High-solid low-chlorine water repellent agent and preparation method thereof

A water-resistant agent and high-solid technology, applied in the direction of adding water-repellent agents, can solve problems such as affecting purity and other quality, reducing water-resistance performance, and product loss of water-repellent agents, so as to eliminate by-products of chlorine-containing organic substances, eliminate The effect of production and reduction of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

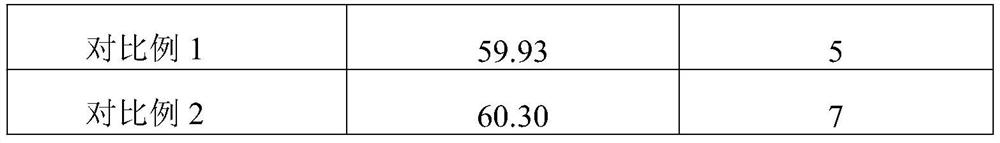

Examples

Embodiment 1

[0020] Preparation of a high-solid and low-chlorine water-resistant agent: Add 200g of adipic acid and 90g of diethylenetriamine mixture into a three-necked flask, and react at 160°C for 4 hours. During the reaction, it is continuously separated from the system Moisture; Add 50g of hot deionized water and increase the stirring speed; After cooling the system to 80°C, add 100g of urea, 12g of epichlorohydrin, 68g of water and 6g of colchicine, react at 75°C for 6h; then add 12g of dilute sulfuric acid neutralizes the pH of the system to 6-8, and cools to obtain the final anti-water agent product.

Embodiment 2

[0022] Preparation of a high-solid and low-chlorine water-resistant agent: Add 210g of adipic acid and 100g of diethylenetriamine mixture into a three-necked flask, and react at 170°C for 5 hours. During the reaction, it is continuously separated from the system Moisture; Add 50g of hot deionized water, increase the stirring speed; After cooling the system to 80°C, add 110g of urea, 10g of epichlorohydrin, 70g of water and 7g of ephedrine, react at 75°C for 6h; then add dilute 12g of hydrochloric acid neutralizes the pH of the system to 6-8, and cools to obtain the final anti-water agent product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com