Enamel material and preparation method and application thereof

An enamel and glaze technology, applied in the field of enamel materials and their preparation, can solve the problems of decreasing microwave output efficiency, accelerating diffusion speed, restricting the application of enamel materials, etc., and achieving the effects of improving microwave output efficiency and low microwave absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

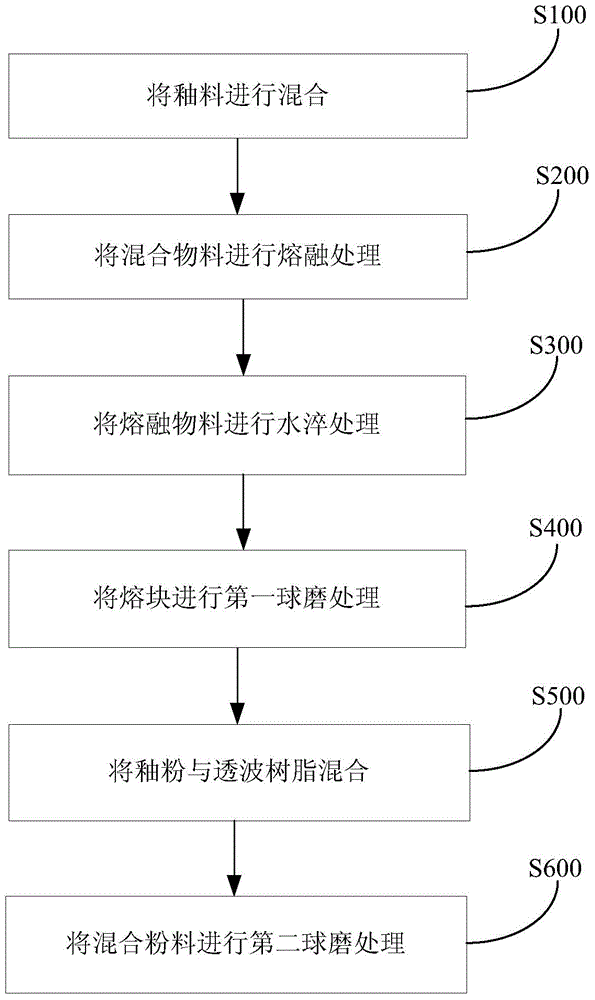

Method used

Image

Examples

Embodiment 1

[0061] The composition of the enamel material: the oxide of the first main group metal element: 18 parts by weight of Li 2 0, 6 parts by weight of Rb 2 O, 11 parts by weight of K 2 O; oxides of elements of the third main group: 2 parts by weight of B 2 o 3 , 3 parts by weight of Al 2 o 3 ; Oxides of the fourth subgroup element: 22 parts by weight of TiO 2 , 3 parts by weight of HfO 2 , 7 parts by weight of ZrO 2 ; The oxide of the fourth main group element: 17 parts by weight of SiO 2 , 4 parts by weight of SnO 2 ; Oxides of the fifth main group element: 2 parts by weight of Sb 2 o 3 , 1 part by weight of Bi 2 o3 ; The oxide of the fifth subgroup element: 1 part by weight of V 2 o 5 ; Oxides of the second subgroup element: 1 part by weight of ZnO; Oxides of lanthanide elements: 0.2 parts by weight of Ce 2 o 3 , 0.2 parts by weight of Yb 2 o 3 , 0.1 parts by weight of Pr 6 o 11 ; Wave-transparent resin: 1.5 parts by weight of polyether ether ketone.

[0062]...

Embodiment 2

[0064] The composition of the enamel material: the oxide of the first main group metal element: 10 parts by weight of Li 2 O, 15 parts by weight of Na 2 O, 15 parts by weight of K 2 O; oxides of elements of the third main group: 3 parts by weight of B 2 o 3 ; Oxides of the fourth subgroup element: 20 parts by weight of TiO 2 , 4 parts by weight of HfO 2 ; The oxide of the fourth main group element: 23 parts by weight of SiO 2 , 2 parts by weight of SnO 2 ; Oxides or / and inorganic salts of the fifth main group element: 3 parts by weight of Na 3 PO 4 , 1 part by weight of Bi 2 o 3 ; Oxides of the fifth subgroup element: 1 part by weight of Nb 2 o 5 ; Oxides of the second subgroup element: 1 part by weight of ZnO; Oxides of lanthanide elements: 0.2 parts by weight of Ce 2 o 3 , 0.2 parts by weight of Nd 2 o 3 ; Wave-transparent resin: 1.6 parts by weight of polyamide-polyimide.

[0065] Preparation method: melting treatment at 1000°C, second ball milling treatment...

Embodiment 3

[0067] The composition of the enamel material: oxides of metal elements of the first main group: 8 parts by weight of Li 2 O, 3 parts by weight of Ce 2 O, 6 parts by weight of K 2 O; oxides of elements of the third main group: 5 parts by weight of Al 2 o 3 , 1 part by weight of B 2 o 3 ; Oxides of the fourth subgroup element: 30 parts by weight of TiO 2 , 2 parts by weight of HfO 2 ; The oxide of the fourth main group element: 29 parts by weight of SiO 2 ; Oxides or / and inorganic salts of the fifth main group element: 12 parts by weight of Na 3 PO 4 ; The oxide of the fifth subgroup element: 1 part by weight of V 2 o 5 ; Oxides of the second subgroup element: 1 part by weight of ZnO; Oxides of lanthanide elements: 0.3 parts by weight of Pr 6 o 11 , 0.2 parts by weight of Nd 2 o 3 , 0.2 parts by weight of Yb 2 o 3 ; Wave-transparent resin: 1.3 parts by weight of polyimide.

[0068] Preparation method: melting treatment at 900°C, second ball milling treatment fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com