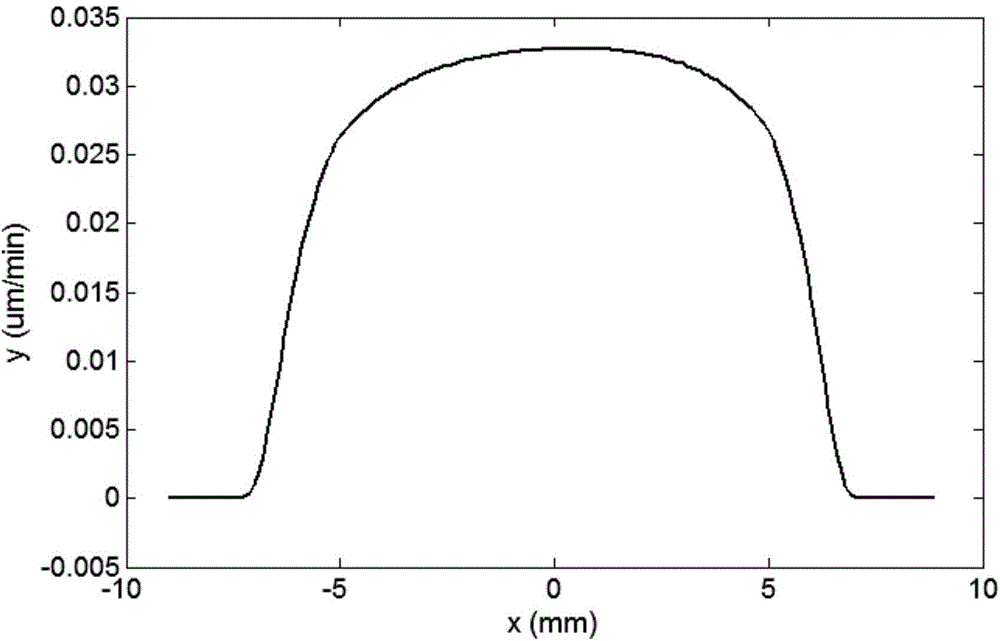

[0027] 1) Input the surface error slope s(x) and height removal function p(x) of the optical parts to be processed.

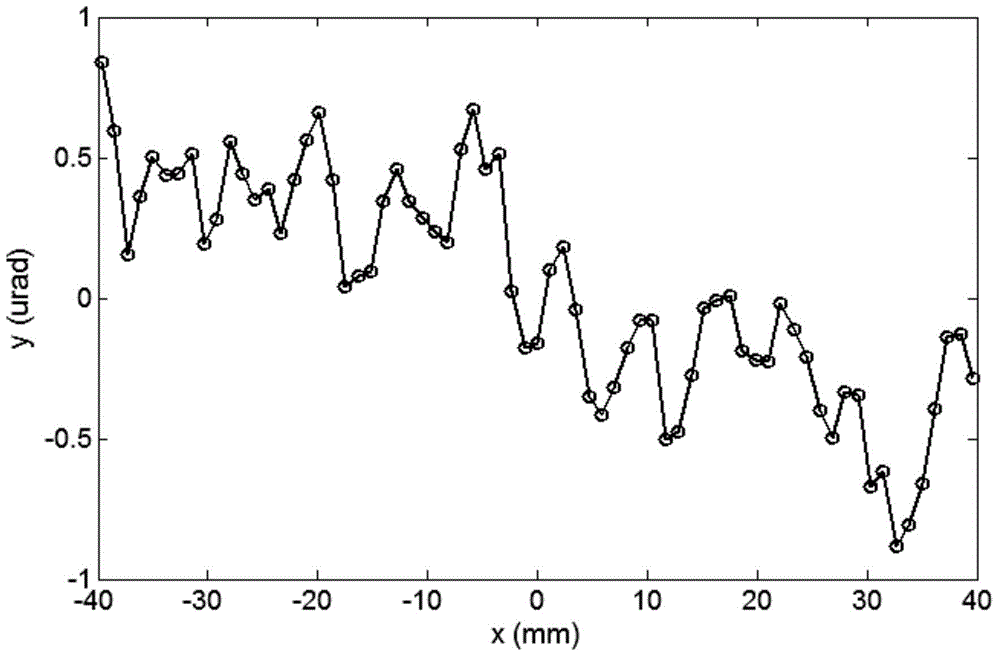

[0028] In this embodiment, the surface error slope s(x) and the height removal function p(x) are both known data, and the surface error slope s(x) is measured by a slope detector. In this embodiment, it is to be processed The slope s(x) of the surface shape error within the effective length of 80mm on the mirror surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com