Single screw extrusion desulphurization and post-treatment system, and reclaimed rubber preparation method

A single-screw extrusion and single-screw technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes, etc., can solve the problems of difficult cooling of materials, difficult maintenance, difficult manufacturing, etc. Achieve appropriate shear strength, low operating cost, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] specific implementation plan

[0034] The preferred examples of the present invention are given below to further illustrate the present invention, but not to limit the present invention.

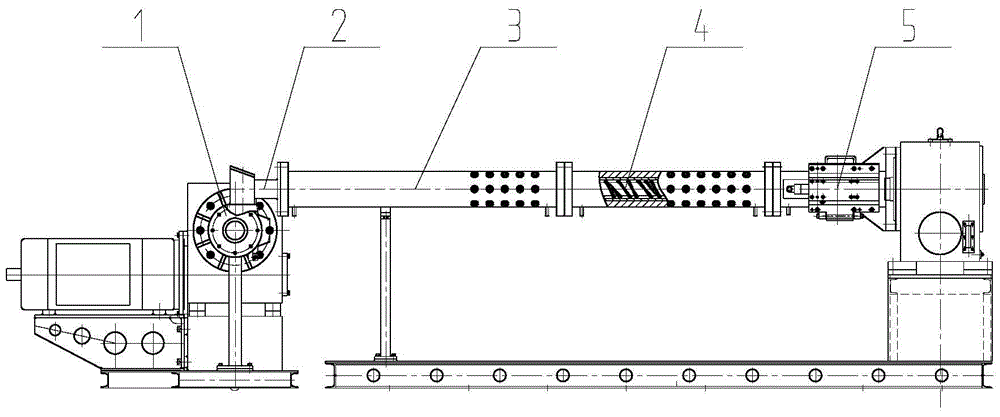

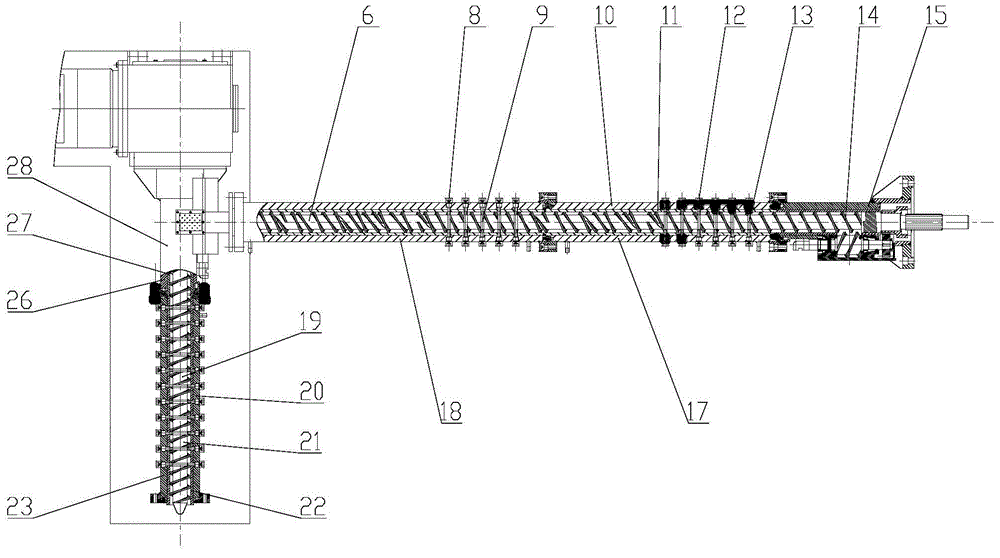

[0035] as attached figure 1 , figure 2 As shown, the single-screw extrusion desulfurization and post-processing system includes single-screw desulfurization equipment 3, single-screw post-processing equipment 1, and a closed connection device 2 connecting single-screw desulfurization equipment 3 and single-screw post-processing equipment 1.

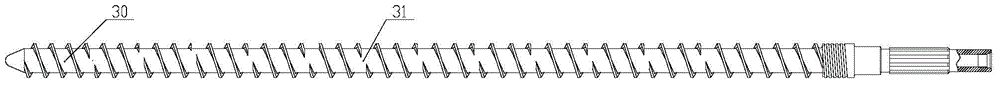

[0036] The single-screw desulfurization equipment 3 includes a desulfurization feeding device 5 and a desulfurization device 4 connected to each other, and a desulfurization screw 6 running through the desulfurization feeding device 5 and the desulfurization device 4. The desulfurization screw 6 is connected to the main shaft of the first reduction box. The feeding device 5 , the desulfurization device 4 and the desulfurization screw 6 are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com