Flannelette lint printing and dyeing device

A technology of fleece and fluff, which is applied in the field of printing and dyeing equipment, can solve the problems of large thickness of fluff flannelette, easy pre-wetting of fabrics, and affecting printing and dyeing quality, and achieve the effects of improving work efficiency, speeding up pre-wetting speed, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

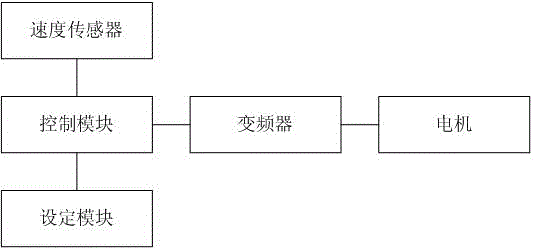

[0030] Such as figure 1 As shown, the present invention discloses a flannelette printing and dyeing device, which includes a frame, a motor, a frequency converter, a drive roller, a steam box, a first air injection module, a second air injection module, a speed sensor, a setting module and a control module, wherein , the motor is electrically connected to a control module through a frequency converter, and the control module is electrically connected to a setting module and a speed sensor respectively;

[0031] The motors are all arranged on the frame, and are connected with the drive roller in transmission, and are used to drive the drive roller to rotate;

[0032] The transmission roller is used for conveying cloth;

[0033] The speed sensor is arranged on the transmission roller to sense the conveying speed of the cloth and transmit it to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com