Environmentally-friendly 90-DEG C polyvinyl chloride cable insulating material

A polyvinyl chloride cable and insulating material technology, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., and can solve the problems of harmful substances such as heavy metal elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

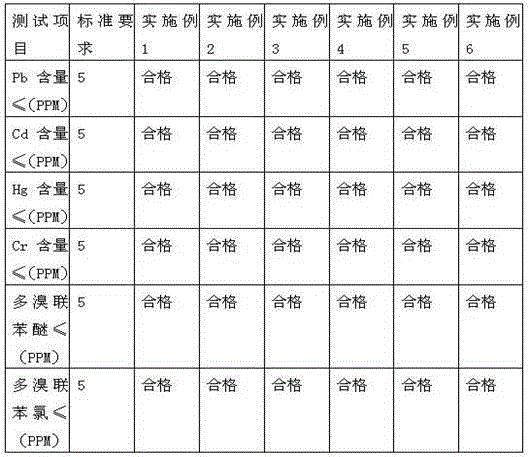

Examples

Embodiment 1

[0026] Weigh the raw materials in the following proportions by weight: 20 kg of 2-phenyl-2,3-diazaspiro[4.5]decane-1,4-dione, 2-(phosphonooxy)acrylic acid cyclohexylamine salt 38kg, 1,3-butanedioneamine 17kg, 1-acetyl-2-imidazolinone 16kg, ethyl acetylacetonate 34kg, 1,1-diphenyl-4-(1-piperidinyl)-1 -Butanol 28kg, 4-methoxy-7H-furo[3,2-g]benzopyran-7-one 28kg, 1-methylhexahydroazepin-4-one hydrochloride 46kg, Trimethylene carbonate monomer 13kg.

[0027] The preparation method of the environment-friendly 90°C polyvinyl chloride cable insulation material in this example is prepared by a general method in the field: 2-phenyl-2,3-diazaspiro[4.5]decane-1,4-di Ketone, 2-(phosphonooxy)acrylic acid cyclohexylamine salt, 1,3-butanedioneamine, 1-acetyl-2-imidazolinone, ethyl acetylacetonate, 1,1-diphenyl- 4-(1-piperidinyl)-1-butanol, 4-methoxy-7H-furo[3,2-g]benzopyran-7-one, 1-methylhexahydroazepine - 4-keto hydrochloride and trimethylene carbonate monomers are mixed on a mixer for ...

Embodiment 2

[0029] Weigh the following raw materials in parts by weight: 23 kg of 2-phenyl-2,3-diazaspiro[4.5]decane-1,4-dione, 2-(phosphonooxy)acrylic acid cyclohexylamine salt 32kg, 1,3-butanedioneamine 20kg, 1-acetyl-2-imidazolinone 20kg, ethyl acetylacetonate 28kg, 1,1-diphenyl-4-(1-piperidinyl)-1 -Butanol 22kg, 4-methoxy-7H-furo[3,2-g]benzopyran-7-one 32kg, 1-methylhexahydroazepin-4-one hydrochloride 40kg, Trimethylene carbonate monomer 16kg.

[0030] The preparation method of the environment-friendly 90°C polyvinyl chloride cable insulating material in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0032] Weigh the following raw materials in parts by weight: 26 kg of 2-phenyl-2,3-diazaspiro[4.5]decane-1,4-dione, 2-(phosphonooxy)acrylic acid cyclohexylamine salt 35kg, 1,3-butanedioneamine 14kg, 1-acetyl-2-imidazolinone 24kg, ethyl acetylacetonate 31kg, 1,1-diphenyl-4-(1-piperidinyl)-1 -Butanol 25kg, 4-methoxy-7H-furo[3,2-g]benzopyran-7-one 36kg, 1-methylhexahydroazepine-4-one hydrochloride 43kg, Trimethylene carbonate monomer 10kg.

[0033] The preparation method of the environment-friendly 90°C polyvinyl chloride cable insulating material in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com