A sewage treatment process

A sewage treatment and process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of increasing sewage treatment costs, lack of carbon sources, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

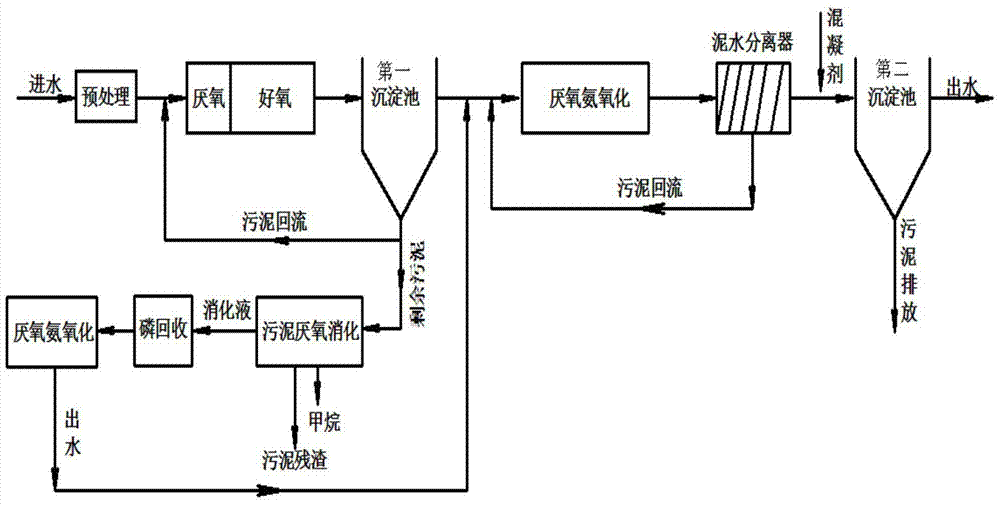

Method used

Image

Examples

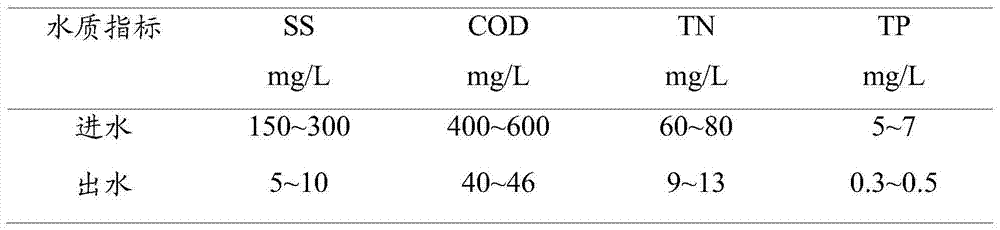

Embodiment 1

[0084] Sewage is taken to the living area of Renmin University of China, and the treatment water volume is designed to be Q=4m 3 / d, according to the following steps for sewage treatment:

[0085] Step 1: Sewage is preliminarily treated through grid grit settling to remove suspended solids with larger particle sizes, and the grid gap is 16-25mm;

[0086] Step 2: The sewage after grid grit treatment enters the anaerobic-aerobic unit, and the volume ratio of anaerobic and aerobic units in the anaerobic-aerobic unit is 1:4; the sludge age in the anaerobic-aerobic unit The water retention time is 3d, and the hydraulic retention time is 1.5h; the dissolved oxygen in the anaerobic tank is controlled below 0.2mg / L, and the dissolved oxygen in the aerobic tank is controlled at about 2mg / L;

[0087] Step 3: The mixed solution in the anaerobic-aerobic unit enters the first sedimentation tank for mud-water separation, the supernatant enters the anaerobic ammonium oxidation reactor, an...

Embodiment 2

[0101] Sewage is taken to the living area of Renmin University of China, and the treatment water volume is designed to be Q=4m 3 / d, according to the following steps for sewage treatment:

[0102] Step 1: Sewage is preliminarily treated through grid grit settling to remove suspended solids with larger particle sizes, and the grid gap is 16-25mm;

[0103] Step 2: The sewage after grid grit treatment enters the anaerobic-aerobic unit, and the volume ratio of anaerobic and aerobic units in the anaerobic-aerobic unit is 1:3; the sludge age in the anaerobic-aerobic unit is 0.5d, and the hydraulic retention time is 3h; the dissolved oxygen in the anaerobic tank is controlled below 0.2mg / L, and the dissolved oxygen in the aerobic tank is controlled at about 2mg / L;

[0104] Step 3: The mixed solution in the anaerobic-aerobic unit enters the first sedimentation tank for mud-water separation, the supernatant enters the anaerobic ammonium oxidation reactor, and part of the activated s...

Embodiment 3

[0119] Sewage is taken to the living area of Renmin University of China, and the treatment water volume is designed to be Q=4m 3 / d, according to the following steps for sewage treatment:

[0120] Step 1: Sewage is preliminarily treated through grid grit settling to remove suspended solids with larger particle sizes, and the grid gap is 16-25mm;

[0121] Step 2: The sewage after grid grit treatment enters the anaerobic-aerobic unit, and the volume ratio of anaerobic and aerobic units in the anaerobic-aerobic unit is 1:5; the sludge age in the anaerobic-aerobic unit 5d, hydraulic retention time is 0.5h; the dissolved oxygen in the anaerobic tank is controlled below 0.2mg / L, and the dissolved oxygen in the aerobic tank is controlled at about 2mg / L;

[0122] Step 3: The mixed solution in the anaerobic-aerobic unit enters the first sedimentation tank for mud-water separation, the supernatant enters the anaerobic ammonium oxidation reactor, and part of the activated sludge after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com