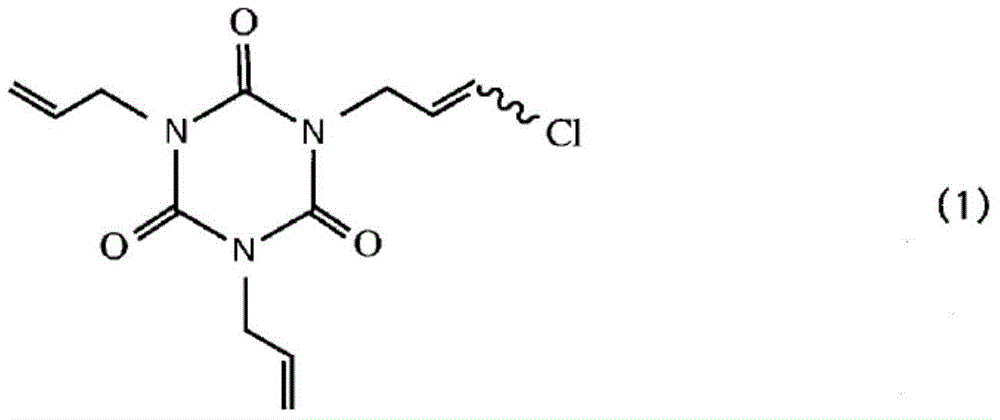

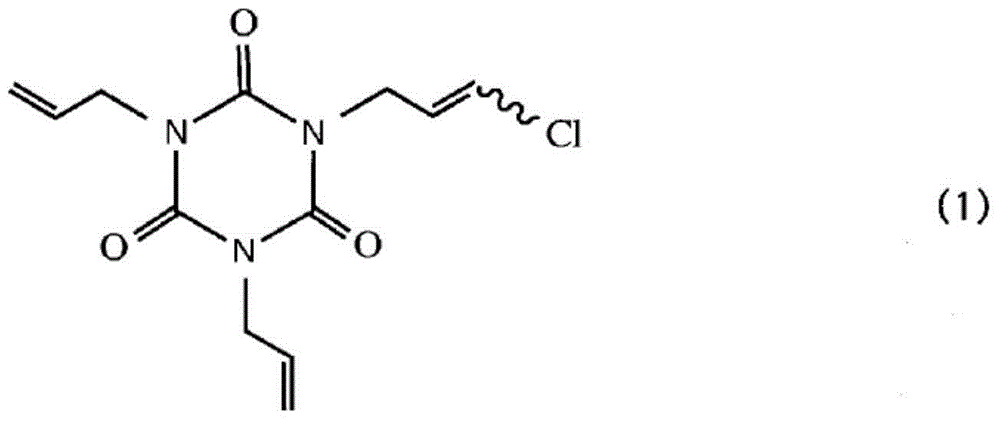

Triallylisocyanurate and process for production thereof

A technology of triallyl cyanurate and crosslinking agent, applied in the direction of organic chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Hereinafter, although an Example demonstrates this invention in more detail, this invention is not limited to the following Example unless the summary is exceeded. The analysis method in each of the following examples is as follows.

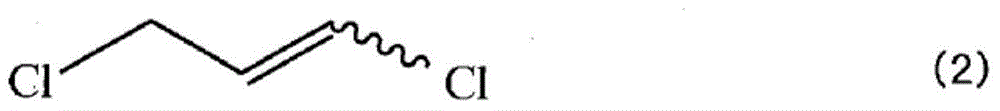

[0042] (1) Analysis of 1,3-dichloropropene:

[0043] This analysis was performed by single ion monitoring (SIM) using GC-MS (Gas Chromatograph-Mass Spectrometry). Table 1 shows the analysis conditions. Among them, the detection limit is 0.5ppm. In Comparative Example 1, the analysis sample of 1,3-dichloropropene was diluted 20 times and used.

[0044] [Table 1]

[0045]

[0046] (2) Analysis of the organochlorine compound of chemical formula (I):

[0047] The analysis was performed by gas chromatography (area percentage method). Table 2 shows the analysis conditions. Among them, the detection limit is 10 ppm.

[0048] [Table 2]

[0049]

Embodiment 1

[0053] In Comparative Example 1, 1,3-dichloropropene (containing 0.1 ppm of allyl chloride in the cis form and 0.1 ppm in the trans form) was used as the raw material allyl chloride, and the procedure was the same as in Comparative Example 1 operation to produce TAIC (yield 91%). In this TAIC, organochlorine compounds of general formula (I) were not detected (less than 10 ppm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com