Modified raw soil material

A soil-generating technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as the lack of deformation capacity of raw-earth buildings, prolong earthquake resistance time, and realize recycling Use and improve the effect of deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

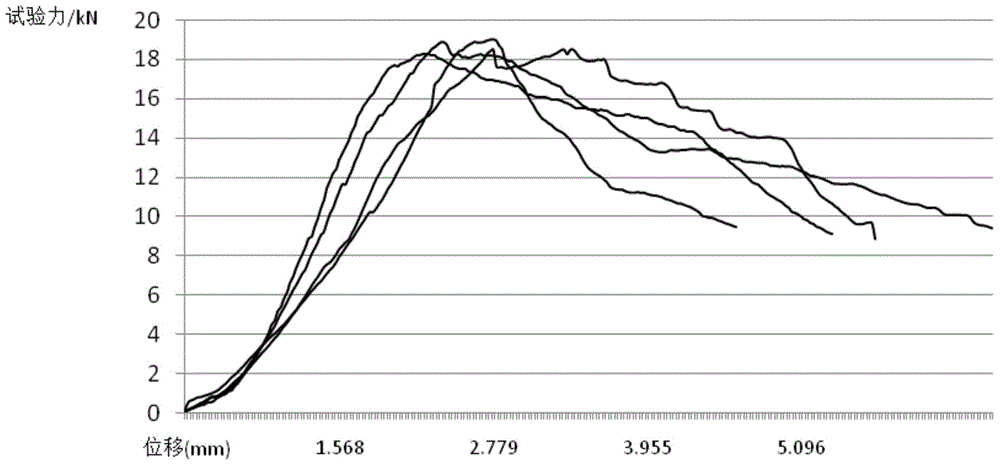

Embodiment 1

[0035] The present embodiment provides a kind of modified raw soil material, by weight unit, is made up of following raw material: 100 parts of raw soil, 5 parts of glass slag, 0.2 part of bamboo fiber, 13 parts of glutinous rice pulp, wherein water 100 parts when making glutinous rice pulp 3 servings of glutinous rice. Preparation:

[0036] Weigh 2kg of water, mix 60g of glutinous rice with water, and cook for about 25 minutes until boiled;

[0037] The glutinous rice is filtered, and the glutinous rice slurry is cooled, and the glutinous rice slurry of 13% of the raw soil quality is weighed;

[0038] The glass is pulverized, sieved with a 5mm sieve, and weighs 5% glass slag of raw soil quality;

[0039] Bamboo fiber is pulverized, chooses the bamboo fiber of 1~2cm length, takes the bamboo fiber of 0.2% of raw soil mass;

[0040] Mix raw soil, glutinous rice pulp, glass slag, and bamboo fiber to obtain the modified raw soil material of this embodiment.

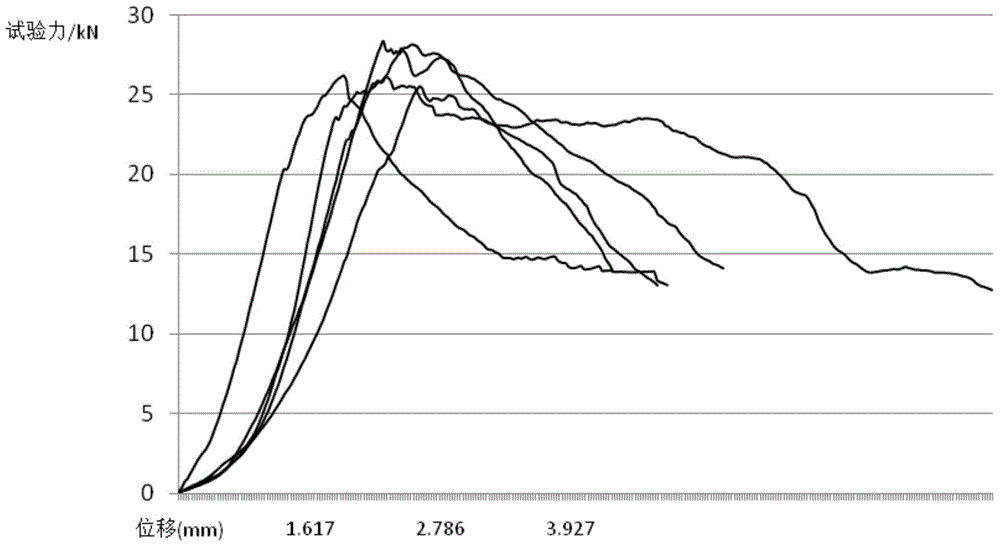

Embodiment 2

[0042] The present embodiment provides a kind of modified raw soil material, by weight unit, is made up of following raw material: 100 parts of raw soil, 10 parts of glass slag, 0.5 part of bamboo fiber, 13 parts of glutinous rice pulp, wherein water 100 parts when making glutinous rice pulp Part, 3 parts of glutinous rice, preparation method is the same as embodiment 1.

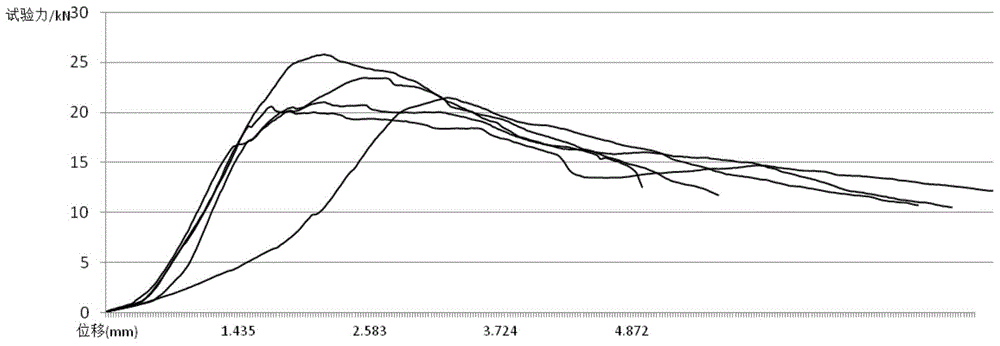

Embodiment 3

[0044] The present embodiment provides a kind of modified raw soil material, by weight unit, is made up of following raw material: 100 parts of raw soil, 15 parts of glass slag, 0.8 part of bamboo fiber, 13 parts of glutinous rice pulp, wherein water 100 parts when making glutinous rice pulp Part, 3 parts of glutinous rice, preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com