Bag pressing location device for overhead stacker

A technology of positioning equipment and high-bit codes, which is applied to the stacking, transportation and packaging of objects, and can solve the problems of affecting the quality of the feed, the block is not easy to press the feed horizontal unit dragging, and the feed is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

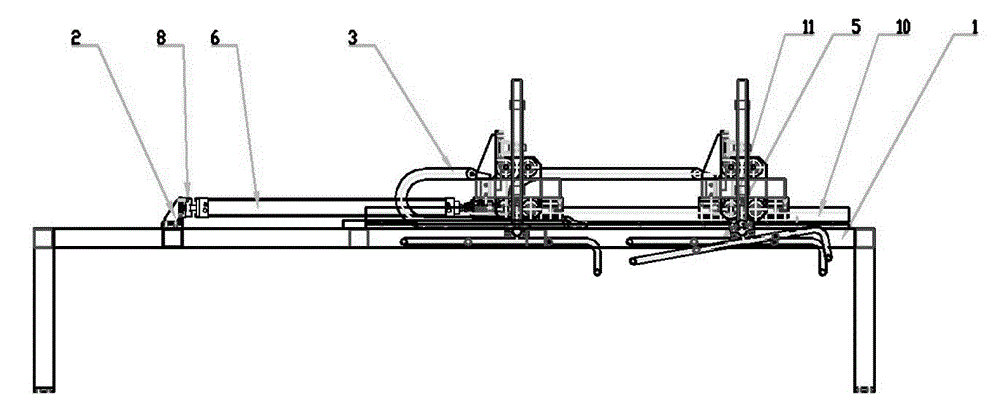

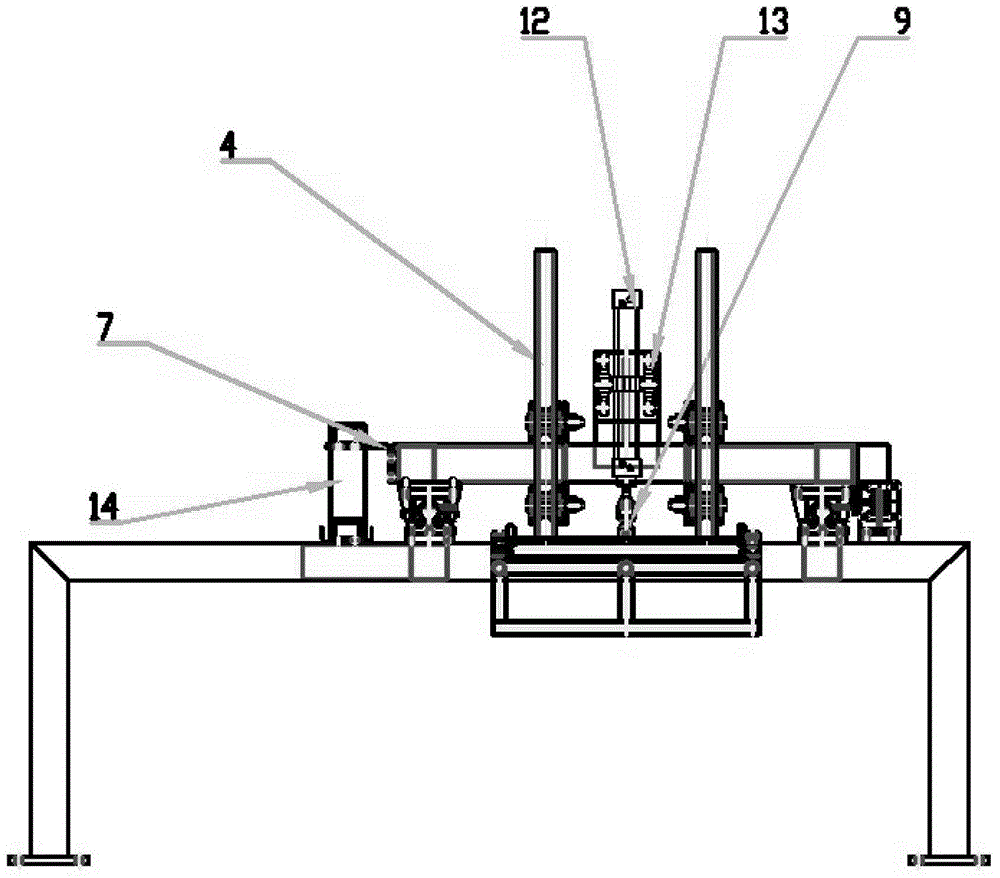

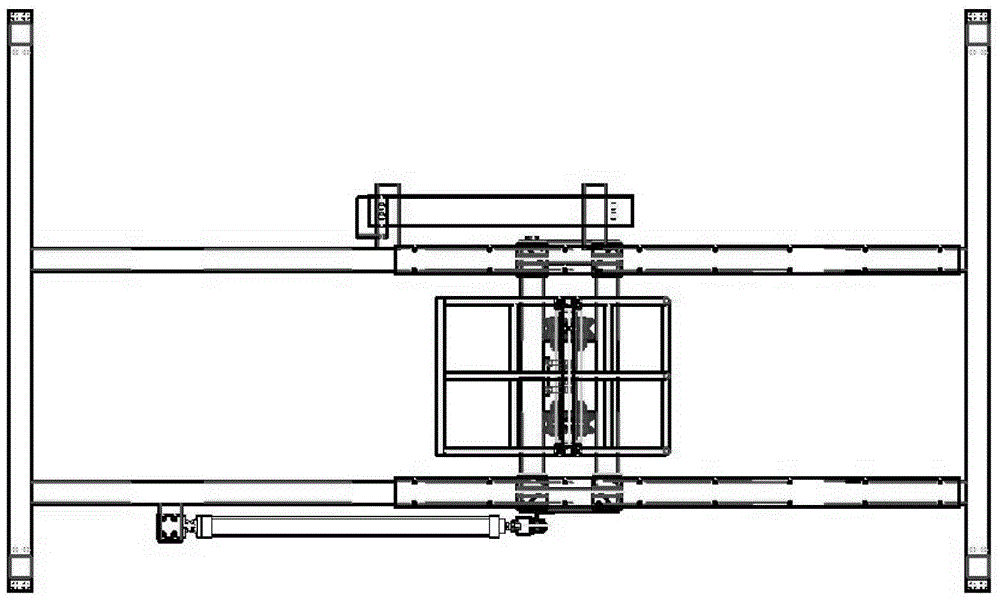

[0015] The invention provides a pressing bag positioning device of a high-position palletizer, which includes an L-shaped bag rack, a floating joint, a shift rod cylinder and an extended shift rod, and the L-shaped bag rack is connected to the shift rod cylinder through a floating joint and the L-shaped bag frame and the extended gear rod are welded together. The L-shaped bag frame moves up and down under the drive of the gear rod cylinder. Using the L-shaped bag frame will not damage the feed bag , and can overcome the troubles caused by the irregular shape of the feed bag.

[0016] Further, the press bag positioning equipment of the high-level palletizer also includes an upper frame, a cylinder seat, a telescopic cylinder, a movable frame, a drag chain bracket, a slider, a guide rail, a trunnion support, a double-ear fixing seat and a plastic drag chain.

[0017] The gear rod cylinder is fixed on the movable frame through a trunnion support.

[0018] One end of the telescop...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap