Motor extrusion head for 3D printer

A technology of 3D printers and motors, applied in the direction of additive processing, etc., can solve problems such as crashing the extrusion mechanism, uneven platform, nozzles not producing filaments, etc., to reduce precision requirements, improve stability, and increase stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

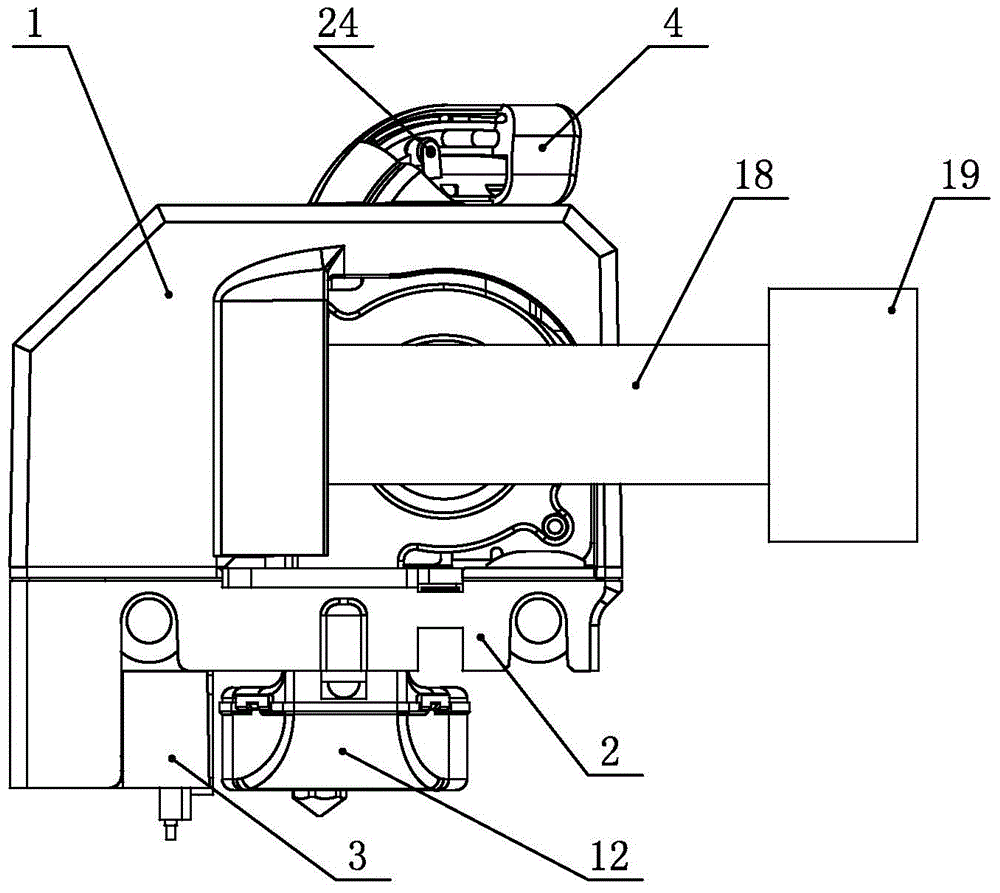

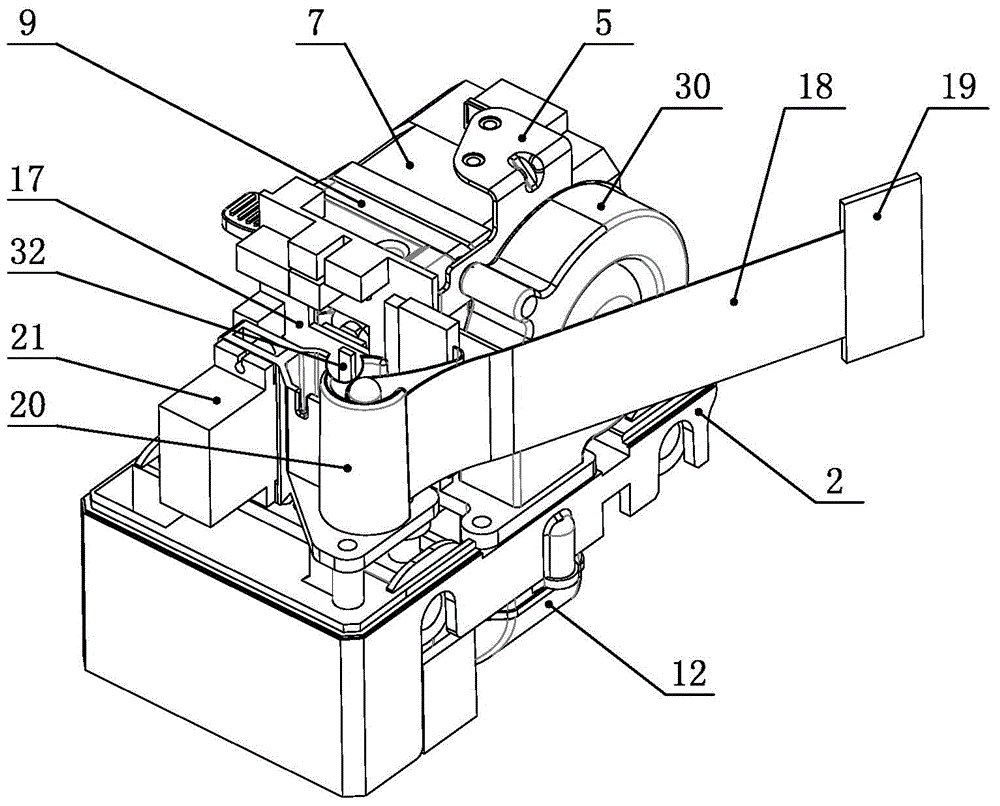

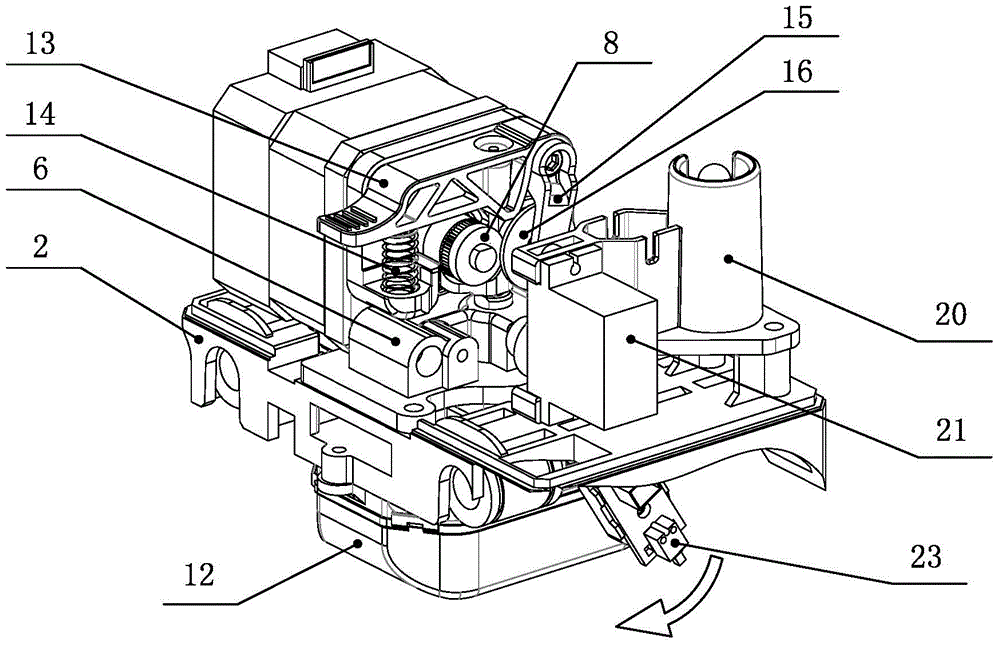

[0026] Such as Figure 1 to Figure 6Shown is a motor extrusion head for a 3D printer according to the present invention, which includes a casing 1 and a nozzle base 2. The nozzle base 2 is provided with a nozzle base cover 3, which increases the aesthetics. The casing 1 is provided with a wire inlet 4, and the wire inlet 4 conveys silk material. The casing 1 is fixedly connected with a fixed support 5, and the fixed support 5 is provided with a turbo fan 30, which mainly dissipates heat from the radiator and accelerates the cooling of the printed objects. The nozzle base 2 is provided with a motor fixing seat 6, and the motor fixing seat 6 is provided with a motor 7, and the motor 7 is rotatably connected with a wire feed wheel 8. The motor 7 is provided with a wire feeding mechanism base 9, the wire feeding mechanism base 9 is provided with a V-shaped bearing seat 13, the wire feeding mechanism base 9 is provided with a V-shaped bearing return spring 14, and the V-shaped bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com